PAGE 14 OF 33

1219 IH-8105

NOTE: The I/Os will only work when the I/O

Option Board has been installed.

The option I/O board provides two isolated inputs and

four dry-contact normally open relay outputs which can

be used for simple process weighing.

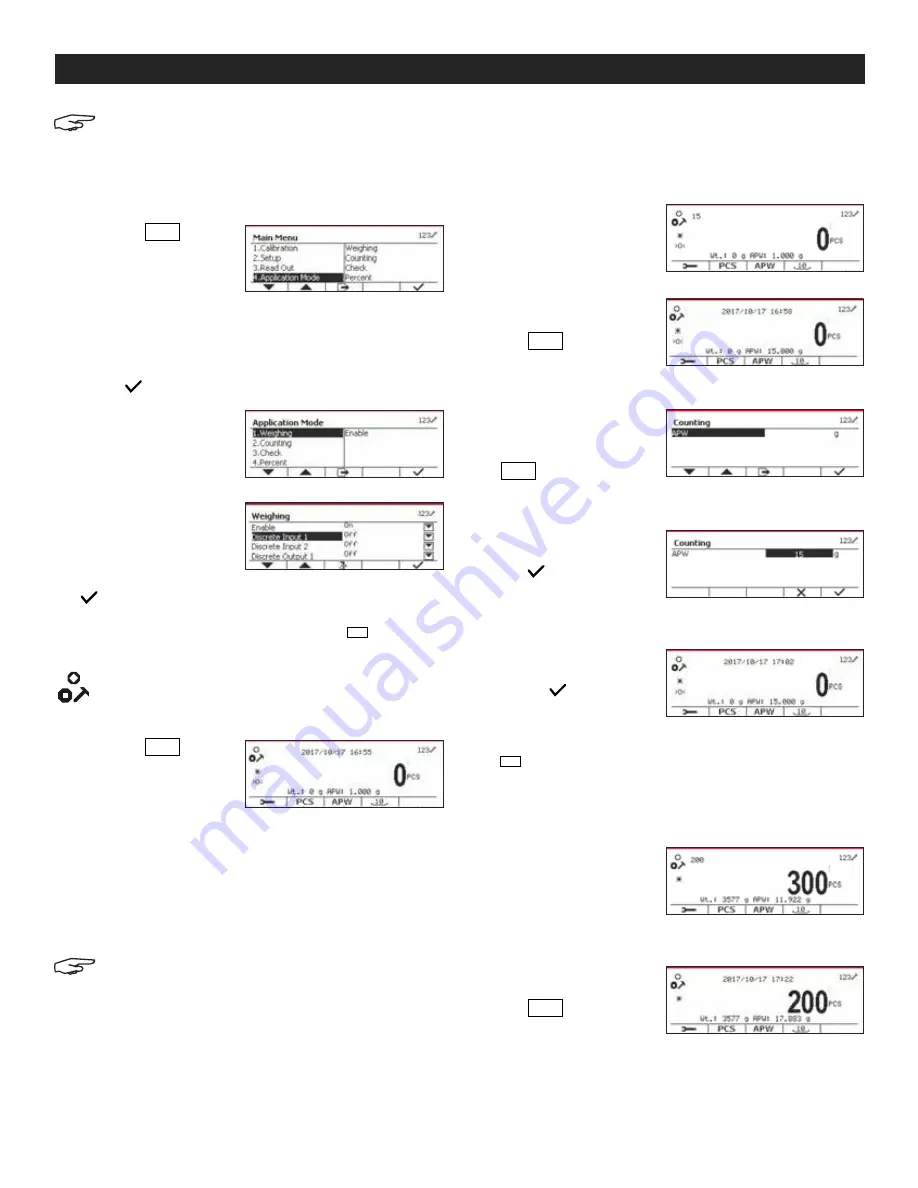

1. Press the

Menu

User

button

to enter the Main Menu.

(See Figure 36)

2. With the button corresponding to the

▼

icon, go

down the list and highlight Application Mode. Enter

this submenu by pressing the button corresponding

to the

icon. (See Figure 36)

3. In the Application

Mode menu, enter the

Weighing submenu.

(See Figure 37)

4. The Weighing submenu

is now displayed.

Select the list item

and press the button

corresponding to the

icon to change

the setting as desired. After completion of I/O setup,

press the softkey corresponding to the

Menu

User

icon to

return to the main application screen. (See Figure 38)

COUNTING

Use this application to count samples of uniform weight.

1. Press the

Mode

Library

button until the icon

corresponding to

Counting is displayed

on the screen. The

default (or last) Average Piece

Weight (APW) is displayed. (See Figure 39)

2. Set the APW value (see below) and then place

objects on the pan to display the number of pieces.

SET THE AVERAGE PIECE WEIGHT (APW)

NOTE: It is recommended that the APW is larger

than 1d. If APW is between 0.05d and 1d, a

warning message will be displayed and the

information line will show "APW is too small!". If

APW is less than 0.05d, an error message will

appear, and the APW value cannot be stored.

There are two methods to set the APW:

ENTERING A KNOWN APW

Method 1

1. Key in the Piece Weight

using the alphanumeric

keypad. (See Figure 40)

2. Press the softkey

corresponding to

the

APW

icon.

(See Figure 41)

Method 2

1. Alternatively, first

press the softkey

corresponding to the

APW

icon to enter the

submenu for setting the

APW. (See Figure 42)

2. Press the softkey

corresponding to

the

icon to edit

the APW value using

the alphanumerical

keypad. (See Figure 43)

3. After editing, press the

softkey corresponding

to the

icon for

confirmation, and

then press the softkey

corresponding to the

Menu

User

icon to exit the submenu. (See Figure 44)

CALCULATING AN APW

Method 1

1. Place the sample on

the pan and then key

in the number of

pieces using the

alphanumeric keypad.

(See Figure 45)

2. Press the softkey

corresponding to

the

PCS

icon for

confirmation. The

terminal will calculate

the new APW using the

number of pieces.

(See Figure 46)

APPLICATIONS CONTINUED

Figure 36

Figure 37

Figure 38

Figure 39

Figure 40

Figure 41

Figure 42

Figure 43

Figure 44

Figure 45

Figure 46