AB Connectors Limited

Specification No. 528

ABCIRP Connector Series

Assembly and wiring Instructions

AB Connectors Limited Issue 9: July 2010

Page 14 of 41

Completed crimp contact

5.2.11 Check that the conductor strands are visible through the inspection hole.

Important Note: Loose conductor strands or cracks in the crimp area are not

acceptable.

The crimp joint must be re-made if there is any sign of damage.

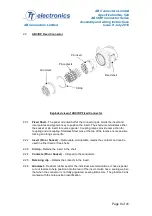

5.3 Contact Insertion – Method 1

5.3.1

Push the contacts through the grommet according to the wiring list / schedule and

push the grommet up to, but not beyond the idents. Lubricant such as Pronatur or

Isoproyl alcohol may be used. Important: Observe handling and operating safety

instructions as supplied by manufacture.

5.3.2

Locate the correct hole for the appropriate wire. Load the contact into the insert by

hand. Note: It is best practice to work from one side only, inserting from left to right or

top to bottom in an orderly fashion. Some arrangements have a radial pattern where

working from the centre and working outwards is best. Randomly inserting contacts is

more likely to result in wiring errors and difficulty inserting contacts.

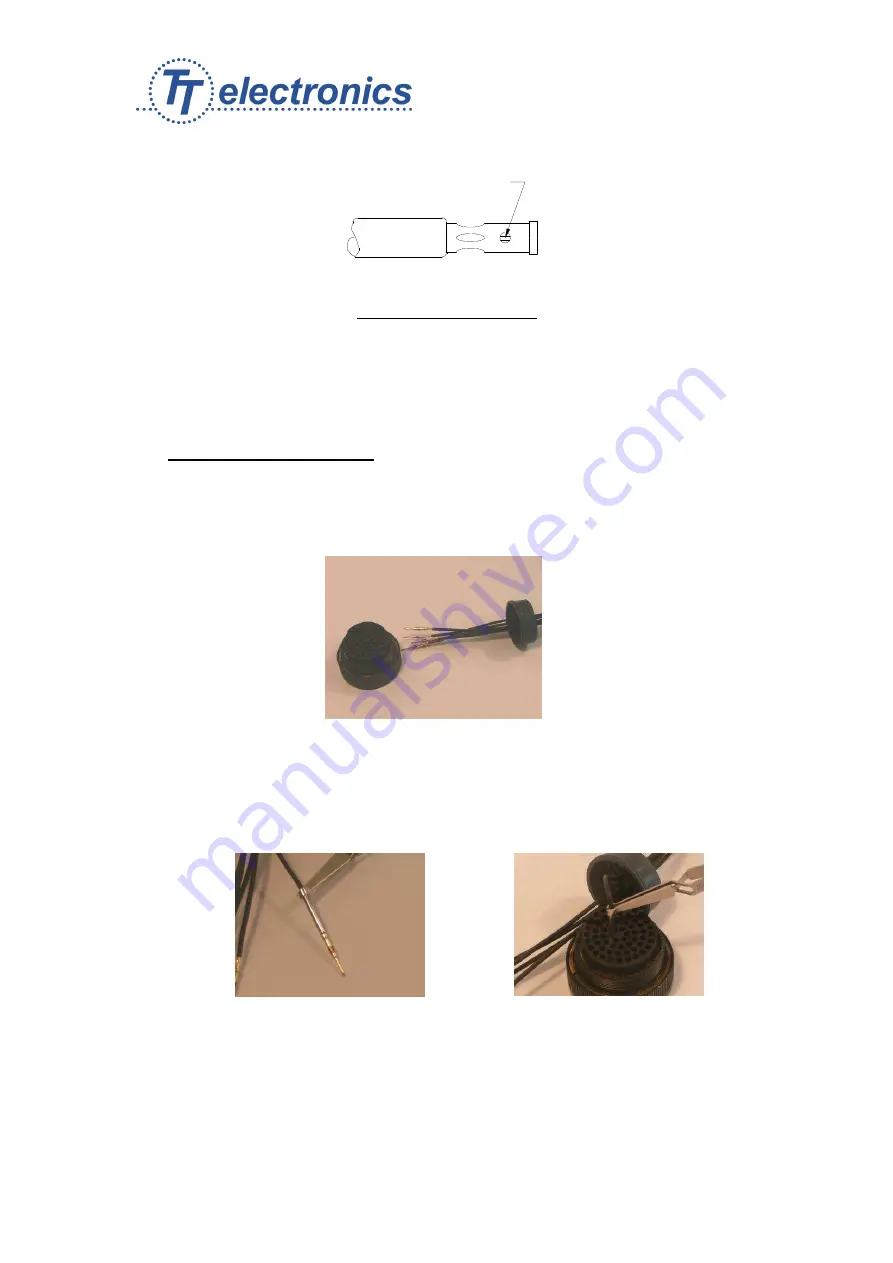

5.3.3

Using the correct insertion tool for the contact as shown above, locate onto contact

bucket and push the contact forward until fully inserted, when a ‘click’ will be heard

and felt.

Hint: As each contact is inserted pull firmly on the cable to ensure that the contact has seated

correctly. Any contact not seated correctly will pull back. If this happens use the insertion tool

and reinsert the contact and repeat the pull test.

Inspection H ole