70

mounting the sensor where it is influenced by the supply air;

the sensor gives inaccurate readings if the supply air is blown

directly onto the sensor or if the supply air does not have a

chance to mix with the room air before it is drawn into the re-

turn airstream.

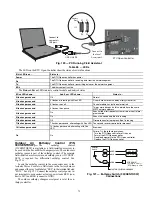

Wiring the Indoor Air Quality Sensor — For each sensor,

use two 2-conductor 18 AWG (American Wire Gage) twisted-

pair cables (unshielded) to connect the separate isolated 24 vac

power source to the sensor and to connect the sensor to the con-

trol board terminals.

To connect the sensor to the control, identify the positive (4

to 20 mA) and ground (SIG COM) terminals on the sensor. See

Fig. 87. Connect the 4-20 mA terminal to the RTU Open con-

troller at J4-2 and connect the SIG COM terminal to the RTU

Open controller at J4-3. See Fig. 113.

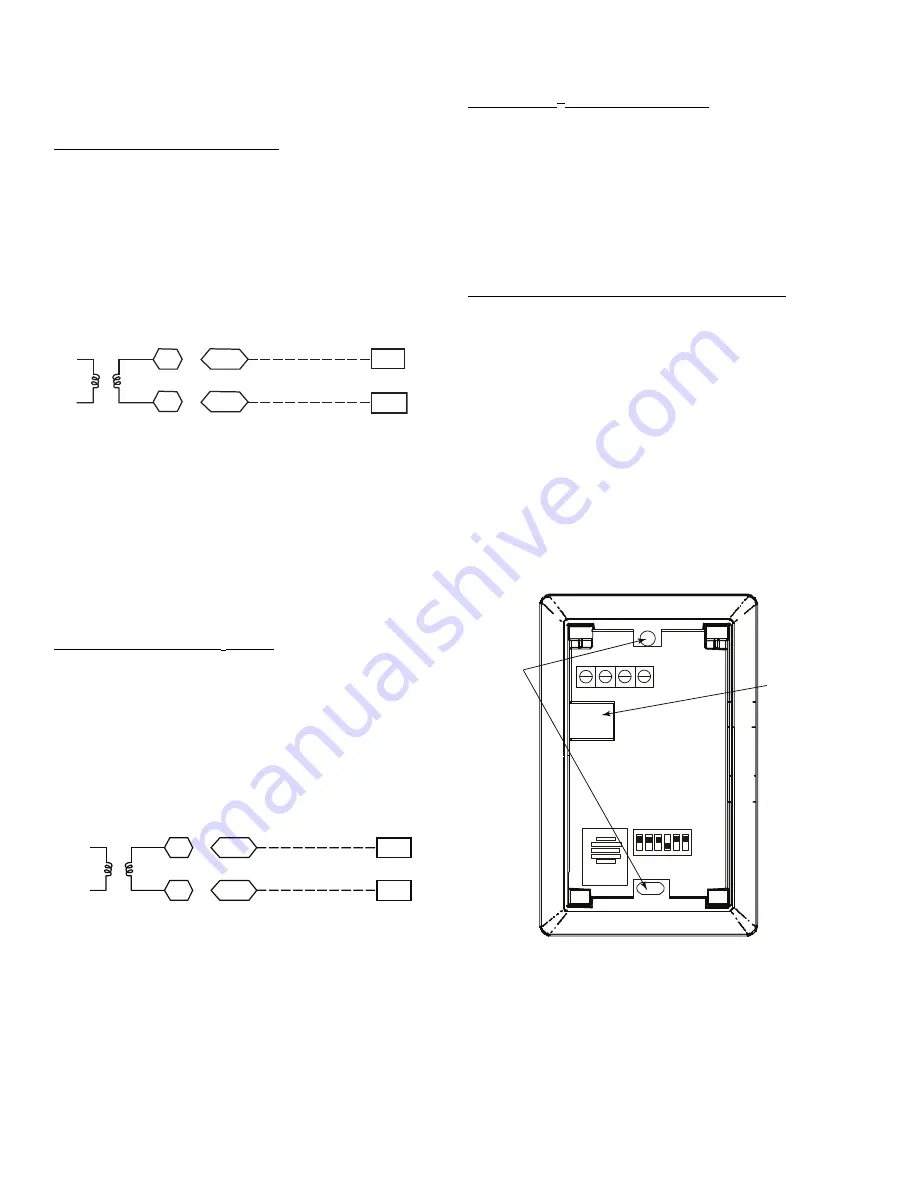

Fig. 113 — RTU Open Controller/Indoor CO

2

Sensor (33ZCSPTCO2-01 or 33ZCSPTCO2LCD-01)

Connections

OUTDOOR AIR QUALITY SENSOR (P/N 33ZCSPT-

CO2-01 OR 33ZCSPTC02LCD-01 PLUS WEATHER-

PROOF ENCLOSURE) — The outdoor air CO

2

sensor is

designed to monitor carbon dioxide (CO

2

) levels in the outside

ventilation air and interface with the ventilation damper in an

HVAC system. The OAQ sensor is packaged with an outdoor

cover. See Fig. 90. The outdoor air CO

2

sensor must be located

in the economizer outside air hood.

