Maintenance

Section

4-18

AB38 Work Platform

CHANGING THE OIL

Unless an oil suction system can be used, it is

necessary to remove the gearbox to fully drain the oil.

1.

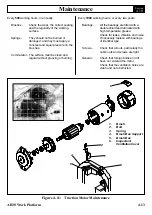

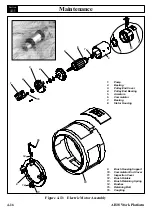

The AB38 should be driven for five minutes in

order to bring the oil up to working temperature.

2.

The Electric Traction Motor must be

disconnected from the Gearbox.

Disconnect the batteries when working near

the traction motors.

3.

Unscrew the four bolts that hold the traction

motor to the Gearbox and pull the Motor away

from the rear face of the Gearbox.

4.

Disconnect the brake hose from the brake port

on the Gearbox and plug to avoid excessive oil

spillage.

5.

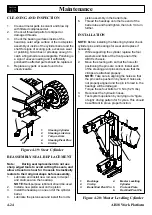

Loosen the five wheel nuts securing the Wheel

Assembly to the Gearbox studs.

6.

Jack up the rear of the AB38 and chock the

front wheels to prevent the machine from

moving during the service.

7.

Remove the Wheel Assembly by unscrewing

the five wheel nuts

8.

Unscrew the eight securing bolts that hold the

Gearbox to the Chassis, and remove the

Gearbox, noting its orientation on the chassis

before removal.

9.

Remove the oil filler and drain plugs from the

front (stud) face of the Gearbox.

10.

Stand the Gearbox vertically (studs facing

down) in a suitable oil disposal container and

allow the oil to drain fully.

11.

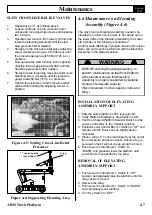

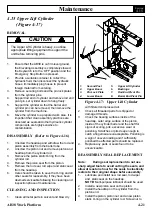

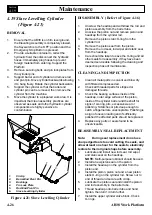

The Gearbox needs to be half filled which

requires approximately 0.9 Litres (0.23 Gallons

US) of oil. To check this level, rotate the

Gearbox into the horizontal position with one of

the filler/drain plug holes in the 3 O’ Clock

position and the other plug hole above it (See

fig 4-14 ). When the Gearbox is half full oil will

just start to trickle out the plug hole in the 3

O’Clock position.

12.

Insert and tighten both plugs and clean the

surfaces of the gearbox.

13.

Reattach the Gearbox to the Chassis in its

original position with the eight securing bolts.

The Gearbox Securing Bolts must be torqued

to 130 Nm (96 ft. lbs).

WARNING

14.

Reattach the brake hose to the brake port.

15.

Reattach the Wheel Assembly to the Gearbox

using the five M14 nuts.

The Wheel Assembly Nuts must be torqued

as per values given in Table 4-1.

16.

Reattach the Electric Traction Motor to the

Gearbox.

The Electric Traction Motor Bolts must be

torqued to 74 Nm (55 ft. lbs).

Repeat this procedure for the other Drive

Gearbox.

CAUTION

CAUTION

CAUTION

4.13

4.13

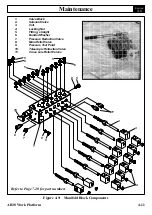

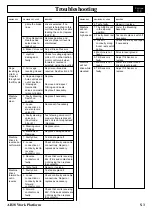

Torque Specifications

RETAINING BOLTS

Use the following values to torque bolts used on

Ui

AB38 Work Platform unless a specific torque value is

called out for the part being installed.

Table 4-3: Bolt Torques

Torque

Thread Size

Location

Metric

Imperial

M4

SPIRIT

3 Nm

2 Ft/Lbs

LEVEL

M6

VARIOUS

10 Nm

7 Ft/Lbs

M8

TRUNNION

25 Nm

18 Ft/Lbs

M10

PIN LOCK

45 Nm

33 Ft/Lbs

PLATES

M12

TORQUE

90 Nm

67 Ft/Lbs

ARMS

5/8” -11 UNC

SLEW

220 Nm

165 Ft/Lbs

x 3 1/2”

BEARING

(ISO 10.9)

(US Grade 8)

NOTE:

All Bolts are ISO Grade 8.8 unless

otherwise stated

Summary of Contents for AB38

Page 2: ...ii AB38 Work Platform NOTES...

