AAC uses two algorithms, one to measure the motor's

characteristics and one to control the motor. The MCD 500

uses the first start to determine the motor's characteristics

at zero speed and at maximum speed. During each

subsequent start and stop, the starter dynamically adjusts

its control to ensure the motor's actual performance

matches the selected profile throughout the start. The

starter increases power to the motor if the actual speed is

too low for the profile, or decreases power if the speed is

too high.

5.3 Starting Modes

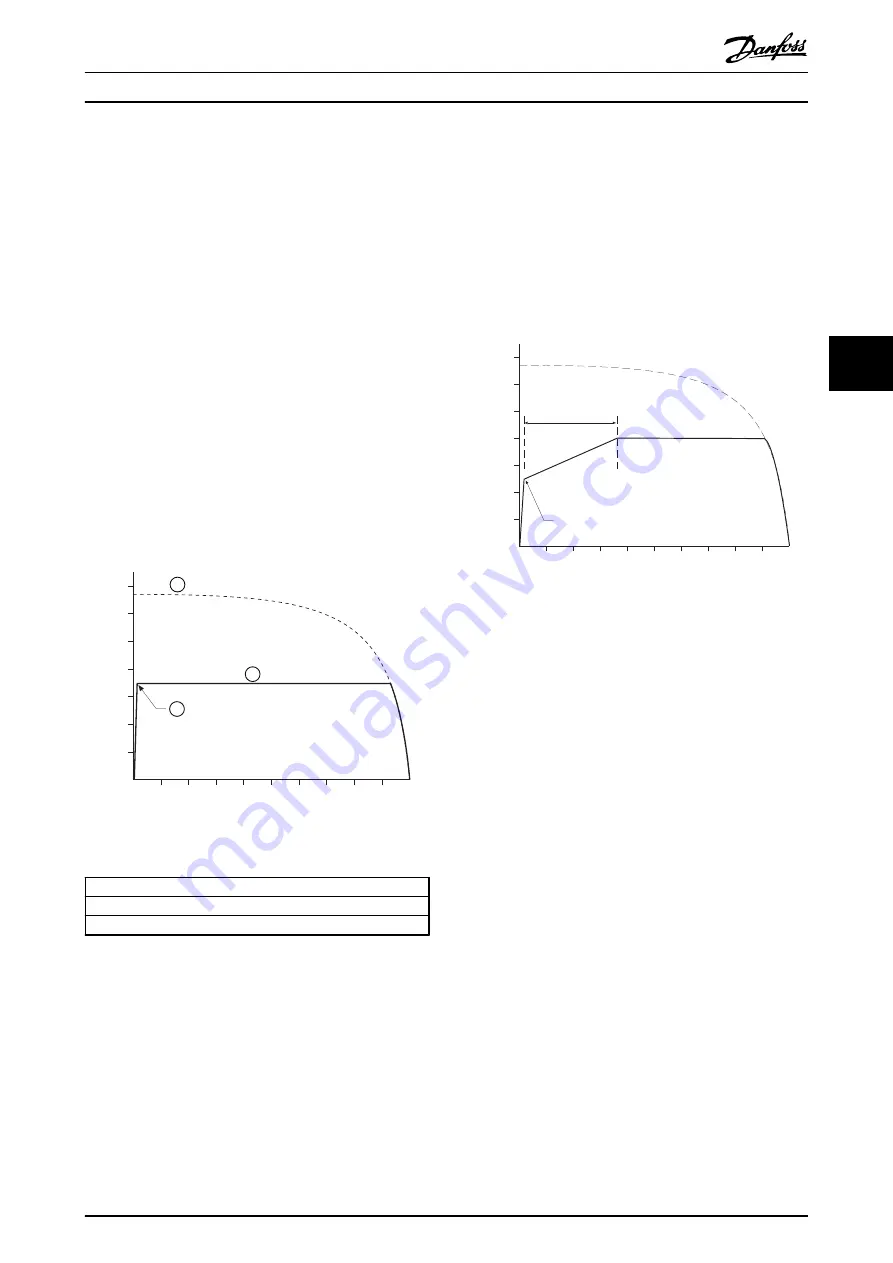

5.3.1 Constant Current

Constant current is the traditional form of soft starting,

which raises the current from zero to a specified level and

keeps the current stable at that level until the motor has

accelerated.

Constant current starting is ideal for applications where

the start current must be kept below a particular level.

700%

600%

500%

300%

100%

400%

200%

10%

20% 30% 40% 50%

Rotor speed (% full speed)

60% 70% 80% 90% 100%

17

7

H

A

2

8

9

.1

1

Cur

re

nt

(%

mo

tor

f

ull

loa

d

c

ur

re

nt

)

1

3

2

Illustration 5.2

1:

1-5 Initial current

2:

1-4 Current limit

3: Full voltage current

Table 5.1

5.3.2 Current Ramp

Current ramp soft starting raises the current from a

specified starting level (1) to a maximum limit (3), over an

extended period of time (2).

Current ramp starting can be useful for applications where:

•

the load can vary between starts (for example a

conveyor which may start loaded or unloaded).

Set

1-5 Initial Current

to a level that will start the

motor with a light load, and

1-4 Current Limit

to a

level that will start the motor with a heavy load.

•

the load breaks away easily, but starting time

needs to be extended (for example a centrifugal

pump where pipeline pressure needs to build up

slowly).

•

the electricity supply is limited (for example a

generator set), and a slower application of load

will allow greater time for the supply to respond.

700%

600%

500%

300%

100%

400%

200%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

177HA290.

10

CURRENT (% Mo

tor F

ull Load Cur

rent)

ROTOR SPEED (% Full Speed)

Full Voltage Stator Current

Current Limit (e.g. Par. 2 = 400% x FLC)

Initial Current (e.g. Par. 3 = 250% x FLC)

Ramp Time

(eg Par. 4 = 10 secs)

Illustration 5.3

5.3.3 AAC Adaptive Acceleration Control

To use AAC Adaptive Acceleration Control to control

starting performance:

1.

Select Adaptive Control in

1-3 Start Mode

.

2.

Set

1-6 Start Ramp Time

.

3.

Select the desired profile in

1-13 Adaptive Start

Profile

.

4.

Set

1-4 Current Limit

sufficiently high to allow a

successful start. The first AAC start will be a

Constant Current start. This allows the MCD 500

to learn the characteristics of the connected

motor. This motor data is used by the MCD 500

during subsequent AAC Adaptive Acceleration

Control starts.

Application Examples

MCD 500 Operating Instruction

MG17K402 - VLT

®

is a registered Danfoss trademark

31

5

5