5

7. 48 inches Long of extruded grey gasket 1/8’’ X

1/2’’;

8. A 90

o

galvanized increaser 3 inches / 4 inches

elbow for the burner combustion air intake junction

with 4 inches aluminum pipe;

9. 4 inches diameter collar for aluminum combustion

air pipe and 90

o

elbow joint;

10. Half moon cover;

11. Half moon plate to fix the vent pipe on the vent

terminal assembly;

12. Plate "L";

13. 1 inches thick neoprene outside gasket;

14. One tube or high temperature sealant;

2.4)

VENT TERMINAL INSTALLATION

CAUTION

Do not forget to remove the 4 inches diameter pipe

from the 5 inches diameter pipe. The appliance can

not operate with both pipes inside each other. This

configuration is used for shipping purposes only.

2.4.1) Preparation and requirements

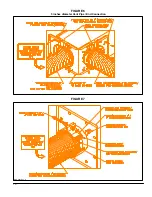

The vent terminal can be installed to accommodate

six different vent and combustion air pipe

combinations as shown on figure 3. Find a location on

an outside wall that respects all conditions stated in

part 2, section 2. An opening of 7.75” x 7.75” should

be provided in the wall for the vent terminal

installation.

2.4.2) Orientation of the flexible

connection

The vent terminal is factory assembled with the vent

pipe and is ready for use if your application calls for

position # 1 or position # 4 as shown on figure 3. If the

position required for the application is position # 1 or #

4, go directly to section 2.4.3 of this chapter. If the

position required for the application is one of # 2, # 3,

# 5 or # 6 you should proceed using the following

instructions.

To meet a Horizontal Side connection for either

combustion air pipe or vent pipe you should

rotate the square tube 90

o

CW or CCW depending

of your needs.

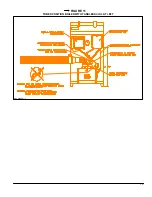

1. Take the outdoor flanged guard off in removing

the 8 stainless steel metal screws as identified “A”

(see figure 4);

2. Take the venturi assembly off in removing the 8

stainless steel metal screws as identified “B” (see

figure 4);

Note:

1- The cone diffuser and vent pipe assembly

stay together during this operation.

2- The slope direction of the outdoor end cone

diffuser should be down when the vent

terminal is installed.

3. Turn the square tubing on is position required;

4. Screw the venturi assembly (see note 2) on the

square tubing;

5. Screw the outdoor flange guard to the square

tubing section of the vent terminal and make sure

that the square opening of the guard is aligned

with the outdoor end cone diffuser.

Summary of Contents for SCS-5-08-3

Page 5: ...6 FIGURE 1 FIGURE 2 DNS 0701 Rév B DNS 0501 Rév D ...

Page 6: ...7 VUE DE CÔTÉ FIGURE 3 DNS 0866 Rév A VUE ARRIÈRE ...

Page 12: ...13 FIGURE 11 POSITIONNEMENT DES TUBES CHAUDIÈRE AVEC SERPENTIN À GAUCHE DNS 0689 Rév C ...

Page 13: ...14 FIGURE 12 POSITIONNEMENT DES TUBES CHAUDIÈRE AVEC SERPENTIN À DROITE DNS 0690 Rév C ...

Page 16: ...17 FIGURE 13 Diagramme électrique DNS 0463 Rév C ...

Page 17: ...18 FIGURE 14 Vérification de la pression totale de fonctionnement DNS 0499 Rév C ...

Page 20: ...21 LISTE DE PIÈCES Modèle SCS 5 DNS 0475 Rév I ...

Page 26: ...6 FIGURE 1 FIGURE 2 DNS 0701 Rev B DNS 0501 Rev D ...

Page 27: ...7 FIGURE 3 SIDE VIEW REAR VIEW DNS 0866 Rev A ...

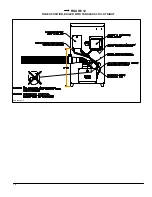

Page 30: ...10 FIGURE 6 5 inches diameter Vent Pipe End Connection FIGURE 7 DNS 0481 Rev B DNS 0867 Rev A ...

Page 33: ...13 FIGURE 11 TUBES POSITION BOILER WITH TANKLESS COIL AT LEFT DNS 0689 Rev C ...

Page 34: ...14 FIGURE 12 TUBES POSITION BOILER WITH TANKLESS COIL AT RIGHT DNS 0690 Rev C ...

Page 37: ...17 FIGURE 13 Electric wiring diagram DNS 0643 Rev C ...

Page 38: ...18 FIGURE 14 Verification of the total operating pressure DNS 0499 Rév C ...