Installation 5

0020224355_00 HOME Installation and maintenance instructions

13

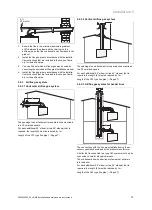

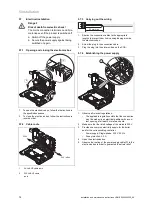

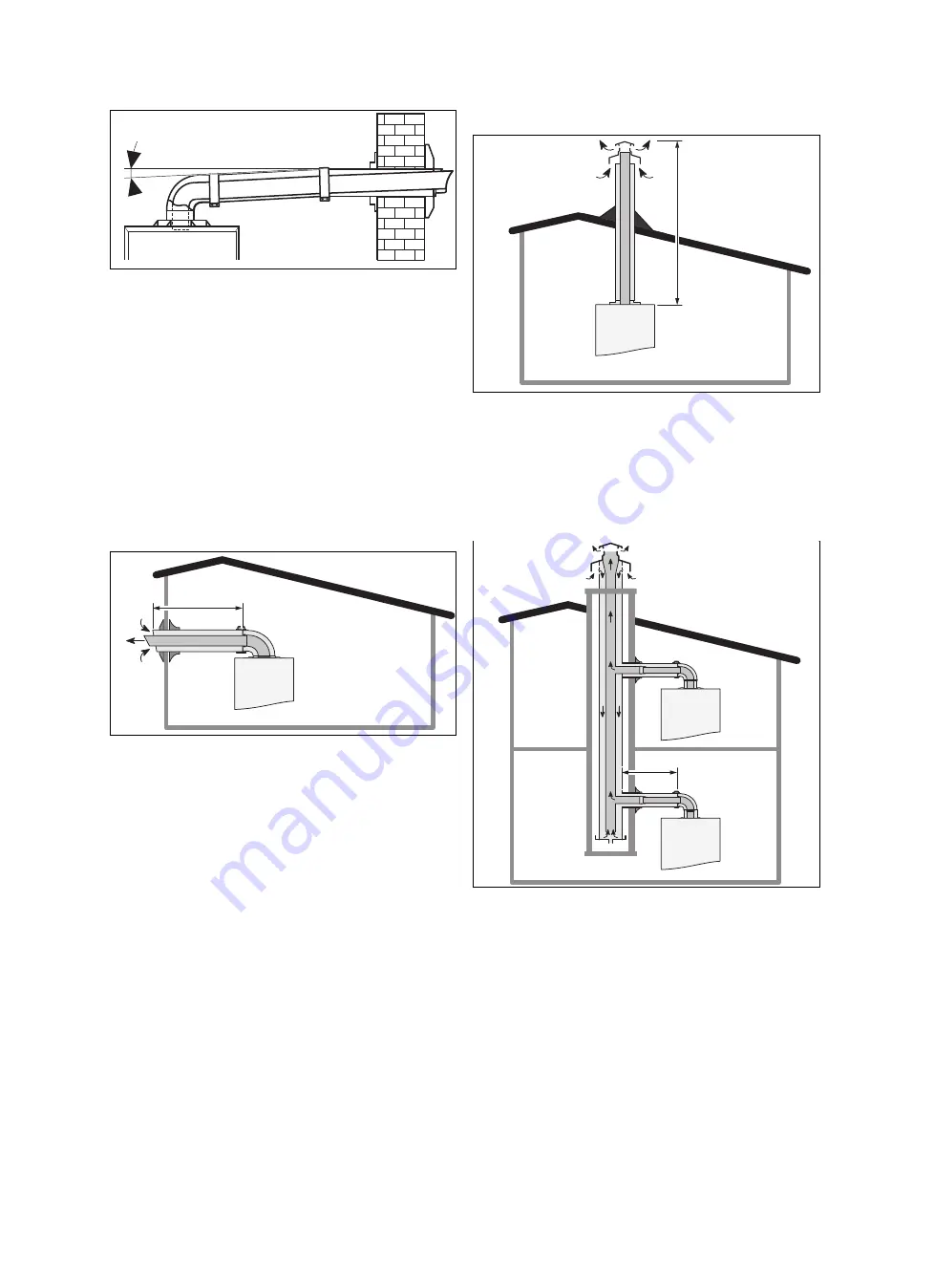

50 mm/1m

5 %

1.

Ensure that there is a minimum downward gradient

of 5% between the elbow and the terminal on the

air/flue pipe so that the condensate can flow back to the

product.

2.

Install the flue gas pipe in accordance with the installa-

tion instructions that are included in the scope of deliv-

ery for the air/flue pipe.

3.

You can find out which air/flue pipes may be used by

consulting the enclosed air/flue pipe installation manual.

4.

Install the flue gas pipe in accordance with the installa-

tion instructions that are included in the scope of deliv-

ery for the air/flue pipe.

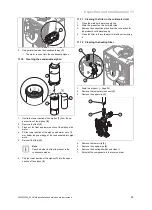

5.6.3

Air/flue gas system

5.6.3.1 Horizontal air/flue gas system

L

The openings in an attachment for separate lines must lead

to a 50 cm-sided square.

For each additional 90° elbow (or two 45° elbows) that is

required, the length

(L)

must be reduced by 1 m.

Length of the C13 type flue pipe (

→

Page 47)

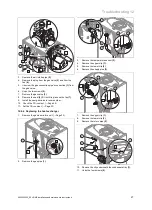

5.6.3.2 Vertical air/flue gas system

L

The openings in an attachment for separate lines must lead

to a 50 cm-sided square.

For each additional 90° elbow (or two 45° elbows) that is

required, the length

(L)

must be reduced by 1 m.

Length of the C33 type flue pipe (

→

Page 47)

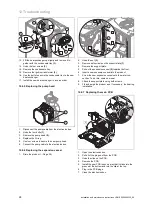

5.6.3.3 Air/flue gas system for header lines

L

The connections with the line are established using the ac-

cessory specially developed by the product manufacturer.

A boiler that is connected to a type C43 system must only be

connected to natural draught chimneys.

The condensate from header line systems must not drain

into the boiler.

For each additional 90° elbow (or two 45° elbows) that is

required, the length

(L)

must be reduced by 1 m.

Length of the C43 type flue pipe (

→

Page 47)

Summary of Contents for home combi

Page 51: ......