Wiring the Outdoor Air CO

2

Sensor

—

A dedicated power

supply is required for this sensor. A two-wire cable is required

to wire the dedicated power supply for the sensor. The two

wires should be connected to the power supply and terminals 1

and 2.

To connect the sensor to the control, identify the positive (4

to 20 mA) and ground (SIG COM) terminals on the OAQ sen-

sor. See Fig. 87. Connect the 4 to 20 mA terminal to the RTU

Open controller at J4

—

5. Connect the SIG COM terminal to

the RTU Open controller at J4

—

Fig. 114 — RTU Open Controller/Outdoor CO

2

Sensor (33ZCSPTCO2-01 or 33ZCSPTCO2LCD-01)

Connections

SPACE RELATIVE HUMIDITY SENSOR OR HUMIDI-

STAT

Humidi-MiZer

®

System Control Wiring

—

In units equipped

with the Humidi-MiZer option there are two loose wires loose

in the control box (one PNK and one PNK/BLK) used to con-

trol the dehumidification function of the unit. These wires are

meant to be tied to a space humidistat or thermidistat on an

electromechanical unit. On RTU Open controller equipped

units these wires must be connected to J11-7 and 8 to allow the

Open board to operate the dehumidification function for the

unit. Disconnect the J11 Phoenix style connector from the

board and use the plug screws to secure the wires as follows:

secure the PNK/BLK wires at pin 7 and the PNK wires at pin

8, and then reconnect the plug to the board at J11.

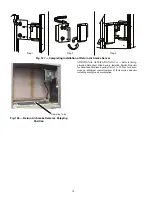

Relative Humidity Sensors (Space or Duct Mounted)

—

The

accessory space humidity sensor (33ZCSENSRH-02) or duct

humidity sensor (33ZCSENDRH-02) is used to measure the

relative humidity of air within the space or return air duct. The

RH reading is used to control the Humidi-MiZer option of the

rooftop unit. For wiring distances up to 500 ft (152 m), use a 3-

conductor, 18 or 20 AWG shielded cable. The shield must be

removed from the sensor end of the cable and grounded at the

unit end. The current loop power for sensor is provided by the

RTU Open controller as 24 vdc. Refer to the instructions sup-

plied with the RH sensor for the electrical requirements and

terminal locations. RTU Open controller configurations must

be changed after adding an RH sensor. See Fig. 115 and 116 for

typical RH sensor wiring.

• J4

—

1 or J4

—

4 = 24 vdc loop power

• J4

—

2 or J4

—

5 = 4-20 mA signal input

NOTE: The factory default for dehumidification control is nor-

mally open humidistat.

Fig. 115 — Space Relative Humidity Sensor

Typical Wiring

SEN

COM

J4-2

J4-3

IAQ Sensor

24 VAC

SEN

COM

J4-5

J4-6

OAQ Sensor

24 VAC

SW2

1

2

3

4

5

6

ON

Io

Vin

Gnd

Vo

MOUNTING

HOLES

WIRING

OPENING

Vin - J4-1 or J4-4 24Vdc

Io - J4-2 or J4-5 -20mA output

Summary of Contents for Carrier WeatherMaker 50TC A08 Series

Page 4: ...4 Fig 2 Unit Dimensional Drawing Size 08 09 12 Units...

Page 5: ...5 Fig 2 Unit Dimensional Drawing Size 08 09 12 Units cont...

Page 6: ...6 Fig 3 Unit Dimensional Drawing Size 14 Unit...

Page 7: ...7 Fig 3 Unit Dimensional Drawing Size 14 Unit cont...

Page 9: ...9 Fig 4 Unit Dimensional Drawing Size 16 Unit cont...

Page 13: ...13 Fig 8 Roof Curb Details Size 16 Unit...

Page 50: ...50 Fig 73 50TC 16 Control Box Component PremierLink Locations...

Page 51: ...51 Fig 74 Typical PremierLink Control Wiring Diagram...

Page 52: ...52 Fig 75 Typical PremierLink Control Wiring Diagram with Humidi MiZer System Option...

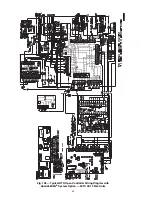

Page 64: ...64 Fig 106 Typical RTU Open Controller Wiring Diagram 50TC 08 14 Size Units...

Page 65: ...65 Fig 107 Typical RTU Open Controller Wiring Diagram 50TC 16 Size Unit...