Maintenance

filter, are removed or any of the hydraulic lines are

disconnected.

1.

Stop engine and wait for all moving parts to stop.

Raise the rear of the machine up onto jack stands

high enough to raise the drive wheels off the

ground.

2.

Check oil level as stated in

Check Hydraulic Oil

Level

section.

3.

Start engine and move throttle control ahead to

full throttle position. Move the speed control

lever to the middle speed position and place the

drive levers in the “drive” position.

4.

Open the drive wheel release on each pump.

5.

With the machine running, stroke the drive levers

from forward to reverse several time, slowly.

Then, retighten the drive wheel release valves.

Note:

If either drive wheel does not rotate, it

is possible to assist the purging of the charge

pump by carefully rotating the tire in the forward

position.

6.

If either drive wheel still does not rotate, stop and

repeat steps and above for the respective pump. If

wheels rotate slowly, the system may prime after

additional running. Check oil level as stated in

Check Hydraulic Oil and Tank Level

section.

7.

Allow the machine to run several minutes after

the charge pumps are “primed” with drive system

in the full speed position. Check oil level as stated

in

Check the Hydraulic Oil Level

section.

8.

Check hydro drive linkage adjustment as stated in

Hydro Drive Linkage Adjustment

section in

Adjustments.

Check Tire Pressures

Service Interval: Every 50 hours

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Check tire pressure in drive tires.

3.

Inflate all tires to 18 psi (124 kPa).

Check Spreader System

Service Interval: Every 50 hours

Spray the hopper cables, accuway cable, and the

deflector shield cable with silicone spray if needed.

Clean the bottom of the hopper with a wire brush

and clean off any fertilizer if needed.

Change out the hopper bottom bushing or the

impeller if needed.

Check Sprayer System

Service Interval: Every 50 hours

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Check all hoses, nozzles, and fittings for leaks.

3.

Check nozzle strainers and in-line strainers.

4.

Replace as needed.

Check In-line Filter

Service Interval: As required

Periodically check the in-line filter for any debris in

the screen. If debris is present, this can create erratic

pressure spikes and/or not allow the proper flow

through system. After clearing any debris, ensure that

gasket remains intact and tighten in-line filter cap (if

not installed properly, this will allow air to get in the

system and system will lose or not create pressure).

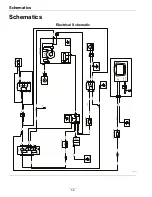

g311410

Figure 34

1.

Cap

3.

Filter

2.

Gasket

4.

In-line filter housing

47

Summary of Contents for Z-SPRAY JUNIOR Series

Page 1: ...Z SPRAY JUNIOR SERIES For Serial Nos 411 294 212 Higher Part No 4505 818 Rev A...

Page 60: ...Notes 60...

Page 61: ...Notes 61...

Page 62: ...Service Record Date Description of Work Done Service Done By 62...

Page 63: ...63...