5 Installation

14

Installation and maintenance instructions auroCOMPACT 0020233500_01

C

C

2

1

1

2

B

A

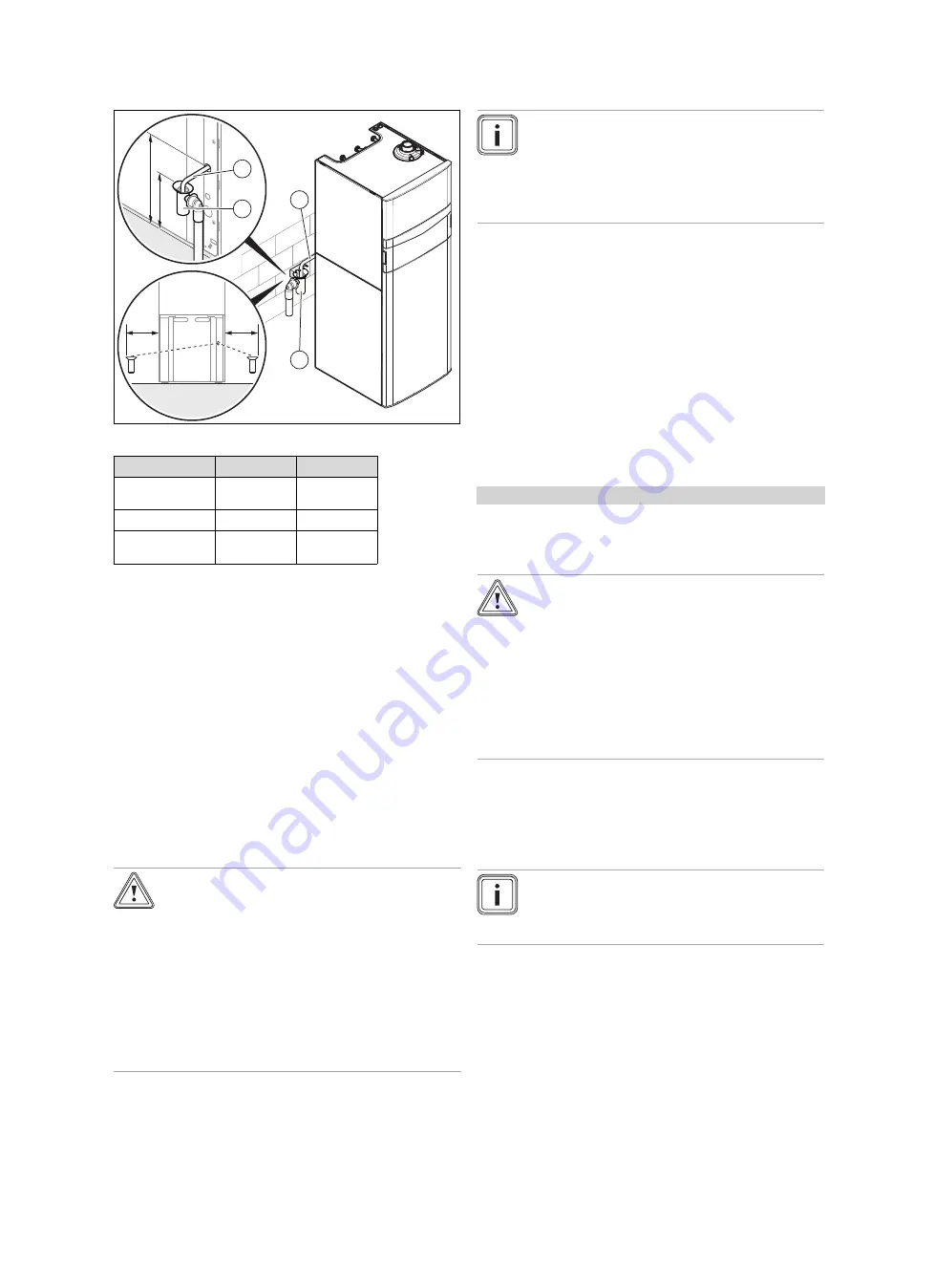

Clearances for connecting the siphon

150L

190L

Max. dimension

(A)

720 mm

960 mm

Dimension (B)

770 mm

1,010 mm

Max. dimension

(C)

300 mm

300 mm

Condensed water forms during combustion. The condensed

water discharge pipe routes this condensed water to the

waste water connection via a tundish.

▶

Use PVC or another material that is suitable for draining

the non-neutralised condensed water.

▶

Only use corrosion-resistant piping material for removing

condensate.

▶

If it cannot be guaranteed that the materials are suitable,

install a system for neutralising the condensed water.

▶

Connect the condensed water discharge pipe

(1)

to a

suitable drain siphon

(2)

.

▶

Ensure that the condensed water in the drain line is

drained properly.

5.5

Solar connection

5.5.1

General information

Caution.

Risk of voltage surge.

Overvoltage may damage the solar plant.

▶

Earth the solar circuit to provide equipo-

tential bonding and overvoltage protec-

tion.

▶

Secure earthing pipe clamps to the solar

lines.

▶

Connect the earthing pipe clamps to a

busbar using 16 mm

²

copper cable.

Note

If there is a fault in the solar system or if the solar

system is connected at a later point, this unit can

be used without being connected to the solar cir-

cuit.

In this case, set diagnostics code d.200 to 1.

▶

Ensure that the heat insulation of the lines is sufficient to

prevent excessive heat losses.

–

The outside lines are exposed to the weather and ul-

traviolet radiation and are pecked by birds, making

them particularly vulnerable; select effective protec-

tion against these risks.

▶

Maintain a minimum downward gradient in order to guar-

antee automatic draining of the solar circuit.

–

Minimum downward gradient that is to be maintained:

4 %

▶

Solder all of the pipelines.

▶

Do not use plastic pipes.

▶

Only use press connections if the temperature that is

permitted by the manufacturer is 200 °C.

Conditions

: The building has a lightning conductor.

▶

Connect the solar collectors to the lightning conductor.

5.5.2

Material for the solar pipes

Caution.

Risk of material damage caused by mech-

anical deformation or burst lines.

Due to the extremely high temperatures that

the solar fluid can reach from time to time,

plastic lines (e.g. PE pipe) may deform or

burst.

▶

Do not use plastic lines.

▶

It is preferable to use copper pipes.

Selecting a suitable line diameter has a great influence on

the solar system's efficiency. The system works with a hose

with an internal diameter of 8 mm.

5.5.3

Maximum length of the solar pipes

Note

To prevent energy losses, the hydraulic lines must

be provided with heat insulation that complies with

the applicable thermal insulation regulations.