Maintenance

Section

4-14

AB38 Work Platform

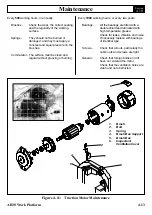

4.11 Electric Motor (Figure 4-13)

Before carrying out any maintenance

procedures on the electric motor ensure that

the electric circuit is disconnected i.e.

disconnect the batteries and unplug the

charger. It is also important that when dealing

with batteries the proper safety precautions

are adhered to. There is always a hazard of

sparks or explosive gas.

TROUBLESHOOTING

1.

Read the nameplate to become familiar with the

motor, especially the rated voltage.

2.

Try to turn the shaft by hand. Keep motor leads

separated while doing this.

If the shaft turns

freely go to step 3. If the shaft won’t turn,

proceed to step 2A.

2A.

The shaft could be tight for a number of

reasons , this check is to determine if the

tightness is of a temporary nature only. Obtain

power to produce the nameplate voltage. Do

not make a permanent connection.

First touch the motor leads quickly to the power

supply just long enough to observe if the shaft

runs. If it does turn, then hold the motor leads

on the power supply for a longer time. If the

motor sounds normal , go to step 3.

If the motor is noisy it should be taken apart as

described in the

DISASSEMBLY

section.

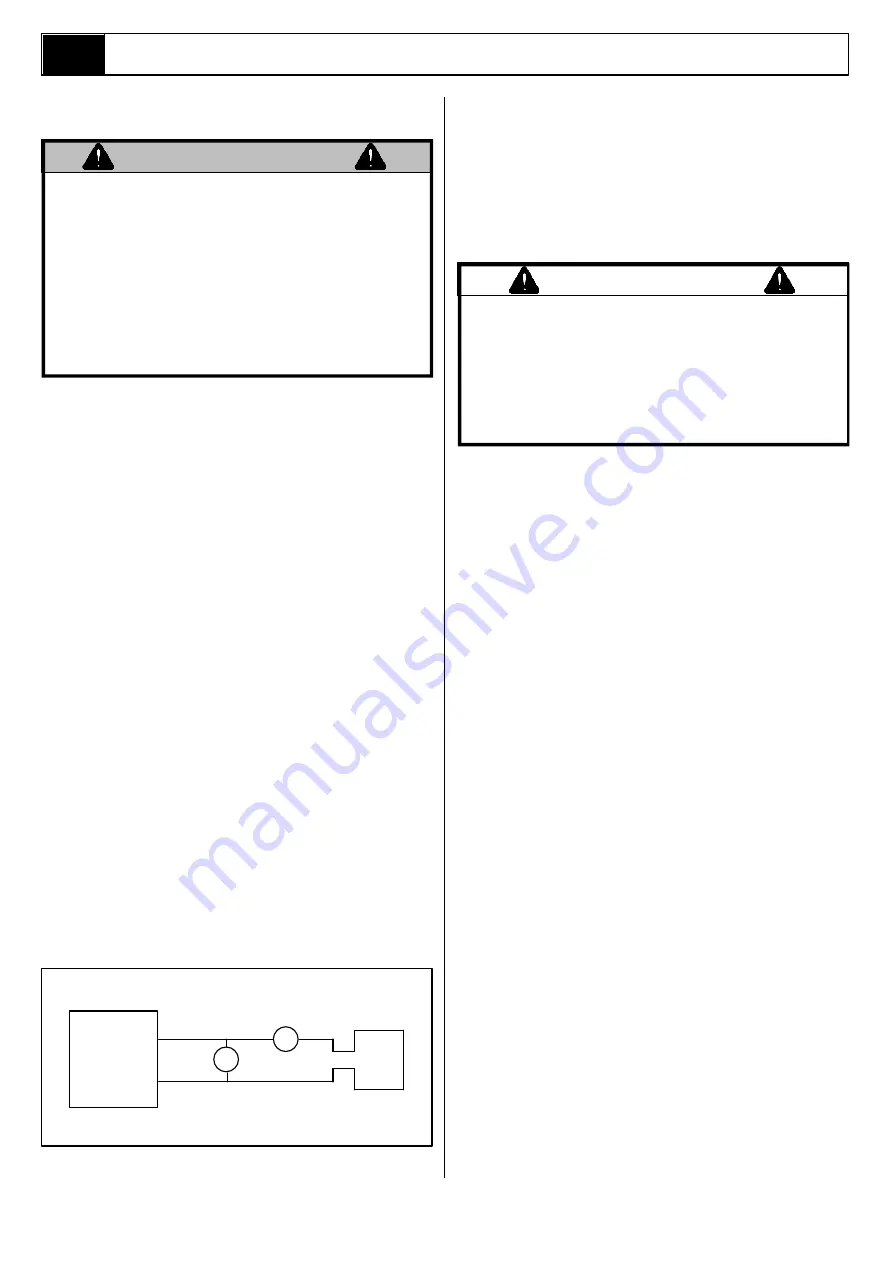

3.

If the motor turned freely, connect an ammeter

in the circuit as shown in Figure 4-12. With

rated voltage applied and the shaft running free,

the ammeter should read less than 20% of the

nameplate full load current. If the motor meets

the above conditions then it can be assumed

that the original problem is external to the

motor.

WARNING

DISASSEMBLY

1.

Remove through bolts.

2.

Remove pulley end cover

3.

Pull the armature out of the assembly in one

swift motion.

4.

Remove commutator end cover.

NOTE:

Do not place the stator ring in any

mechanical holding device during the

disassembly or assembly operation.

