2.5 Setup For STICK (MMA) Welding

WARNING

CAUTION

CAUTION

Before connecting the work clamp to the work and

inserting the electrode in the electrode holder make

sure the mains power supply is switched off.

Remove any packaging material prior to use. Do not

block the air vents at the front or rear of the Welding

Power Source.

Loose welding terminal connections can cause

overheating and result in the male plug being fused

in the bayonet terminal.

AC/DC

SERIES

EQUIPMENT

AC/DC

SERIES

EQUIPMENT

Operation

Operation

27

26

power supply

2.6 Set-up For LIFT TIG (GTAW) Welding

WARNING

Before any welding is to begin, be sure to wear all

appropriate and recommended safety equipment.

Antistick

A

nt

is

ti

ck

U

I

13. Hot Start

14. Arcforce Correction

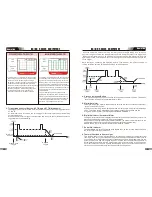

Hot Start

Function reliably ignites the electrode

and melts perfectly to ensure the best quality

even at the start of the seam. this solution makes

lack of fusion and cold welds a thing of the past

and significantly reduces weld reinforcement.

Adjust the hot start current here and the time here.

During the welding process, arcforce prevents

the electrode sticking in the weld pool with

increases in current. this makes it easier to weld

large-drop melting electrode types at low current

strengths with a short arc in particular.

Anti-stick prevents the electrode from annealing.

If the electrode sticks in spite of the arcrorce device, the

machine automatically switches over to the minimum

current within about 1 second to prevent the electrode

electrode and electrode holder to protect the welder.

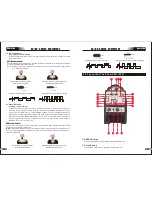

For

Alkaline

Electrode

,

connect

the electrode

holder

to

the

positive

welding

termimal

Electrode

,

please connect

the

electrode

holder

to

the

negative

welding

termimal

and

manufacturer. Welding current flows from the Power Source via heavy duty bayonet type

terminals. It is essential, however, that the male plug is inserted and turned securely to

achieve a sound electrical connection. Select STICK mode with the process selection

control.

and connect the work lead

to the negative

welding

terminal

,

while

for

the

Acid

connect

the

work

lead

to

the

positve

welding

terminal

.

If

in

doubt consult the electrode

f r o m o v e r h e a t i n g . I n o r d e r t o e a s i l y s e p a r a t e t h e