42

43

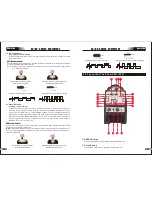

2.3 Layout For The Panel E301/E401

11

22

3

4

9

5

7

6

8

10

1. Power Indicator

The green power indicator will be illuminated when the welder is turned ON and indicates

the presence of power.

WARNING

DO NOT TOUCH the electrode wire while it is being fed through the system. The electrode

wire will be at welding voltage potential.

3.Prevent Electric Shock

The VRD button on the front panel is illuminated when pressing the VRD indicator, at the

same time the no-load voltage is lower than 15V and the output terminal is not harmful

to the human body.When the button is pressed again, the VRD indicator light goes out,

and the output is now at 71V.

Operation

STICK

SERIES

EQUIPMENT

STICK

SERIES

EQUIPMENT

2. Thermal Overload Indicator Light

This welding power source is protected by a self resetting thermostat. The indicator will

illuminate if the duty cycle of the power source has been exceeded. Should the thermal

overload indicator illuminate the output of the power source will be disabled. Once the

power source cools down this light will go OFF and the over temperature condition will

automatically reset. Note that the mains power switch should remain in the on position

such that the fan continues to operate thus allowing the unit to cool sufficiently. Do not

switch the unit off should a thermal overload condition be present.

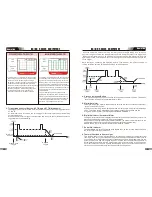

5.Negative Control

The negative control is used to minus setting parameter for selected function from 6.

6.Selecting Function Button

Press and release this button to change the selected weld functions mode from welding

current to hotstart to start time to ARC Force from the digital display.

7.Positive Control

The positive control is used to plus setting parameter for selected function from 6.

8. Negative Welding Output Terminal

The negative welding terminal is used to connect the welding output of the power source

to the appropriate welding accessory such as electrode holder. It is essential, however,

that the male plug is inserted and turned securely to achieve a sound electrical

connection.

9. Shielding Gas Outletl

The Shielding Gas Outlet located on the front panel is a fast connection of a suitable TIG

Torch.

10. 5 Pin Control Socket

The 5 pin receptacle is used to connect a trigger switch or remote control to the welding

Power Source circuitry.

To make connections, align keyway, insert plug, and rotate threaded collar fully clockwise.

11. Positive Welding Output Terminal

The positive welding terminal is used to connect the welding output of the power source

to the appropriate welding accessory such as earth clamp. It is essential, however, that

the male plug is inserted and turned securely to achieve a sound electrical connection.

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug

being fused in the bayonet terminal.

3.Weld Process Selection Button

Press and release this button to change the selected weld process mode from LIFT TIG

to STICK. The weld process will change to the next process in the sequence each time

to identify LIFT TIG or STICK process mode.

4.Digital Display

The digital meter is used to display the pre-set (preview) amperage for welding, the

preset parameters in Hot start, start time amd Arc force and actual welding amperage of

the power source when welding.

Operation

the button is pressed and released. The green indicators next to the button will illuminate