77

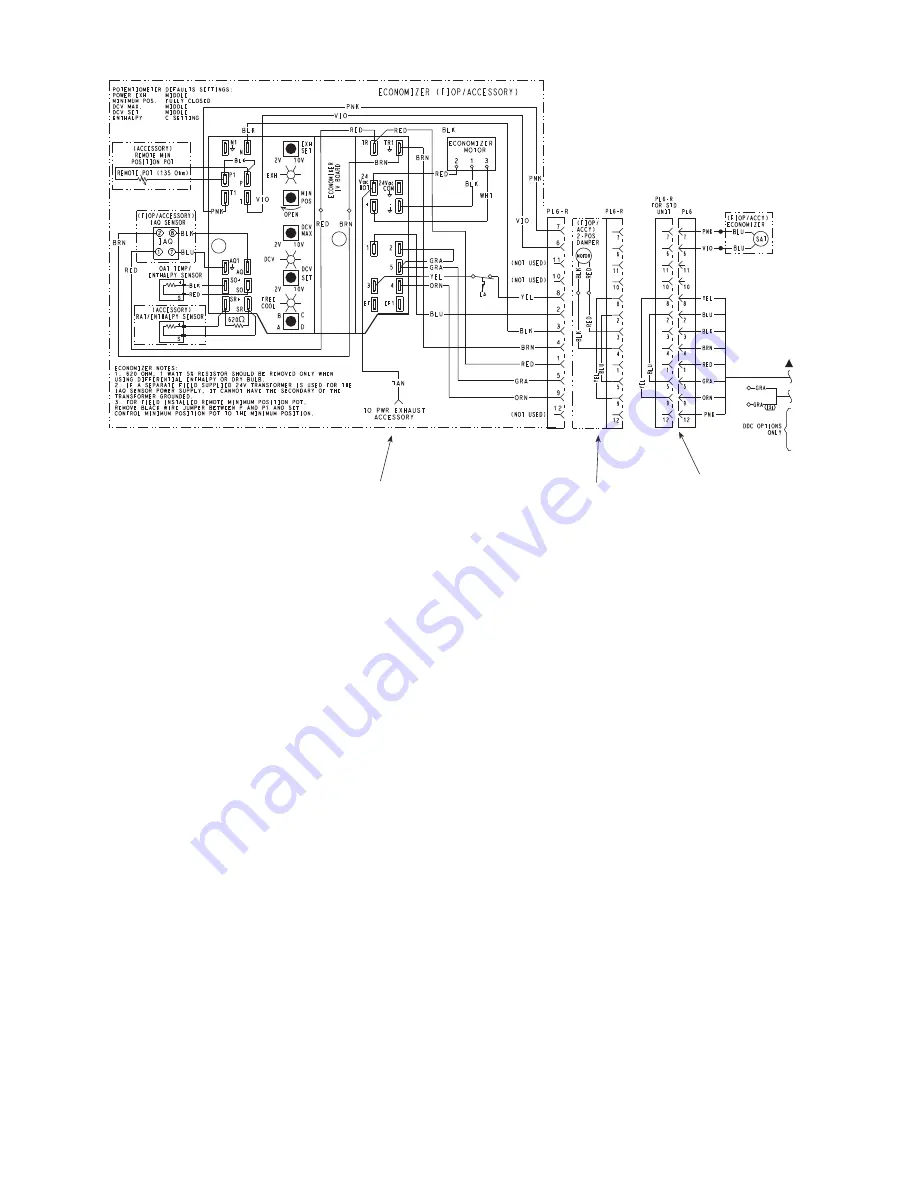

Fig. 129 — EconoMi$er

®

IV Wiring

Step 11 — Adjust Factory-Installed Options

SMOKE DETECTORS — Smoke detector(s) will be con-

nected at the Controls Connections Board, at terminals marked

“Smoke Shutdown.” Cut jumper JMP 3 when ready to ener-

gize unit.

ECONOMI$ER IV OCCUPANCY SWITCH — Refer to

Fig. 129 for general EconoMi$er IV wiring. External occupan-

cy control is managed through a connection on the Controls

Connections Board.

If external occupancy control is desired, connect a time

clock or remotely controlled switch (closed for Occupied, open

for Unoccupied sequence) at terminals marked OCCUPANCY.

Cut jumper JMP 2 to complete the installation.

Step 12 — Install Accessories —

Available acces-

sories include:

• Roof Curb

• Thru-base connection kit (must be installed before unit is

set on curb)

• Manual outside air damper

• Two-Position motorized outside air damper

• EconoMi$er IV (with control and integrated barometric

relief)

• EconoMi$er2 (without control/for external signal and

integrated barometric relief)

• Power Exhaust

• Differential dry-bulb sensor (EconoMi$er IV)

• Outdoor enthalpy sensor

• Differential enthalpy sensor

• Electric Heaters

• Single point kits

• Low Ambient Controls

• Thermostat / Sensors

• CO

2

sensor

• DDC interface (PremierLink controller)

• Louvered hail guard

• Phase monitor control

Refer to separate installation instructions for information on

installing these accessories.

Step 13 — Check Belt Tension —

Measure the belt

span length as shown in Fig. 130. Calculate the required deflec-

tion by multiplying the belt span length by

1

/

64

. For example, if

the belt span length is 32 inches: 32 x

1

/

64

=

1

/

2

inch deflection.

BELT FORCE — DEFLECTION METHOD — Check the

belt tension with a spring-force belt force deflection gauge

(available from drive belt manufacturer).

1. Place a straightedge along the belt between the two

pulleys. Measure the distance between the motor shaft

and the blower shaft.

2. Set the tension gauge to the desired tension (see Table 1

in Fig. 130). Place the large O-ring at that point.

3. Press the tension checker downward on the belt until the

large O-ring is at the bottom of the straightedge.

4. Adjust the belt tension as needed.

Adjust belt tension by loosing the motor mounting plate

front bolts and rear bolt (see Fig. 131) and slide the plate to-

wards the fan (to reduce tension) or away from the fan (to in-

crease tension). Ensure the blower shaft and motor shaft are

parallel to each other (pulleys aligned). Tighten all bolts se-

curely when finished.

Economizer

2 Position Damper

Unit Without Economizer or

2 Position Damper

Summary of Contents for Carrier WeatherMaker 50TC A08 Series

Page 4: ...4 Fig 2 Unit Dimensional Drawing Size 08 09 12 Units...

Page 5: ...5 Fig 2 Unit Dimensional Drawing Size 08 09 12 Units cont...

Page 6: ...6 Fig 3 Unit Dimensional Drawing Size 14 Unit...

Page 7: ...7 Fig 3 Unit Dimensional Drawing Size 14 Unit cont...

Page 9: ...9 Fig 4 Unit Dimensional Drawing Size 16 Unit cont...

Page 13: ...13 Fig 8 Roof Curb Details Size 16 Unit...

Page 50: ...50 Fig 73 50TC 16 Control Box Component PremierLink Locations...

Page 51: ...51 Fig 74 Typical PremierLink Control Wiring Diagram...

Page 52: ...52 Fig 75 Typical PremierLink Control Wiring Diagram with Humidi MiZer System Option...

Page 64: ...64 Fig 106 Typical RTU Open Controller Wiring Diagram 50TC 08 14 Size Units...

Page 65: ...65 Fig 107 Typical RTU Open Controller Wiring Diagram 50TC 16 Size Unit...