AC/DC

SERIES

EQUIPMENT

AC/DC

SERIES

EQUIPMENT

Summary

2.1 Layout For The Panel V1841

13

12

Operation

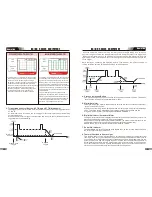

1.6 Duty Cycle

The rated duty cycle of a Welding Power Source, is a statement of the time it may be

operated at its rated welding current output without exceeding the temperature limits of

the insulation of the component parts. To explain the 10 minute duty cycle period the

following example is used. Suppose a Welding Power Source is designed to operate at

a 50% duty cycle, 300 amperes at 32 volts. This means that it has been designed and

built to provide the rated amperage (300A) for 5 minutes, i.e. arc welding time, out of

every 10 minute period (50% of 10 minutes is 5 minutes). During the other 5 minutes of

the 10 minute period the Welding Power Source must idle and be allowed to cool. The

thermal cut out will operate if the duty cycle is exceeded.

◆

3M Power cord

◆

200 Amp electrode holder with 3M cable

◆

200 Amp earth clamp with 3M cable

◆

4M TIG Torch WP26

◆

3M Gas Hose

◆

Operating Manual

1.7 Packaged Items

V1841/V241

◆

3M Power cord

◆

300 Amp electrode holder with 3M cable

◆

300 Amp earth clamp with 3M cable

◆

4M TIG Torch WP18

◆

3M Gas Hose

◆

Operating Manual

V341

D

ut

y C

yc

le

(P

E

R

C

E

N

TA

G

E

)

Welding Current(AMPS)

1 0 0

1 20

1 4 0

1 6 0

1 8 0

2 0 0

220

0

1 0

2 0

3 0

4 0

5 0

6 0

7 0

80

9 0

1 00

2 4 0

2 6 0

2 8 0

3 0 0

3 2 0

0

Safe Operating Region

(TIG&STICK)

V1841 TIG

V1841 STICK

D

ut

y C

yc

le

(P

E

R

C

E

N

TA

G

E

)

Welding Current(AMPS)

1 0 0

1 20

1 4 0

1 6 0

1 8 0

2 0 0

220

0

1 0

2 0

3 0

4 0

5 0

6 0

7 0

8 0

9 0

1 0 0

2 4 0

2 6 0

2 8 0

3 0 0

3 2 0

0

V241 STICK/TIG

V341

STICK/TIG

3

2

1

4

8

7

5

14

15

16

17

6

12

13

9

10

11

3

2

1

4

8

7

5

14

15

16

17

6

12

13

9

10

11

Safe Operating Region

(TIG&STICK)