Inspection and maintenance 10

0020244995_02

ecoTEC

pro

Installation

and

maintenance

instructions

27

Note

Instead of grease, use only water or com-

mercially available soft soap to aid installa-

tion.

13. Insert the flow and return connections into the heat

exchanger as far as they will go.

14. Make sure that the brackets are seated correctly on the

flow and return connections.

15. Install the compact thermal module. (

→

Page 29)

16. Fill and purge the product and, if necessary, the heating

installation. (

→

Page 19)

9.6.4

Replacing the expansion vessel

1.

Drain the product. (

→

Page 30)

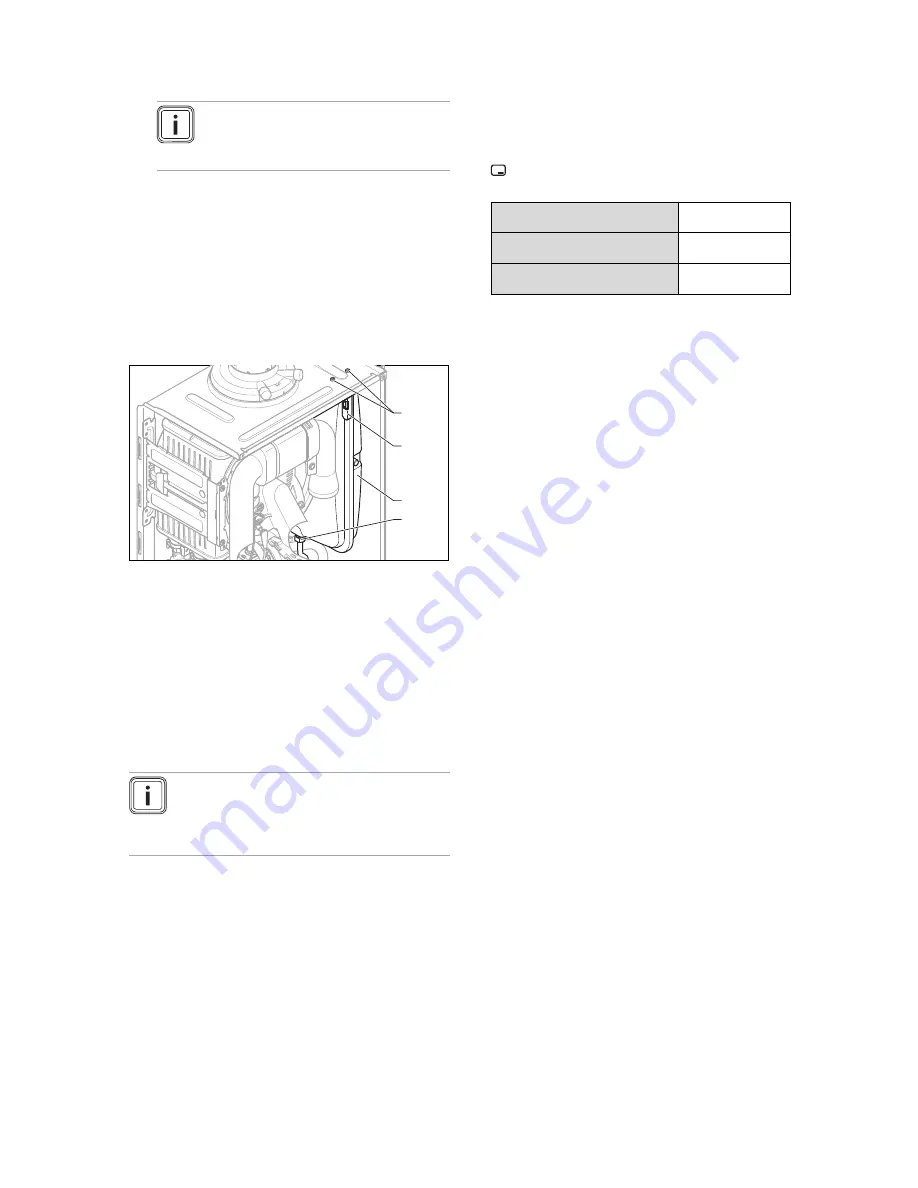

1

2

3

4

2.

Undo the screwed connection

(4)

.

3.

Remove both screws

(1)

on the support plate

(2)

.

4.

Remove the support plate

(2)

.

5.

Pull out the expansion vessel

(3)

towards the front.

6.

Insert the new expansion vessel into the product.

7.

Screw the new expansion vessel to the water connec-

tion. Use a new seal for this.

8.

Attach the support plate using both screws

(1)

.

9.

Fill and purge the product and, if necessary, the heating

installation. (

→

Page 19)

9.6.5

Replacing the PCB or the display

Note

If you only replace one component, when the

product is switched on, the new component ad-

opts the parameters that were previously set from

the component that was not replaced.

1.

Open the electronics box. (

→

Page 15)

2.

Replace the PCB or display according to the assembly

and installation instructions supplied.

3.

Close the electronics box.

9.6.6

Replacing the PCB and the display

1.

Open the electronics box. (

→

Page 15)

2.

Replace the PCB and display according to the

assembly and installation instructions supplied.

3.

Close the electronics box.

4.

Press the on/off button on the product. (

→

Page 18)

◁

You are automatically taken to

D.093

to set the

device specific number.

5.

Set the correct value for the relevant product type in ac-

cordance with the table below and confirm by pressing

.

Product type number

VUW 246/5-3 (H-GB) ecoTEC pro

24

7

VUW 286/5-3 (H-GB) ecoTEC pro

28

22

VUW 286/5-3 (P-GB) ecoTEC pro

28

22

◁

The electronics are now set to the product type and

the parameters of all diagnostics codes are set to

default settings.

6.

Make the system-specific settings.

9.7

Completing repair work

1.

Establish the power supply.

2.

Switch the product back on if this has not yet been

done. (

→

Page 18)

3.

Install the front casing.

4.

Open all service valves and the gas isolator cock.

9.8

Checking the product for leak-tightness

▶

Check that the product is leak-tight. (

→

Page 22)

10 Inspection and maintenance

▶

You must carry out an annual inspection of the product.

The annual inspection can be effectively performed

without removing components by requesting data from

the DIA system, carrying out the simple visual checks in-

dicated in the table in the appendix and performing a flue

gas measurement. The maintenance intervals and their

scope are determined by the heating engineer based on

the condition of the boiler found during the inspection. All

inspection and maintenance work should be performed in

the order specified in the table in the appendix.

During any inspection and maintenance or after change

of parts of the combustion circuit, the following must be

checked:

–

The boiler has been installed in accordance with the rel-

evant installation instructions.

–

The integrity of the flue gas installation and flue seals is

in accordance with the relevant flue installation instruc-

tions enclosed.

–

Visual, the integrity of the boiler combustion circuit and

relevant seals (paying particular attention to the burner

door seal).

–

The gas inlet working pressure at maximum rate.

–

The gas flow rates.

–

Correctness of electrical, water and gas connections.

–

Correctness of the water pressure.

–

The condition of the whole system, in particular the con-

dition of radiator valves, evidence of leakage from the

heating system and dripping taps.

▶

Correct any faults before proceeding.