11

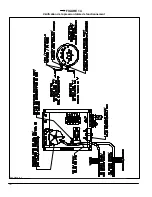

FIGURE 8

2.6)

BURNER

SLEEVE

WITH

PRESSURE

TAP

The SCS system is equipped with a safety control

device. A burner sleeve with pressure tap figure 9 will

be used for the over fire pressure reading. The burner

sleeve should be installed with the pressure tapping

on top as shown on figure 9. The Riello 40-BF5 burner

should be installed on the burner sleeve with insertion

length of 3 ½ inches.

2.7)

CONNECTION TO THE BURNER

COMBUSTION AIR INTAKE

1. Install the 90

o

galvanized elbow supplied with the

kit on the 3 inches diameter burner air intake.

Secure in place with a ¾” long metal screws;

2. Insert the 4 inches combustion air pipe to the 4

inches end of the elbow;

3. Install all around the joint, the extruded grey

gasket;

4. Install the 4 inches collar supply around the

aluminum 4 inches diameter pipe and centered

with the elbow joint;

5. Tighten the collar firmly on the assembly.

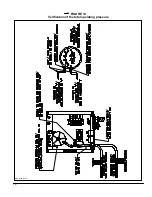

2.8)

ELECTRIC

BOX

CONNECTIONS

1. The electric box supplied with this kit encloses

pressure switch and

should be installed

vertically to

respect the calibration of the

pressure switch;

2. The position for a practical installation and a

proper operation is shown on the figure 11 and on

the figure 12;

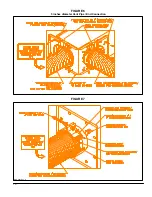

3. Install the ‘’VACUUM’’ silicone hose on the top

right side 5/8” diameter opening of the Riello 40-

BF5 Oil Burner with the compress fitting supplied

with the kit. Refer to the figures 11 and 12 for

correct position of the tubing;

IMPORTANT

1/8 silicone hoses must be install to allow the flow of

the water from control to the burner and the burner

sleeve. They must be cut at the good length, if

necessary.

4. Install the ‘’PRESSURE’’ silicone hose on the

pressure tap fitting of the burner sleeve previously

installed between the burner flange and the boiler.

Refer to the figures 11 and 12 for the correct

position of the tubing;

5. Refer to the electric wiring diagram shown on

figure 13 for electrical connection. The installation

of the equipment should be in accordance with the

regulations of authorities having jurisdiction.

DNS-0868 Rev. A

Summary of Contents for SCS-5-08-3

Page 5: ...6 FIGURE 1 FIGURE 2 DNS 0701 Rév B DNS 0501 Rév D ...

Page 6: ...7 VUE DE CÔTÉ FIGURE 3 DNS 0866 Rév A VUE ARRIÈRE ...

Page 12: ...13 FIGURE 11 POSITIONNEMENT DES TUBES CHAUDIÈRE AVEC SERPENTIN À GAUCHE DNS 0689 Rév C ...

Page 13: ...14 FIGURE 12 POSITIONNEMENT DES TUBES CHAUDIÈRE AVEC SERPENTIN À DROITE DNS 0690 Rév C ...

Page 16: ...17 FIGURE 13 Diagramme électrique DNS 0463 Rév C ...

Page 17: ...18 FIGURE 14 Vérification de la pression totale de fonctionnement DNS 0499 Rév C ...

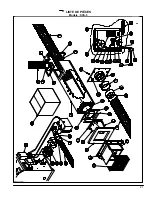

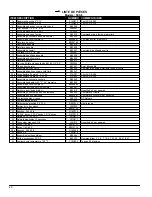

Page 20: ...21 LISTE DE PIÈCES Modèle SCS 5 DNS 0475 Rév I ...

Page 26: ...6 FIGURE 1 FIGURE 2 DNS 0701 Rev B DNS 0501 Rev D ...

Page 27: ...7 FIGURE 3 SIDE VIEW REAR VIEW DNS 0866 Rev A ...

Page 30: ...10 FIGURE 6 5 inches diameter Vent Pipe End Connection FIGURE 7 DNS 0481 Rev B DNS 0867 Rev A ...

Page 33: ...13 FIGURE 11 TUBES POSITION BOILER WITH TANKLESS COIL AT LEFT DNS 0689 Rev C ...

Page 34: ...14 FIGURE 12 TUBES POSITION BOILER WITH TANKLESS COIL AT RIGHT DNS 0690 Rev C ...

Page 37: ...17 FIGURE 13 Electric wiring diagram DNS 0643 Rev C ...

Page 38: ...18 FIGURE 14 Verification of the total operating pressure DNS 0499 Rév C ...