5.12 DC Brake with External Zero Speed

Sensor

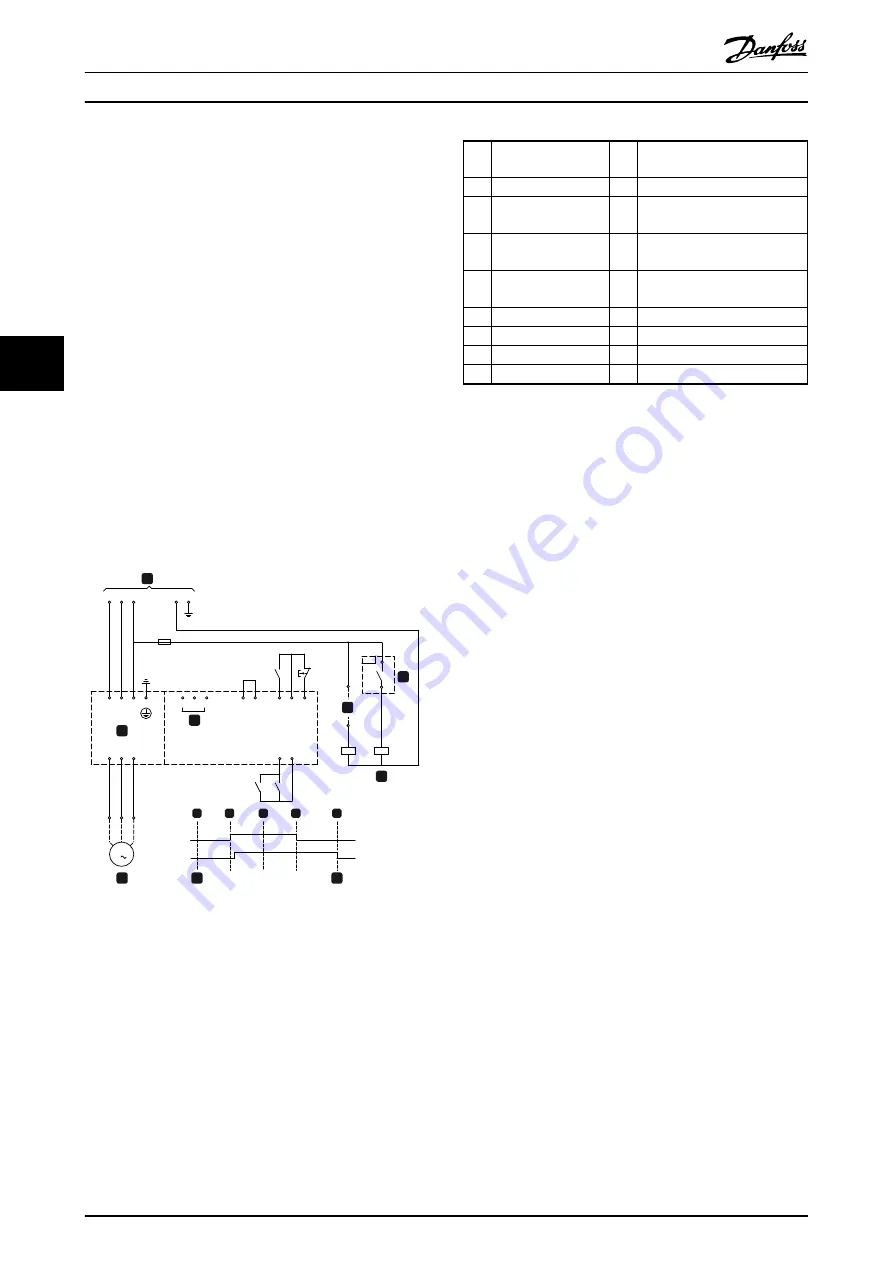

For loads which may vary between braking cycles, there

are benefits in using an external zero-speed sensor to

interface with the MCD 500 for brake shut-off. This control

method ensures that the MCD 500 braking will always shut

off when the motor has reached a standstill, thus avoiding

unnecessary motor heating.

The following schematic diagram shows how you can use

a zero-speed sensor with the MCD 500 to turn the brake

function off at motor standstill. The zero-speed sensor (-

A2) is often referred to as an under-speed detector. Its

internal contact is open at zero-speed and closed at any

speed above zero-speed. Once the motor has reached a

standstill, the MCD 500 will go into Emergency Stop mode

and remain in this state until the next start command is

given (i.e. next application of –KA1).

The MCD 500 must be operated in remote mode and

3-3

Input A Function

must be set to emergency stop.

-F1

L3

L2

L1

N

E

-KA1

L1

L2

L3

E

T1

T2

T3

A5

A4

A6

15

16

17

18

25

11

16

-KA1

-KA2

-KA1

-KA2

T3

T2

T1

M

3

-KA2

-KA1

-A2

177HA6

19.

10

4

1

3

2

5

A

B

C

D

E

6

7

5

8

Illustration 5.14

1

Soft starter

4

Emergency stop mode (shown

on starter display)

2

Control voltage

A

Off (ready)

15,

16

Start

B

Start

17,

18

Stop

C

Run

25,

18

Reset

D

Stop

2

Motor

E

Zero speed

3

Three-phase supply

5

Start signal (2, 3, or 4-wire)

6

Zero speed detect

7

Zero speed sensor

Table 5.15

For details on configuring DC Brake, see

.

NOTE

When using DC brake, the mains supply must be

connected to the soft starter (input terminals L1, L2, L3) in

positive phase sequence and

2-1 Phase Sequence

must be

set to

Positive only

.

5.13 Soft Braking

For high inertia loads the MCD 500 can be configured for

soft braking.

In this application the MCD 500 is employed with forward

run and braking contactors. When MCD 500 receives a

start signal (button S1), it closes the forward run contactor

(KM1) and controls the motor according to the

programmed primary motor settings.

When the MCD 500 receives a stop signal (button S2), it

opens the forward run contactor (KM1) and closes the

braking contactor (KM2) after a delay of approximately 2-3

seconds (KT1). KA3 is also closed to activate the secondary

motor settings, which should be user programmed for the

desired stopping performance characteristics.

When motor speed approaches zero, the external shaft

rotation sensor (A2) stops the soft starter and opens the

braking contactor (KM2).

Some shaft rotation sensors perform a self-test upon

power-up and momentarily close the output relay. In these

cases, also install a delay timer (KT3).

Application Examples

MCD 500 Operating Instruction

42

MG17K402 - VLT

®

is a registered Danfoss trademark

5

5