Page 4: ...ii AB38 Work Platform NOTES...

Page 6: ...iv AB38 Work Platform NOTES Foreword...

Page 10: ...Contents Section IV AB38 Work Platform i NOTES...

Page 14: ...Introduction Specifications Section 1 4 AB38 Work Platform NOTES 1 3...

Page 17: ...Machine Preparation Section 2 3 AB38 Work Platform NOTES 2 7...

Page 18: ...Machine Preparation Section 2 4 AB38 Work Platform 2 7 NOTES...

Page 29: ...Operation Section 3 11 AB38 Work Platform NOTES 3 5...

Page 30: ...Operation Section 3 12 AB38 Work Platform NOTES 3 5...

Page 59: ...Maintenance Section 4 29 AB38 Work Platform NOTES 4 21...

Page 60: ...Maintenance Section 4 30 AB38 Work Platform NOTES 4 21...

Page 66: ...Troubleshooting Section 5 6 AB38 Work Platform 5 7 NOTES...

Page 68: ...Schematics Section 6 2 AB38 Work Platform NOTES 6 0...

Page 72: ...Schematics Section 6 6 AB38 Work Platform 6 1 NOTES...

Page 73: ...Electrical Schematic Schematics 6 7 AB38 Work Platform Section 6 1...

Page 74: ...Electrical Schematic Schematics 6 8 AB38 Work Platform Section 6 1 TOP VIEW...

Page 76: ...Schematics Section 6 10 AB38 Work Platform NOTES 6 2...

Page 78: ...Section 6 2 6 12 AB38 Work Platform Schematics NOTES...

Page 81: ...Illustrated Parts Breakdown Section 7 3 AB38 Work Platform 7 2...

Page 83: ...Illustrated Parts Breakdown Section 7 5 AB38 Work Platform 7 2...

Page 85: ...Illustrated Parts Breakdown Section 7 7 AB38 Work Platform 7 2...

Page 87: ...Illustrated Parts Breakdown Section 7 9 AB38 Work Platform 7 2...

Page 89: ...Illustrated Parts Breakdown Section 7 11 AB38 Work Platform 7 2 22...

Page 91: ...Illustrated Parts Breakdown Section 7 13 AB38 Work Platform 7 2...

Page 93: ...Illustrated Parts Breakdown Section 7 15 AB38 Work Platform 7 2...

Page 95: ...Illustrated Parts Breakdown Section 7 17 AB38 Work Platform 7 2...

Page 97: ...Illustrated Parts Breakdown Section 7 19 AB38 Work Platform 7 2...

Page 99: ...Illustrated Parts Breakdown Section 7 21 AB38 Work Platform 7 2...

Page 101: ...Illustrated Parts Breakdown Section 7 23 AB38 Work Platform 7 2...

Page 103: ...Illustrated Parts Breakdown Section 7 25 AB38 Work Platform 7 2...

Page 105: ...Illustrated Parts Breakdown Section 7 27 AB38 Work Platform 7 2...

Page 107: ...Illustrated Parts Breakdown Section 7 29 AB38 Work Platform 7 2...

Page 109: ...Illustrated Parts Breakdown Section 7 31 AB38 Work Platform 7 2...

Page 111: ...Illustrated Parts Breakdown Section 7 33 AB38 Work Platform 7 2...

Page 113: ...Illustrated Parts Breakdown Section 7 35 AB38 Work Platform 7 2...

Page 115: ...Illustrated Parts Breakdown Section 7 37 AB38 Work Platform 7 2...

Page 117: ...Illustrated Parts Breakdown Section 7 39 AB38 Work Platform 7 2...

Page 119: ...Illustrated Parts Breakdown Section 7 41 AB38 Work Platform 7 2 8 9...

Page 121: ...Illustrated Parts Breakdown Section 7 43 AB38 Work Platform 7 2...

Page 123: ...Illustrated Parts Breakdown Section 7 45 AB38 Work Platform 7 2...

Page 125: ...Illustrated Parts Breakdown Section 7 47 AB38 Work Platform 7 2...

Page 127: ...Illustrated Parts Breakdown Section 7 49 AB38 Work Platform 7 2...

Page 131: ...Illustrated Parts Breakdown Section 7 53 AB38 Work Platform 7 2 NOTES...

Page 133: ...Technician s Print AB38 Work Platform Electrical Schematic...