Permanent distortion or other damage will

result.

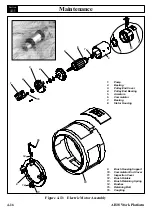

INSPECTION

Once the motor has been disassembled, go through

the following check list steps to determine where the

problem lies.

1.

Bearings should spin smoothly and easily and

have ample lubrication and be free of corrosion.

2.

Armature should be checked for grounds and

shorted Windings. Refinish commutator

surface if pitted or excessively worn.

3.

Brushes should be checked for wear and to

ensure that they are free in the brush holders.

NOTE:

Observe how the brushes are

assembled in brush holders and position of

brush lead. New brushes must be installed in

same manner. Brushes should be removed as

follows:

• Remove brush spring clip from its

mounting on brush assembly.

• Lift brush assembly from the brush holder

• Disconnect brush assembly lead.

• New brush assembly to be installed by

reversing the above procedure.

4.

Inspect wire harness and all connections for

signs of damage due to overheating.

5.

Check stator to see if it is securely mounted.

CAUTION

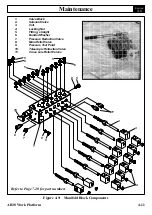

REASSEMBLY

1.

Install new brushes and be sure they are free in

the holder. Install brush with the lead wires

positioned as when received.

2.

Place commutator cover on a work bench with

brush assembly facing upward.

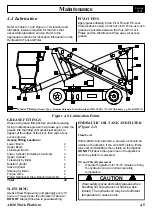

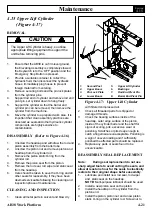

Figure 4-12: Electrical Test Circuit

4.11

AMP METER

A

V

VOLTMETER

D.C.

Power

Supply

D.C.

Motor

Summary of Contents for AB38

Page 2: ...ii AB38 Work Platform NOTES...

Page 4: ...ii AB38 Work Platform NOTES...

Page 6: ...iv AB38 Work Platform NOTES Foreword...

Page 10: ...Contents Section IV AB38 Work Platform i NOTES...

Page 14: ...Introduction Specifications Section 1 4 AB38 Work Platform NOTES 1 3...

Page 17: ...Machine Preparation Section 2 3 AB38 Work Platform NOTES 2 7...

