Description of the continuous feeding

15

2

© WASP S.r.l.

2 DESCRIPTION OF THE CONTINUOUS FEEDING

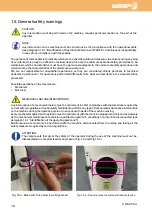

The Continuous Feeding System (or CFS for short) is the new WASP product for the ceramic sector.

The CFS is the world’s first continuous supply system for dense fluid materials for additive manufacturing that

replaces the limited capacity tank with a virtually infinite power system.

The CFS can be fed continuously without ever interrupting the printing process. The material, after being mixed

and brought to the correct consistency for printing, can then be introduced before the start of the system from

the circular inlet hole during the printing phase.

However, it no longer matters that the material is compacted and degassed before being introduced, since the

continuous movement of the mixer can easily remove all the air bubbles. An outcome that is difficult to achieve

with standard tanks.

The lower transport area has an auger that has the task of pushing the material up to the extruder mounted on the

printer. The connection PTFE/INOX tube is in fact solid enough to work in harmony with the whole system without

creating any particular effort either for the 3D printer or for the CFS.

All areas exposed to contact with the wet material are made of resistant stainless steel in order to prevent

oxidation. The system can be easily disassembled and is precisely designed for cleaning and maintenance.

Fig. 2 - Continuous feeder