15

PART 3

OPERATION

3.1)

START-UP AND ADJUSTMENTS

For the start-up of your heating unit, please refer to the

instruction manual that came with it. Using a SCS

System is similar to a conventional chimney with the

following particularities.

CAUTION

This procedure should be done only by a

qualified technician.

3.1.1) OIL BURNER SPECIFICATIONS

The SCS system is certified for the RIELLO 40-BF5 oil

burner for an input range of 1.00 to 1.35 USGPH.

Refer to table 2 for operation specifications. For oil

burner servicing refer to the oil burner instruction

manual.

The 40-BF5 Oil Burner used with the SCS

System should never operate without the outdoor

combustion air provision.

3.1.2) Setting the 40-BF5 burner air

damper adjustment

Note:

Variations in flue gas smoke and CO

2

readings

will occur with the burner cover in place or not

in place. Therefore, the burner cover must be

in place when making the final combustion

instrument readings to ensure proper test

results.

The 40-BF5 air shutter adjustments can be made with

the burner cover in place by :

1. Removing the plastic plug on the top of the

burner cover;

2. Using a Phillips screwdriver you could reach the

air shutter adjustment screw;

3. Turning the screw clockwise ( + indicator) to

increase combustion air;

4. Turning the screw anti-clockwise( - indicator) to

decrease combustion air;

5. Installing back the plastic plug when the air

shutter adjustment is completed.

3.1.3) Perform the smoke and CO

2

test

1. Start the appliance and from the test port

provided on the BREECH PLATE of the boiler,

proceed with smoke test and adjust the burner to

get between #1 and a "trace" of smoke rating

after at least 5 to 10 minutes of operation and

also with a minimum of 140

o

F (60

o

C) water

temperature;

2. Measure the CO

2

(or O

2

) and note it. This is the

vital reference point for further adjustments;

Example : 13.5 % CO

2

(or 2.6 % O

2

)

3. Open the burner air damper to get 0.5 to 1.5%

CO

2

less than the previous reading (0.7 to 2.0 %

of O

2

more then the previous reading);

Example : Reduce CO

2

from 13.5 to 12.5 % (or

increase O

2

from 2.6 to 4.2 %)

4. Take a smoke test in this condition. The new

smoke reading should give you between a "trace"

and #0.

TABLE 2

Capacity

Input

Burner

Nozzle

*Turbulator

*Air

Pump Press.

(BTU / H)

(USGPH)

Model

Delavan

Danfoss

Setting

Band

(PSI)

118 000

1.00

Riello 40-BF5

0.85-80B

0.85-80AS

1

4

140

141 000

1.2

Riello 40-BF5

1.10-80B

1.10-80AS

1

6

120

158 000

1.35

Riello 40-BF5

1.10-80B

1.10-80AS

2

4

150

* Air adjustment setting with the burner cover installed. Can change from one unit to another.

Summary of Contents for SCS-5-08-3

Page 5: ...6 FIGURE 1 FIGURE 2 DNS 0701 Rév B DNS 0501 Rév D ...

Page 6: ...7 VUE DE CÔTÉ FIGURE 3 DNS 0866 Rév A VUE ARRIÈRE ...

Page 12: ...13 FIGURE 11 POSITIONNEMENT DES TUBES CHAUDIÈRE AVEC SERPENTIN À GAUCHE DNS 0689 Rév C ...

Page 13: ...14 FIGURE 12 POSITIONNEMENT DES TUBES CHAUDIÈRE AVEC SERPENTIN À DROITE DNS 0690 Rév C ...

Page 16: ...17 FIGURE 13 Diagramme électrique DNS 0463 Rév C ...

Page 17: ...18 FIGURE 14 Vérification de la pression totale de fonctionnement DNS 0499 Rév C ...

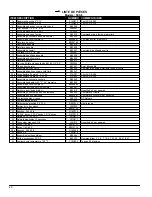

Page 20: ...21 LISTE DE PIÈCES Modèle SCS 5 DNS 0475 Rév I ...

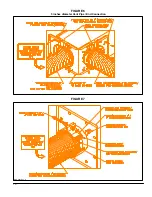

Page 26: ...6 FIGURE 1 FIGURE 2 DNS 0701 Rev B DNS 0501 Rev D ...

Page 27: ...7 FIGURE 3 SIDE VIEW REAR VIEW DNS 0866 Rev A ...

Page 30: ...10 FIGURE 6 5 inches diameter Vent Pipe End Connection FIGURE 7 DNS 0481 Rev B DNS 0867 Rev A ...

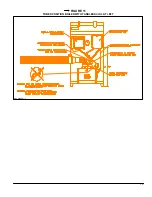

Page 33: ...13 FIGURE 11 TUBES POSITION BOILER WITH TANKLESS COIL AT LEFT DNS 0689 Rev C ...

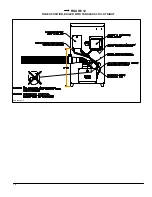

Page 34: ...14 FIGURE 12 TUBES POSITION BOILER WITH TANKLESS COIL AT RIGHT DNS 0690 Rev C ...

Page 37: ...17 FIGURE 13 Electric wiring diagram DNS 0643 Rev C ...

Page 38: ...18 FIGURE 14 Verification of the total operating pressure DNS 0499 Rév C ...