Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

The Triatek HMS-1650 Series Fume Hood Controller is an ultra-sensitive

instrument used to monitor and/or control the fume hood face velocity in

laboratories and clean rooms. This unit is a precision measuring system

capable of measuring and displaying face velocities from zero to 200 ft/

min (1.016 m/sec) with an accuracy of ±2 ft/min.

Key features of the HMS-1650 include:

• Comprehensive closed-loop sash control with sidewall velocity

sensing

• Full-color touchscreen display with programmable display options and

adjustable backlight

• Intuitive user interface simplifies setup and configuration of unit

• Display background changes color to indicate hood status at a glance

• Audible and visual alarm annunciation

• Auxiliary universal analog inputs for use with optional sensors

• Four independent PID control loops for controlling damper actuators,

speed drives, hot water valves, humidifiers, etc.

• Digital input used to monitor an optional fume hood sash switch, zone

presence sensor, or emergency override switch

• Relay outputs used for transmitting alarm condition to remote location

• Dedicated thermistor inputs for temperature monitoring and/or control

applications

• Multi-level password protection of touchscreen user interface

• Field Calibration of both sidewall velocity sensor and optional sash

position sensor

• Multi-protocol native (BACnet®, Metasys® N2) for easy integration

with any BMS

• Manual override of Analog and Relay outputs assist with Test &

Balance procedures

• Comprehensive Real-Time View diagnostics tool displays built-in to

each unit

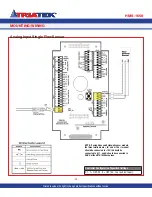

• Easy-to-install backplane/backplate assembly facilitates permanent

termination of all wiring

The HMS-1650 is equipped with a 3.2” diagonal

Full-color

Touchscreen

display in portrait orientation (240 x 320). The password-

protected menu tree is very intuitive and simplifies the setup and

configuration of the unit. The menus incorporate touch-based interfaces

such as sliders, radio buttons, and dialog popups to facilitate the ease-

of-use of the HMS-1650.

The display implements bright background color changes to indicate the

three different

Alarm Status

indications of the monitored fume hood.

These background colors indicate “Normal” when the face velocity is

within defined limits, “Warning” when the face velocity is nearing an out-

of-limits condition, and “Alarm” when the face velocity is outside defined

acceptable limits. The face velocity ranges for these conditions are

easily set by the user for the specific installation when necessary. The

background color changes provide an overview of the monitored fume

hood face velocity conditions at a glance.

Alarm conditions

may be defined by the user, in terms of desired face

velocity settings for the fume hood being monitored. When an alarm

condition occurs, it may be annunciated in four user-definable ways: 1)

on the display, 2) with an audible alarm, and 3) transmitted via contacts

to a remote monitoring location and 4) over the BMS network. The alarm

will automatically reset when the unit has sensed that the fume hood

face velocity has returned to proper limits. The operator may easily mute

the audible alarm by touching the OK button on the alarm notification

message popup window of the touchscreen display.

For many applications, it is important to have other variables such as

sash position or ambient temperature displayed along with the fume

hood face velocity. The HMS-1650 provides for this by means of three

additional

Universal Analog Inputs

, each of which may be configured

for either current loop operation or voltage input operation (0-5V, 1-5V,

0-10V, 2-10V, 0-20mA, 4-20mA). Each input may be scaled as needed

to display correct values, and may have an engineering units selection

associated. The configuration of each analog input is field selectable

through the use of miniature dipswitches on the controller unit.

For those applications requiring monitoring and/or control based

on temperature variances, the HMS-1650 provide two dedicated

Thermistor Inputs

in addition to the four universal analog inputs.

Therefore, a total of six analog inputs are available for control

applications. The two thermistor inputs may be used with negative

temperature coefficient (NTC) Type 2 or Type 3 sensors.

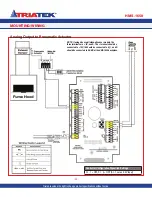

The HMS-1650 provides four

Universal Analog Outputs

, which may

be configured for either current loop operation or for voltage operation.

Each analog output may be configured for proportional operation to

provide a linear signal to the BMS, or for PID (proportional-integral-

derivative) control operation for closed-loop feedback control of

damper actuators, variable frequency (speed) drives, hot water valves,

humidifiers, or other analog-controlled devices. Each universal analog

output may be field-configured for the required application using onboard

configuration dipswitches on the controller module. Each analog output

GENERAL

Overview

HMS-1650

Triatek reserves the right to change product specifications without notice.

-

8

-

Triatek reserves the right to change product specifications without notice.