88

89

MULTIFUNCTION

SERIES

EQUIPMENT

MULTIFUNCTION

SERIES

EQUIPMENT

◆

3M Power cable

◆

200 Amp Electrode Holder With 3M cable

◆

200 Amp earth Clamp With 3M cable

◆

4M TIG Torch WP26

◆

Plasma Torch 4.5m AG60

◆

Air Regulator

◆

3.5M Gas Hose

◆

Operating Manual

1.6 Packaged Items

O241/O251

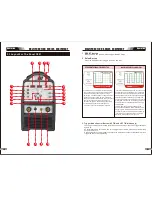

2.1 Layout For The Panel O241

5

12

13

14

16

8

4

3

7

6

2

1

9

10

11

15

17

21

20

19

18

8. Programming Parameter Indicators

6. Time Indicator (s)

7. Frequency Indicator (Hz)

These indicator lights will illuminate when programming.

Time indicator , when setting programm in gas pre-flow, up slope, down slope and gas

post-flow, this indicator will be on.

Frequency indicator, when the setting programm in pulse frequency ,this indicator will

be on.

2. Current Indicator

When setting programm in the peak current, base current, ending current and rem , this

current indicator will be on.

3. Percentage Indicator

(%)

Percentage indicator, when setting programm in pulse duty cycle , this indicator will be

on .

9. Hot Start

Arcforce Correction

Hot Start

Function reliably ignites the electrode

and melts perfectly to ensure the best quality

even at the start of the seam. this solution makes

lack of fusion and cold welds a thing of the past

and significantly reduces weld reinforcement.

Adjust the hot start current here and the time here.

During the welding process, arcforce prevents

the electrode sticking in the weld pool with

increases in current. this makes it easier to weld

large-drop melting electrode types at low current

strengths with a short arc in particular.

I

t

5. Thermal Overload Indicator Light

This welding power source is protected by a self resetting thermostat. The indicator will

illuminate if the duty cycle of the power source has been exceeded. Should the thermal

overload indicator illuminate the output of the power source will be disabled. Once the

power source cools down this light will go OFF and the over temperature condition will

automatically reset. Note that the mains power switch should remain in the on position

such that the fan continues to operate thus allowing the unit to cool sufficiently. Do not

switch the unit off should a thermal overload condition be present.

Operation

Operation

4. Power ON Indicator

The POWER ON indicator illuminates when the ON/OFF switch is in the ON position and

the correct mains voltage is present.

1. Digital Ammeter / Parameter meter

The digital Ammeter is used to display the actual output current of the power source. It is

also used to display Parameters in Programming Mode.

Depending on the Programming Parameter selected, the status indictor adjacent to the

Ammeter will illuminate to show the units of the programming parameter.

When welding, the Ammeter will display actual welding current.