Page 18: ...Machine Preparation Section 2 4 AB38 Work Platform 2 7 NOTES...

Page 29: ...Operation Section 3 11 AB38 Work Platform NOTES 3 5...

Page 30: ...Operation Section 3 12 AB38 Work Platform NOTES 3 5...

Page 59: ...Maintenance Section 4 29 AB38 Work Platform NOTES 4 21...

Page 60: ...Maintenance Section 4 30 AB38 Work Platform NOTES 4 21...

Page 66: ...Troubleshooting Section 5 6 AB38 Work Platform 5 7 NOTES...

Page 68: ...Schematics Section 6 2 AB38 Work Platform NOTES 6 0...

Page 72: ...Schematics Section 6 6 AB38 Work Platform 6 1 NOTES...

Page 73: ...Electrical Schematic Schematics 6 7 AB38 Work Platform Section 6 1...

Page 74: ...Electrical Schematic Schematics 6 8 AB38 Work Platform Section 6 1 TOP VIEW...

Page 76: ...Schematics Section 6 10 AB38 Work Platform NOTES 6 2...

Page 78: ...Section 6 2 6 12 AB38 Work Platform Schematics NOTES...

Page 81: ...Illustrated Parts Breakdown Section 7 3 AB38 Work Platform 7 2...

Page 83: ...Illustrated Parts Breakdown Section 7 5 AB38 Work Platform 7 2...

Page 85: ...Illustrated Parts Breakdown Section 7 7 AB38 Work Platform 7 2...

Page 87: ...Illustrated Parts Breakdown Section 7 9 AB38 Work Platform 7 2...

Page 89: ...Illustrated Parts Breakdown Section 7 11 AB38 Work Platform 7 2 22...

Page 91: ...Illustrated Parts Breakdown Section 7 13 AB38 Work Platform 7 2...

Page 93: ...Illustrated Parts Breakdown Section 7 15 AB38 Work Platform 7 2...

Page 95: ...Illustrated Parts Breakdown Section 7 17 AB38 Work Platform 7 2...

Page 97: ...Illustrated Parts Breakdown Section 7 19 AB38 Work Platform 7 2...

Page 99: ...Illustrated Parts Breakdown Section 7 21 AB38 Work Platform 7 2...

Page 101: ...Illustrated Parts Breakdown Section 7 23 AB38 Work Platform 7 2...

Page 103: ...Illustrated Parts Breakdown Section 7 25 AB38 Work Platform 7 2...

Page 105: ...Illustrated Parts Breakdown Section 7 27 AB38 Work Platform 7 2...

Page 107: ...Illustrated Parts Breakdown Section 7 29 AB38 Work Platform 7 2...

Page 109: ...Illustrated Parts Breakdown Section 7 31 AB38 Work Platform 7 2...

Page 111: ...Illustrated Parts Breakdown Section 7 33 AB38 Work Platform 7 2...

Page 113: ...Illustrated Parts Breakdown Section 7 35 AB38 Work Platform 7 2...

Page 115: ...Illustrated Parts Breakdown Section 7 37 AB38 Work Platform 7 2...

Page 117: ...Illustrated Parts Breakdown Section 7 39 AB38 Work Platform 7 2...

Page 119: ...Illustrated Parts Breakdown Section 7 41 AB38 Work Platform 7 2 8 9...

Page 121: ...Illustrated Parts Breakdown Section 7 43 AB38 Work Platform 7 2...

Page 123: ...Illustrated Parts Breakdown Section 7 45 AB38 Work Platform 7 2...

Page 125: ...Illustrated Parts Breakdown Section 7 47 AB38 Work Platform 7 2...

Page 127: ...Illustrated Parts Breakdown Section 7 49 AB38 Work Platform 7 2...

Page 131: ...Illustrated Parts Breakdown Section 7 53 AB38 Work Platform 7 2 NOTES...

Page 133: ...Technician s Print AB38 Work Platform Electrical Schematic...