Maintenance

Check Fuel Filter and Tank

Service Interval: Before each use or daily

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Check the fuel filter and tank for leaks. See

Engine Owner's Manual.

Lubricate Grease Fittings

Note:

See chart for service intervals.

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Lubricate fittings with NLGI grade #2

multi-purpose gun grease.

Refer to the maintenance chart for fitting

locations and lubrication schedule.

Lubrication Chart

Fitting

Locations

Initial

Pumps

Number of

Places

Service

Interval

1. Front Caster

Pivots

*0

2

Yearly

2. Idler Pivot

1

1

Yearly

*See step 3 for special lubrication instructions on

the caster pivots.

3.

Lubricate caster pivots once a year. Remove hex

plug and cap. Thread grease zerk in hole and

pump with grease until it oozes out around top

bearing. Remove grease zerk and thread plug back

in. Place cap back on.

Check Condition of Belt

Service Interval: Every 40 hours

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Check the belt condition and tension.

Check Spark Plugs

Service Interval: Every 100 hours

Remove spark plugs, check condition and reset gaps,

or replace with new plugs. See Engine Owner's

Manual.

Wheel Hub–Slotted Nut

Torque Specification

Service Interval: After the first 100 hours

Every 500 hours thereafter

Torque the lug nuts on the wheel hub to 95 ft-lb (129

N-m).

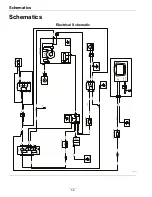

Check Alternator

Service Interval: As required

20 Amp Regulated Alternator

The 20 amp regulated alternator system provides

AC current through two output leads to the

regulator-rectifier. The regulator-rectifier converts

the AC current to DC, and regulates current to the

battery. The charging rate will vary with engine RPM

and temperature.

1.

Stator assembly (1) (Figure 35)

2.

Two YELLOW leads (2) from Stator.

3.

RED DC output lead (3) from connector.

4.

Connector (4)

5.

Two YELLOW AC input leads (5)

6.

Regulator-rectifier (6)

7.

RED DC output lead (7) to connector

Note:

Stator (1), regulator-rectifier (6) and fly-wheel

are NOT INTERCHANGEABLE with any other

charging system.

48

Summary of Contents for Z-SPRAY JUNIOR Series

Page 1: ...Z SPRAY JUNIOR SERIES For Serial Nos 411 294 212 Higher Part No 4505 818 Rev A...

Page 60: ...Notes 60...

Page 61: ...Notes 61...

Page 62: ...Service Record Date Description of Work Done Service Done By 62...

Page 63: ...63...