Set-up 4

0020233500_01 auroCOMPACT Installation and maintenance instructions

11

6.

Never transport the unit as illustrated above.

7.

After you have set up the unit, cut off the carrying

handles and dispose of them in accordance with the

relevant regulations.

8.

Refit the unit's front casing.

4.8

Unit installation site

Danger!

Risk of death from leaks if the product is

installed below ground level!

If the product is installed below ground level,

propane will accumulate at floor level if there

are any leaks. In this case, there is a risk of

explosion.

▶

Make sure that propane cannot escape

from the product or the gas line under

any circumstances. Install an external

solenoid valve, for example.

▶

Do not set up the unit in a room that has a very dusty

atmosphere or in a corrosive environment.

▶

Do not set up the unit in rooms in which sprays, solvents,

chlorinated cleaning agents, paint, adhesives, ammonia

compounds or other similar substances are stored or

used.

▶

Take the weight of the unit, including the water content,

into account. Look up information on this in the technical

data.

▶

Ensure that the room in which you want to set up the unit

is sufficiently protected against frost.

▶

Do not route the combustion air via the smoke outlet on

an old oil-fired floor-standing boiler as this may lead to

corrosion.

▶

If the air in the room in which you want to install the

unit contains aggressive vapours or dust (during con-

struction work, for example), ensure that the unit is

sealed/protected.

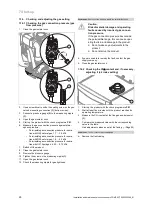

4.9

Installing the product horizontally

▶

Use the adjustable feet to set up the product horizontally.

4.10

Removing/installing the front casing

4.11

Installing/removing the side casing

A

B

C

A

2

1

▶

Refit the components in the reverse order.

4.12

Moving the electronics box into the lower or

upper position

Note

Moving the electronics box into the lower or upper

position makes it easier to access the unit's vari-

ous components.