5 Installation

12

Installation and maintenance instructions HOME 0020224355_00

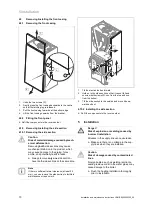

5.4

Connecting the condensate drain pipework

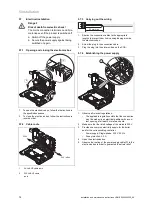

1

2

3

2

▶

Follow the instructions listed here and observe any legal

directives and local regulations on condensate discharge.

▶

Use PVC or another material that is suitable for draining

the non-neutralised condensate.

▶

If you cannot guarantee that the materials from which

the drain lines are made are suitable, install a system for

neutralising the condensate.

▶

Ensure that the connection between the condensate

drain pipework and the drain hose is not air-tight.

Note

The condensate drain pipework must have a

continuous fall (45 mm per metre) and should

whenever possible terminate at a suitable

drain point within the heated envelope of the

building that will remain frost free under long

periods of low external temperatures.

▶

Connect the condensate siphon

(1)

. Use the supplied

drain hose

(2)

for this.

▶

Connect condensate drain pipework (21.5 mm, not in-

cluded in the scope of delivery)

(3)

to the drain hose

(2)

.

▶

During installation remove all burs from inside of cut pipe

work and avoid excessive adhesive which may trap small

pockets of water close to the pipe wall which can freeze

and build into a larger ice plug.

▶

As with other pipe work insulate the condensate dis-

charge pipe to minimise any risk of freezing and beware

when crossing cavities that the fall is maintained and the

pipe sleeved.

You can find further information in BS 6789: "Specification

for installing and maintaining gas-fired boilers with a nominal

heat loading less than 70 kW".

5.5

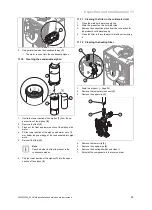

Connecting the drain cock

1

▶

Connect a hose to the drain cock

(1)

and guide the free

end of the hose to a suitable outflow location.

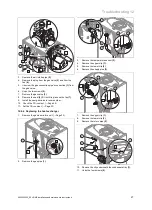

5.6

Flue gas installation

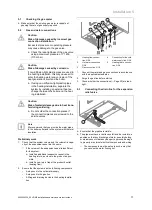

5.6.1

Replacing the connection piece for the

air/flue pipe

Note

As standard, the product is equipped with a con-

nection piece with a diameter of 60/100 mm.

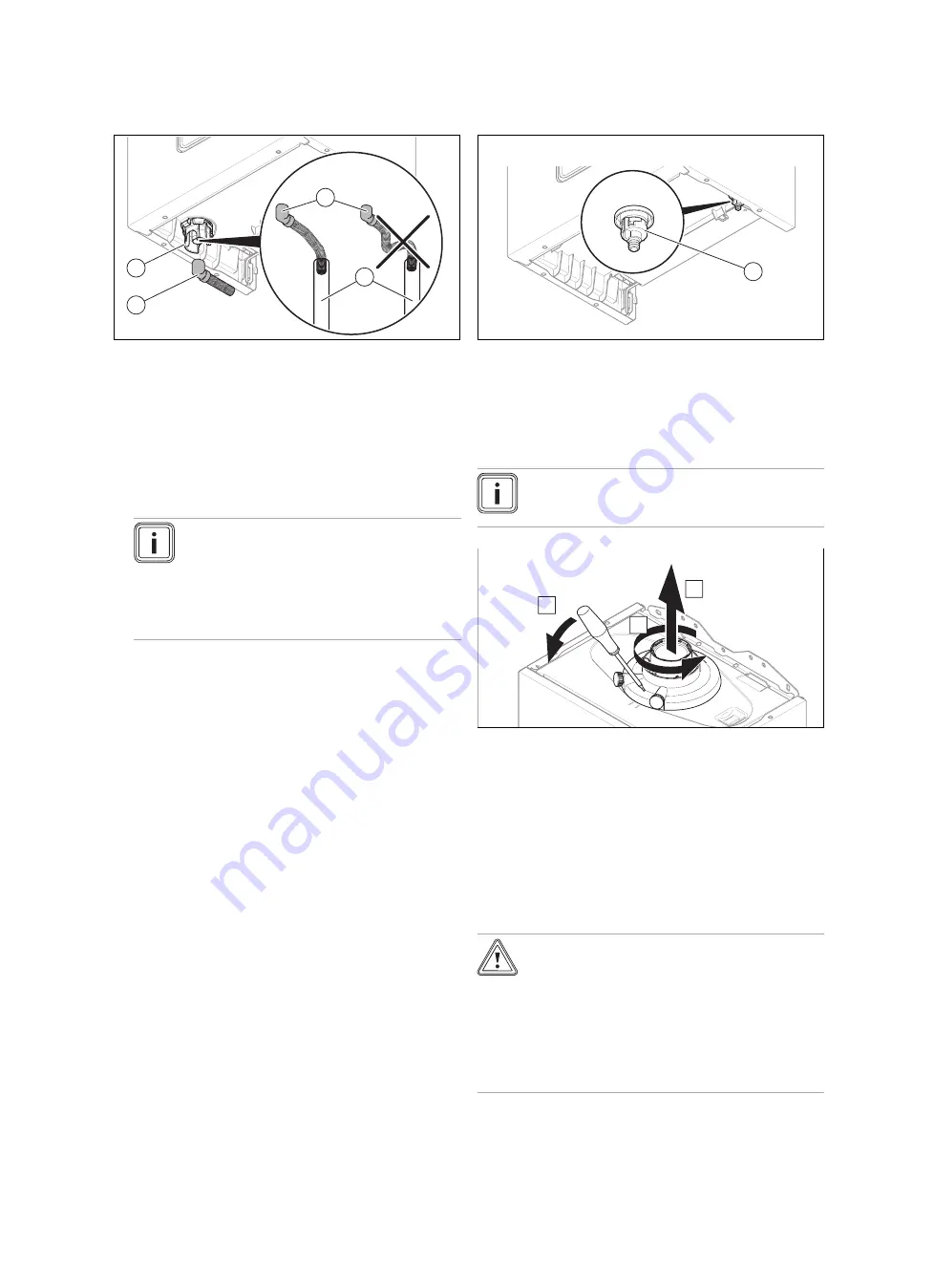

A

B

C

1.

Insert a screwdriver into the slot between the measuring

stub pipes.

2.

Push in the screwdriver carefully

(A)

.

3.

Turn the connector anticlockwise

(B)

as far as it will go

and then remove it by pulling it upwards

(C)

.

4.

Insert a new connector. In doing so, pay attention to the

latching lugs.

5.

Turn the connection piece clockwise so that it clicks into

position.

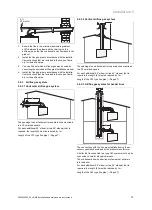

5.6.2

Installing the air/flue pipe

Caution.

Risk of poisoning due to escaping flue

gas.

Mineral-oil-based greases can damage the

seals.

▶

Instead of grease, use only water or com-

mercially available soft soap to aid install-

ation.

Summary of Contents for home combi

Page 51: ......