Appendix

48

Installation and maintenance instructions auroCOMPACT 0020233500_01

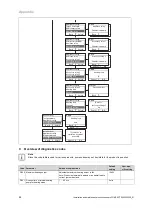

Code Parameter

Values or explanations

Default

setting

User-spe-

cific setting

D.203 Speed of solar pump 1

In %, adjustment range: 0 to 100

Not ad-

justable

D.204 Speed of solar pump 2

In %, adjustment range: 0 to 100

Not ad-

justable

D.206 Maximum cylinder temperature with

solar energy

20 … 80

℃

80 °C

D.209 Operating hours of the solar pump

In hours

Not ad-

justable

D.212 Delta T between the cylinder temper-

ature and solar panel in operation

7 … 20

℃

15

D.213 Delta T between the cylinder tem-

perature and solar panel when the

system is idle

2 … 5

℃

3

D.214 Additional filling time

From 0 to 1000 s

0 s

D.215 Additional solar pump

0 = Function deactivated

1 = Function activated

0

D.217 Collector surface area

In M

2

, from 1 to 10 M

2

: Permitted in order to determine

the filling time. 1 M

2

= 60 s

4

D

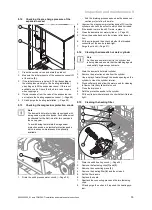

Inspection and maintenance work

–

Overview

No.

Work

Inspection

(annual)

Mainten-

ance

(at least

every

2 years)

1

Check the air/flue pipe for leak-tightness and to ensure that it is fastened correctly. Make sure

that it is not blocked or damaged and has been installed in accordance with the relevant Installa-

tion Manual.

X

X

2

Check the general condition of the unit. Remove dirt from the product and from the combustion

chamber.

X

X

3

Visually inspect the general condition of the heating block. In doing so, pay particular attention

to signs of corrosion, rust and other defects. If you notice any damage, carry out maintenance

work.

X

X

4

Check the gas connection pressure at maximum heat input. If the gas connection pressure is not

within the specified range, carry out maintenance work.

X

X

5

Check the CO

₂

content (the air ratio) of the product and, if necessary, adjust it. Keep a record of

this procedure.

X

X

6

Disconnect the product from the power mains. Check that the electrical plug connections and

other connections are seated correctly and correct these if necessary.

X

X

7

Close the gas isolator cock and the service valves.

X

8

Drain the product's heating circuit. Check the pre-charge pressure of the expansion vessel and

top up the vessel, if necessary (approx. 0.3 bar below the system filling pressure).

X

9

Allow the pressure in the hot water circuit to fall. Check the pre-charge pressure of the expan-

sion vessel in the shift-load cylinder (if installed). Correct the pressure, if necessary.

X

X

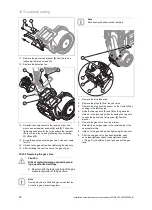

10

Check the extent to which the anode is corroded and replace it if necessary.

X

X

11

Remove the compact thermal module.

X

12

Check all seals in the combustion area, in particular the seal on the burner door. If you see any

damage, replace the seals.

X

13

Clean the heat exchanger.

X

14

Check that the burner is not damaged and, if required, replace it.

X

15

Check the condensate siphon in the product, clean and fill if necessary.

X

X

16

Install the compact thermal module.

Caution: Replace the seals.

X

17

If the volume of water is insufficient or the outlet temperature is not reached, replace the second-

ary heat exchanger if necessary.

X

18

Open the gas isolator cock, reconnect the product to the power mains and switch the product on.

X

X

19

Open the service valves, fill up the unit/heating installation so that the pressure is 1,0-1,5 bar

(depending on the static height of the system) and start the purge programme.

X