Maintenance

Section

4-15

AB38 Work Platform

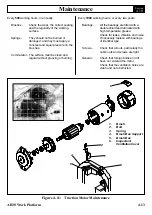

3.

Place the bearing spring into the bearing bore.

4.

Take a complete armature assembly, including

bearings, and insert commutator end bearing

into the bearing bore.

Note:

Do not reuse bearings which have been

removed from armature shaft. Keep assembly

in a vertical position. Use extreme care not to

damage armature with bearing pullers. New

bearings should be installed by pressing inner

race of bearing onto proper position on

armature shaft.

5.

Set the brushes to final position and lock with

springs.

6.

Place the complete stator down over the

vertical armature, and into position on the

commutator cover.

7.

The stator assembly must be placed in a

definite relationship with the commutator covers

in order to obtain a neutral brush setting. There

is a match-mark on both items. These two

marks must line up exactly.

Rotate until they do.

8.

Assemble the pulley end cover in the proper

relationship. Insert mounting bolts and tighten

alternately to ensure a good mechanical

alignment.

9.

Spin the shaft by hand to see if it is free. Be

sure motor leads (if used) are not touching

together. If the leads are touching, a generator

action will give the effect of friction in the motor.

A no-load test can now be performed. At rated

voltage, observe the no-load current. It should

be less than 20% of the nameplate full load

current. Anything higher will indicate:

• Brushes are not on neutral setting

(check matchmarks for exact alignment)

• Faulty armature.

NOTE:

Following assembly, the electric motor

may turn in the wrong direction. The cause

of this will be that the brush holder assembly

has been connected the wrong way. To solve

this disassemble and reconnect in the

proper way. Reversing the polarity will not

solve this problem as this is a series wound

motor.

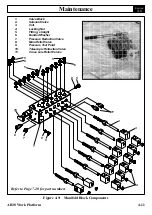

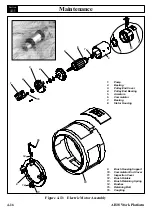

MAINTENANCE INTERVALS &

PROCEDURES

Every

500

working hours, or annually

Brushes -

Check the wear, the correct seating,

and the regularity of the working

surface.

Springs -

They should not be burned or

damaged, and they must apply a

constant and equal pressure on the

brushes.

Commutator - The surface must be clean and

regular without grooving or burning.

Every

1000

working hours, every two years

Bearings-

All the bearings are fitted with a

double shield and lubricated with

high temperature grease.

Check for leaks, vibration and noise.

If necessary replace with bearings

of Identical type.

Seals -

Check that hydraulic seals are in

perfect condition.

Screws -

Check that all nuts, particularly the

cable nuts and screws are tight.

General -

Check that foreign bodies or dirt

have not entered the motor.

Check that the ventilation holes are

clean and not obstructed.

4.11

Summary of Contents for AB38

Page 2: ...ii AB38 Work Platform NOTES...

Page 4: ...ii AB38 Work Platform NOTES...

Page 6: ...iv AB38 Work Platform NOTES Foreword...

Page 10: ...Contents Section IV AB38 Work Platform i NOTES...

Page 14: ...Introduction Specifications Section 1 4 AB38 Work Platform NOTES 1 3...

Page 17: ...Machine Preparation Section 2 3 AB38 Work Platform NOTES 2 7...

Page 18: ...Machine Preparation Section 2 4 AB38 Work Platform 2 7 NOTES...

Page 29: ...Operation Section 3 11 AB38 Work Platform NOTES 3 5...

Page 30: ...Operation Section 3 12 AB38 Work Platform NOTES 3 5...

Page 59: ...Maintenance Section 4 29 AB38 Work Platform NOTES 4 21...

Page 60: ...Maintenance Section 4 30 AB38 Work Platform NOTES 4 21...

Page 66: ...Troubleshooting Section 5 6 AB38 Work Platform 5 7 NOTES...

Page 68: ...Schematics Section 6 2 AB38 Work Platform NOTES 6 0...

Page 72: ...Schematics Section 6 6 AB38 Work Platform 6 1 NOTES...

Page 73: ...Electrical Schematic Schematics 6 7 AB38 Work Platform Section 6 1...

Page 74: ...Electrical Schematic Schematics 6 8 AB38 Work Platform Section 6 1 TOP VIEW...

Page 76: ...Schematics Section 6 10 AB38 Work Platform NOTES 6 2...

Page 78: ...Section 6 2 6 12 AB38 Work Platform Schematics NOTES...

Page 81: ...Illustrated Parts Breakdown Section 7 3 AB38 Work Platform 7 2...

Page 83: ...Illustrated Parts Breakdown Section 7 5 AB38 Work Platform 7 2...

Page 85: ...Illustrated Parts Breakdown Section 7 7 AB38 Work Platform 7 2...

Page 87: ...Illustrated Parts Breakdown Section 7 9 AB38 Work Platform 7 2...

Page 89: ...Illustrated Parts Breakdown Section 7 11 AB38 Work Platform 7 2 22...

Page 91: ...Illustrated Parts Breakdown Section 7 13 AB38 Work Platform 7 2...

Page 93: ...Illustrated Parts Breakdown Section 7 15 AB38 Work Platform 7 2...

Page 95: ...Illustrated Parts Breakdown Section 7 17 AB38 Work Platform 7 2...

Page 97: ...Illustrated Parts Breakdown Section 7 19 AB38 Work Platform 7 2...

Page 99: ...Illustrated Parts Breakdown Section 7 21 AB38 Work Platform 7 2...

Page 101: ...Illustrated Parts Breakdown Section 7 23 AB38 Work Platform 7 2...

Page 103: ...Illustrated Parts Breakdown Section 7 25 AB38 Work Platform 7 2...

Page 105: ...Illustrated Parts Breakdown Section 7 27 AB38 Work Platform 7 2...

Page 107: ...Illustrated Parts Breakdown Section 7 29 AB38 Work Platform 7 2...

Page 109: ...Illustrated Parts Breakdown Section 7 31 AB38 Work Platform 7 2...

Page 111: ...Illustrated Parts Breakdown Section 7 33 AB38 Work Platform 7 2...

Page 113: ...Illustrated Parts Breakdown Section 7 35 AB38 Work Platform 7 2...

Page 115: ...Illustrated Parts Breakdown Section 7 37 AB38 Work Platform 7 2...

Page 117: ...Illustrated Parts Breakdown Section 7 39 AB38 Work Platform 7 2...

Page 119: ...Illustrated Parts Breakdown Section 7 41 AB38 Work Platform 7 2 8 9...

Page 121: ...Illustrated Parts Breakdown Section 7 43 AB38 Work Platform 7 2...

Page 123: ...Illustrated Parts Breakdown Section 7 45 AB38 Work Platform 7 2...

Page 125: ...Illustrated Parts Breakdown Section 7 47 AB38 Work Platform 7 2...

Page 127: ...Illustrated Parts Breakdown Section 7 49 AB38 Work Platform 7 2...

Page 131: ...Illustrated Parts Breakdown Section 7 53 AB38 Work Platform 7 2 NOTES...

Page 133: ...Technician s Print AB38 Work Platform Electrical Schematic...