14

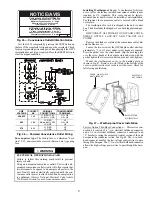

ALTERNATE UNIT SUPPORT (IN LIEU OF CURB OR

SLAB MOUNT) — A non-combustible sleeper rail can be

used in the unit curb support area. If sleeper rails cannot be

used, support the long sides of the unit with a minimum of 3

equally spaced 4-in. x 4-in. (102 mm x 102 mm) pads on each

side.

Step 5 — Field Fabricate Ductwork —

Cabinet

return-air static pressure (a negative condition) shall not exceed

0.35 in. wg (87 Pa) with economizer or 0.45 in. wg (112 Pa)

without economizer.

For vertical ducted applications, secure all ducts to roof curb

and building structure.

Do not connect ductwork to unit.

Fabricate supply ductwork so that the cross sectional di-

mensions are equal to or greater than the unit supply duct open-

ing dimensions for the first 18 in. (458 mm) of duct length

from the unit basepan.

Insulate and weatherproof all external ductwork, joints, and

roof openings with counter flashing and mastic in accordance

with applicable codes.

Ducts passing through unconditioned spaces must be insu-

lated and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return

should be ducted through the roof deck to comply with applica-

ble fire codes.

FOR UNITS WITH ACCESSORY ELECTRIC HEAT-

ERS — All installations require a minimum clearance to com-

bustible surfaces of 1-in. (25 mm) from duct for first 12-in.

(305 mm) away from unit.

Outlet grilles must not lie directly below unit discharge.

NOTE: A 90-degree elbow must be provided in the ductwork

to comply with UL (Underwriters Laboratories) code for use

with electric heat.

Before setting the unit onto the curb, recheck gasketing on

the curb.

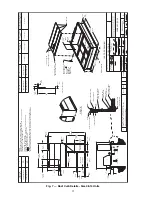

Fig. 9 — Rigging Details

CAUTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in damage to roof-

ing materials.

Membrane roofs can be cut by sharp sheet metal edges. Be

careful when placing any sheet metal parts on such roof.

CAUTION

PERSONAL INJURY HAZARD

Failure to follow this warning could cause personal injury.

For vertical supply and return units, tools or parts could

drop into ductwork and cause an injury. Install a 90-degree

turn in the return ductwork between the unit and the condi-

tioned space. If a 90-degree elbow cannot be installed, then

a grille of sufficient strength and density should be installed

to prevent objects from falling into the conditioned space.

Due to electric heater, supply duct will require 90-degree

elbow.

NOTES:

1. SPREADER BARS REQUIRED — Top damage will occur if spreader bars are not used.

2. Dimensions in ( ) are in millimeters.

3. Hook rigging shackles through holes in base rail, as shown in detail “A.” Holes in base rails are centered around the unit center of gravity.

Use wooden top to prevent rigging straps from damaging unit.

UNIT

MAX WEIGHT

DIMENSIONS

A

B

C

lb

kg

in.

mm

in.

mm

in.

mm

50TC-A08

1290

586

88.0

2235

40.0

1015

41,5

1055

50TC-A09

1410

641

88.0

2235

39.5

1005

49.5

1255

50TC-A12

1515

689

88.0

2235

41,0

1040

49,5

1255

50TC-D/E08

1410

641

88,0

2235

41.0

1040

41.5

1055

50TC-D/E09

1525

693

88.0

2235

40.5

1030

49,5

1255

50TC-D/E12

1565

711

88,0

2235

40,0

1015

49,5

1255

50TC-D/E14

1720

782

88.0

2235

28,5

725

53,0

1345

50TC-D16

912

2010

2945

116.0

1461

57.5

1510

59.5

Summary of Contents for Carrier WeatherMaker 50TC A08 Series

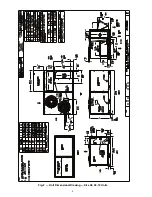

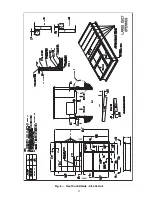

Page 4: ...4 Fig 2 Unit Dimensional Drawing Size 08 09 12 Units...

Page 5: ...5 Fig 2 Unit Dimensional Drawing Size 08 09 12 Units cont...

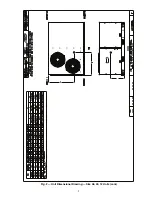

Page 6: ...6 Fig 3 Unit Dimensional Drawing Size 14 Unit...

Page 7: ...7 Fig 3 Unit Dimensional Drawing Size 14 Unit cont...

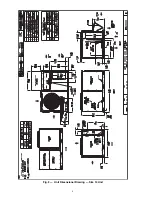

Page 9: ...9 Fig 4 Unit Dimensional Drawing Size 16 Unit cont...

Page 13: ...13 Fig 8 Roof Curb Details Size 16 Unit...

Page 50: ...50 Fig 73 50TC 16 Control Box Component PremierLink Locations...

Page 51: ...51 Fig 74 Typical PremierLink Control Wiring Diagram...

Page 52: ...52 Fig 75 Typical PremierLink Control Wiring Diagram with Humidi MiZer System Option...

Page 64: ...64 Fig 106 Typical RTU Open Controller Wiring Diagram 50TC 08 14 Size Units...

Page 65: ...65 Fig 107 Typical RTU Open Controller Wiring Diagram 50TC 16 Size Unit...