Compressor Unit Instruction Manual

Appendix D

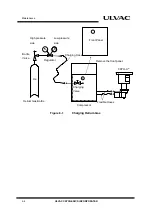

FLOW DIAGRAM

Helium returning from cold head is transferred to the compressor with oil injected and

then compressed. The oil is pooled at the bottom of the compressor inside and

circulated passing through the oil heat exchanger, filter, orifice, solenoid valve and sight

glass.

The compressed high-pressure and high-temperature helium is discharged from the

compressor pump and transferred to the helium heat exchanger. As passing through the

heat exchanger, the heat generated during compression is removed and then the cooled

helium enters oil separator. Inside the oil separator, the oil droplet contained in helium

is removed and returns to the compressor unit after passing through a filter and a

orifice.

At the same time, the helium from oil separator enters an adsorber. As passing through

the adsorber, oil mist contained in helium is removed by adsorption and the helium is

supplied to the cold head via flexible hose.

ULVAC CRYOGENICS INCORPORATED

D-1

Summary of Contents for C10T

Page 2: ......

Page 8: ...F 6 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank ...

Page 14: ...S 4 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank ...

Page 16: ...IW 2 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank ...

Page 32: ...Operation 4 2 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank ...

Page 44: ...Troubleshooting A 4 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank ...

Page 47: ...Compressor Unit Instruction Manual ULVAC CRYOGENICS INCORPORATED B 3 B 4 ...

Page 48: ...Compressor Unit Instruction Manual ULVAC CRYOGENICS INCORPORATED B 5 B 6 ...

Page 50: ...Flexible Hose C 2 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank ...

Page 54: ...CS 2 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank ...

Page 56: ...This page intentionally left blank R 2 ULVAC CRYOGENICS INCORPORATED ...