AB Connectors Limited

Specification No. 528

ABCIRP Connector Series

Assembly and wiring Instructions

AB Connectors Limited Issue 9: July 2010

Page 39 of 41

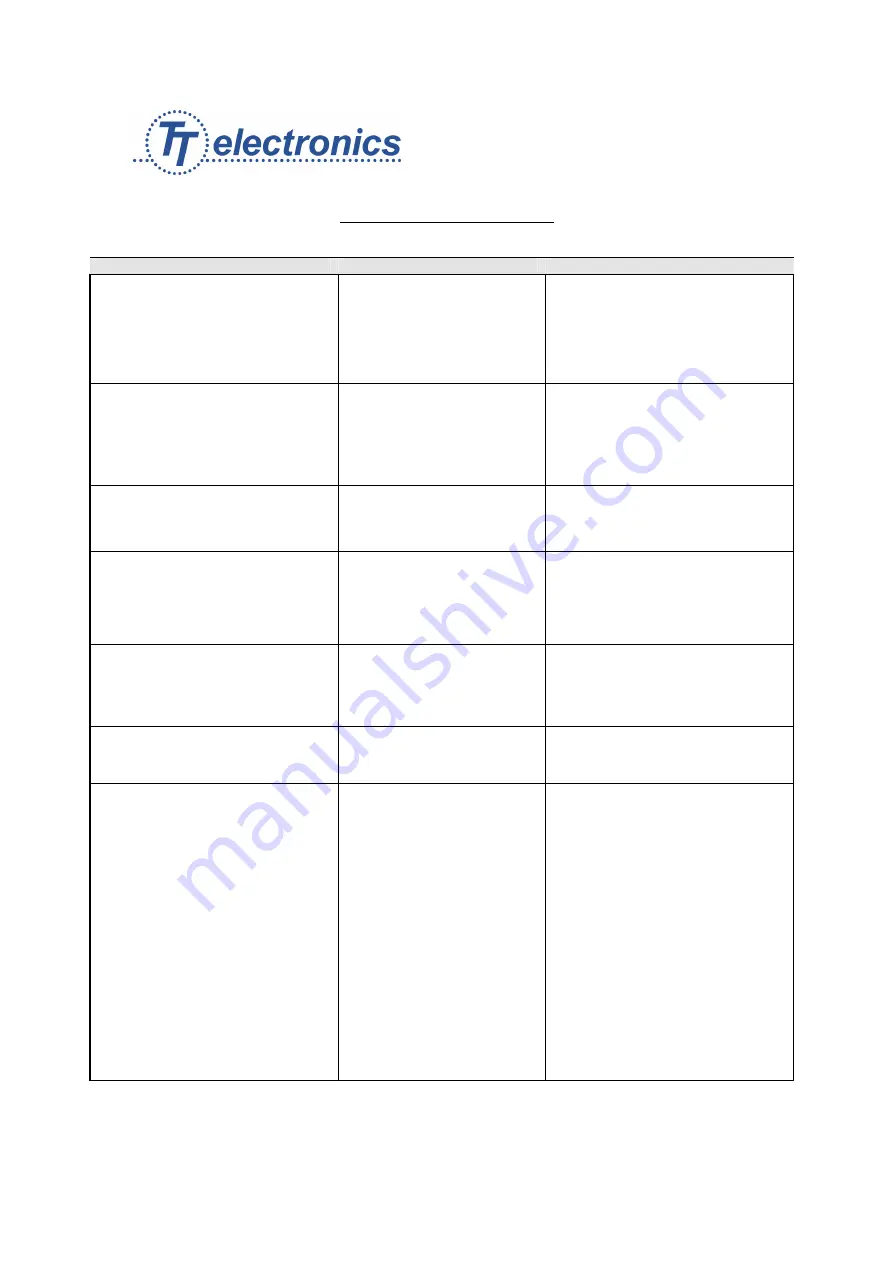

Appendix F: Trouble Shooting.

Symptom:

Common Cause:

Solution:

Uneven contact heights in the connector

The contact is not fully inserted in

the insulator. However there is a

small amount of movement, which is

acceptable when the contact is

correctly seated.

Using the appropriate contact insertion tool,

reapply pressure to fully locate the contact. If

the problem persists, remove the contact

and inspect the retaining clip for damage.

Connector un-couples in use.

Connectors not fully coupled.

Rotate the coupling nut until an audible

‘snap’ is heard and the coloured dots on the

fixed and free shells are aligned. Depending

on the size of the mating connectors, a

mechanical device like a strap will ease the

final stage of the coupling operation.

Poor crimp performance, e.g. low cable pull

out forces; high resistance etc..

Incorrect crimp tool settings or

conductors cut during the stripping

operation.

Use correctly calibrated tools and settings.

Adjust the stripping tool depth so that only

the insulation is cut.

Contacts short to shell or across contacts.

1.Foerign objects between insulator

and grommet or connector faces.

2. Water Ingress.

1. Check for swarf or conductor strands on

connector faces.

2. Dry out the connector, check the grommet

and retighten the backshell to the specified

torque value.

Water Ingress to Backshell

1. No grommet.

2. Incorrect cable for grommet.

3. Loose backshell/accessory

4. Grommet damaged during contact

insertion.

5. Grommet not seated correctly.

1. Fit Grommet.

2. Build-up insulator diameter 3.Check for

grommet/damage.

4. Tighten to specified value.

5. Reseat grommet fully.

Securing band will not hold the screen

Band only wrapped around once

before tightening.

Wrap the band twice around the backshell

before tightening.

Contacts push back when connectors are

mated

1. Contacts not fully inserted

2. Attempting to couple connectors

with different insulator orientations

3. Contacts bent.

4. Retention clip damaged during

extraction.

1. Using the appropriate contact insertion

tool, re-apply pressure to fully locate the

contact.

2. Check orientations before mating.

3. Replace bent contacts.

4.

Replace clip or contact.

5.

If a push back occurs prior to connector

mating (during push back check) then it

is certain that the contact was not fully

locked into position and can be simply

pushed forward until it is locked.

6.

If a push back contact occurs post

connector mating, then it is not certain

why the failure occurred, so the plastic

insulator should be replaced in case

any damage has occurred to the

plastic. In addition, the contact should

be checked for signs of damage,

particular attention should be given to

the retention legs. If the contact is

damaged then it should also be

replaced.