70%

60%

50%

30%

10%

40%

Time

V

olt

a

g

e

(%

full

volt

a

g

e)

20%

80%

90%

100%

177HA509.10

1

Illustration 5.6

1:

1-11 Stop Time

Table 5.4

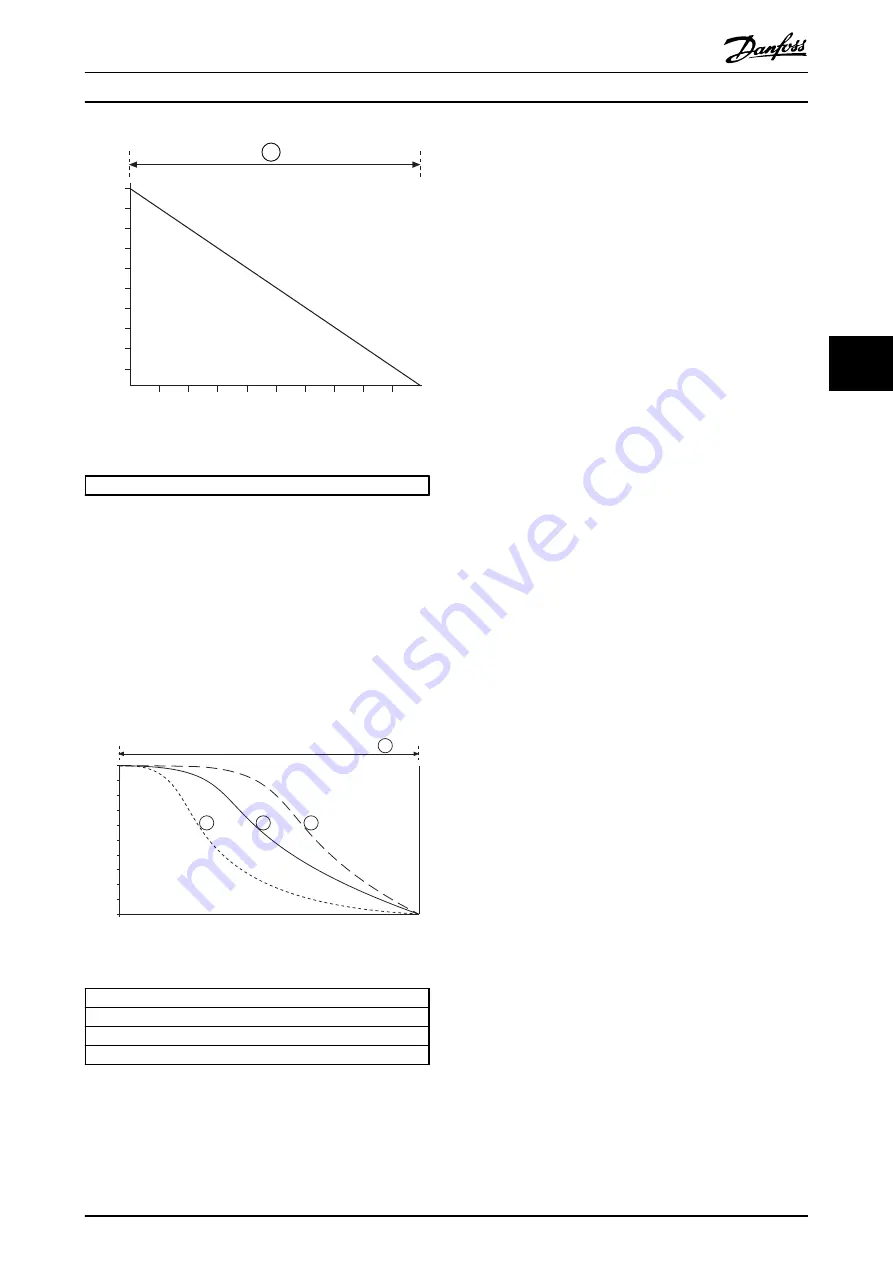

5.4.3 AAC Adaptive Acceleration Control

To use AAC Adaptive Acceleration Control to control

stopping performance:

1.

Select Adaptive Control in

1-10 Stop Mode

.

2.

Set

1-11 Stop Time

.

3.

Select the required profile in

1-14 Adaptive Stop

Profile

.

0

10%

20%

30%

40%

50%

Time

S

p

ee

d

60%

70%

80%

90%

100%

17

7

H

A

51

0

.1

0

1

2

4

3

Illustration 5.7

1. Early deceleration

2. Constant deceleration

3. Late deceleration

4.

1-10 Stop Time

Table 5.5 1-14 AAC Adaptive Stop Profile

NOTE

Adaptive control does not actively slow the motor down

and will not stop the motor faster than a coast to stop. To

shorten the stopping time of high inertia loads, use brake.

The first AAC Adaptive Deceleration Control stop will be a

normal soft stop. This allows the MCD 500 to learn the

characteristics of the connected motor. This motor data is

used by the MCD 500 during subsequent Adaptive Control

stops.

NOTE

Adaptive Control will control the load according to the

programmed profile. Stopping current will vary according

to the selected deceleration profile and stop time.

If replacing a motor connected to an MCD 500

programmed for AAC Adaptive Control starting or

stopping, or if the starter has been tested on a different

motor prior to actual installation, the starter will need to

learn the characteristics of the new motor. The MCD 500

will automatically re-learn the motor's characteristics if

1-1

Motor Full Load Current

or

1-12 Adaptive Control Gain

is

changed.

5.4.4 Brake

Brake reduces the time the motor requires to stop.

During braking an increased noise level from the motor

may be audible. This is a normal part of motor braking.

CAUTION

If the brake torque is set too high, the motor will stop

before the end of the brake time and the motor will suffer

unnecessary heating which could result in damage. Careful

configuration is required to ensure safe operation of the

starter and motor.

CAUTION

A high brake torque setting can result in peak currents up

to motor DOL being drawn while the motor is stopping.

Ensure protection fuses installed in the motor branch

circuit are selected appropriately.

NOTE

Brake operation causes the motor to heat faster than the

rate calculated by the motor thermal model. If you are

using brake, install a motor thermistor or allow sufficient

restart delay (

2-11 Restart Delay

).

When brake is selected, the MCD 500 uses DC injection to

slow the motor.

Application Examples

MCD 500 Operating Instruction

MG17K402 - VLT

®

is a registered Danfoss trademark

33

5

5