49

85816

Replacement of the conveyor belt may be necessary if

it is worn, has been damaged, or will no longer stay in

proper alignment and adjustment.

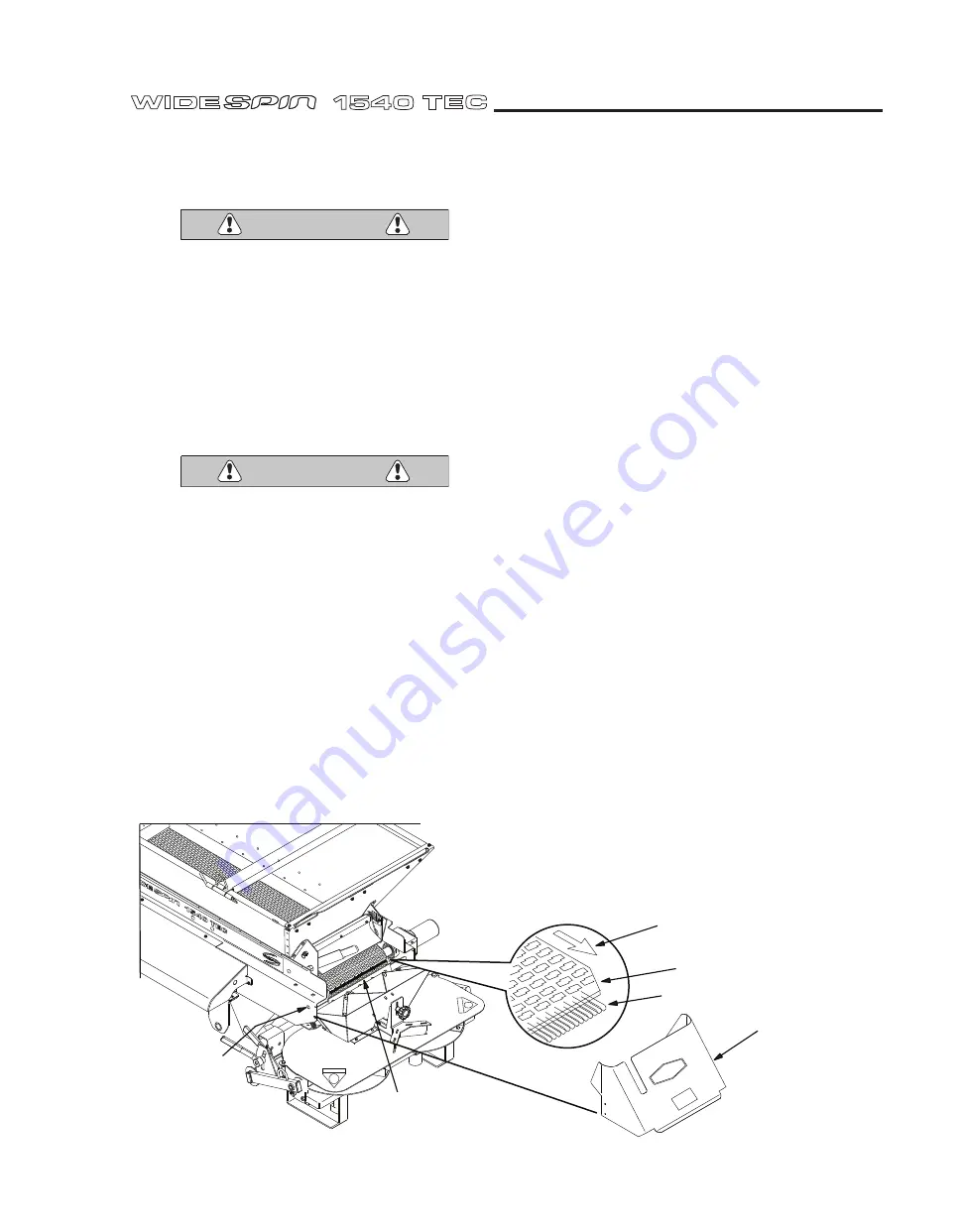

Refer to Figure 38.

TO AVOID SERIOUS INJURY,

Work Safely!! Wear the Appropriate Safety Gear.

Do Not Attempt to Service or Adjust Any Part of

the Top Dresser When it is Operating.

REMOVAL OF OLD CONVEYOR BELT

Step 1.

Operate the conveyor until the splice in the

belt is in line with the hole in the rear of the frame.

Check that the splice wire can be removed through

the hole without interference from the frame. For

safety, stop the trucks engine and disconnect the

electrical connections from the truck.

TO AVOID SERIOUS INJURY,

Disconnect The Electrical Connection From The

Truck.

Step 2.

Remove the rear deflector.

Step 3.

Open the metering gate to the largest

opening.

Step 4.

Remove the conveyor belt scraper.

Step 5.

Release the tension on the conveyor belt by

loosening both conveyor belt adjusting screws. Push

the front roller towards the back of the machine to

ensure that all tension is released.

Step 6.

Locate the splice wire. Straighten the ends

so that it can be removed. Remove the splice wire

through the hole in the frame.

Step 7.

Remove the belt by pulling it out from the top.

Conveyor Belt Replacement

Step 8.

Clean the pan and plastic pan cover. Inspect

for wear and sharp edges that may damage the new

conveyor belt. Clean and inspect the front conveyor

belt idler roller and the rear conveyor drive roller.

Check the bearings on the front and rear rollers.

INSTALLATION OF THE NEW CONVEYOR BELT

Step 9.

The conveyor belt is directional and must be

inserted in the proper direction to ensure that the

splice does not catch on other components. Identify

the difference in the belt ends by looking for the end

without the 45° degree angle cut. This end (without

the 45° cut) will be inserted into the WideSpin 1540

TEC first.

With the pattern up, insert the belt past the metering

gate, and into the hopper. Make sure that the

conveyor belt is under the hopper seals. Continue

to insert the belt over the pan and around the front

idler roller. Continue under the pan until the two

ends meet at the rear roller.

Step 10.

Align the ends of the conveyor belt near the

splice removal hole in the frame. Join the ends of

the belt at the splice. NOTE: Both outside edges of

the belt must be perfectly aligned with each other

or tracking and belt alignment problems will result.

Insert the splice wire and link the two ends of the

conveyor belt together. Slightly bend both ends of

the splice wire to secure it in the conveyor belt.

Step 11.

Reset conveyor belt tension to both conveyor

belt adjuster screws. Refer to the “Conveyor Belt

Tension Adjustment” section in this manual.

Step 12.

Replace and adjust the conveyor belt scraper.

Replace the rear deflector. Reinstall the electrical

connection to the tow vehicle.

Step 13.

Operate the conveyor and check the belt.

The belt must not catch on the hopper seals, or

rub on any frame or drive component. Refer to

the “Conveyor Belt Tracking Adjustment” sections

in this manual. Follow instructions for tracking

adjustments and “Break-In” procedures.

FIGURE 38

REAR

DEFLECTOR

45° DEGREE CUT END

CONVEYOR

BELT SPLICE

SPLICE

BELT MOVEMENT

DURING OPERATION

SV85816-11

REMOVE

SPLICE

WIRE THROUGH

HOLE

WARNING

WARNING

SERVICE LEVEL MAINTENANCE