AB Connectors Limited

Specification No. 528

ABCIRP Connector Series

Assembly and wiring Instructions

AB Connectors Limited Issue 9: July 2010

Page 17 of 41

inserting the contact into the insert until it clicks into place. When inserting a socket

contact it is good practice to place a socket guide pin in the front of the contact to

prevent any rubber from the grommet web entering the socket contact.

5.4.9

Slide the tool out and remove the tool from the wire.

Hint: When sliding the tool out lightly apply tweezers action to the open the tool. This

will help prevent chafing the wire insulation on the tool.

Hint: As each contact is inserted pull firmly on the cable to ensure that the contact has seated

correctly. Any contact not seated correctly will pull back. If this happens use the insertion tool

and reinsert the contact and repeat the pull test.

5.4.10 Repeat steps 5.5.8 to 5.5.9 for all wires.

5.4.11 Checking the dimensions shown in Appendix B will verify that the contact is seated

correctly. As an extra final visual check, all contacts should be around the same

height with no visible differences in height from insert face.

5.4.12 Assemble the rear backshells and accessories following steps 5.4.8 to 5.4.11.

2. Contact Extraction

2.1.1

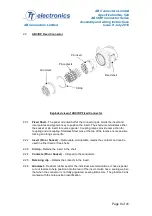

The extraction tool can be utilised for both the size 16 and 12 contacts, by replacing

the probe with the appropriate size. These probes can become damaged over time

and therefore can be easily replaced. See Appendix A for details of the replacement

probe part numbers.

2.1.2

Loosen cable accessory and backshell. Slide these down the cable to allow easy

access to the rear of the connector. Slide the grommet and cable idents back

approximately 70mm.

2.1.3

Working from the front face of the connector, position the extraction tool over the pin

or socket contact. Carefully rotate the tool until the 3 slots in the tool align with the 3

ribs in the insert cavity. Push the tool firmly into the insert closing the clip with the

front collar.