CTV-SVX009D-GB

47

11

UNT-PRC002-GB

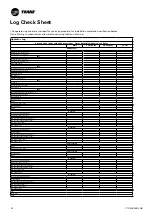

Sound power levels

Discharge

Measurement conditions:

Measurements taken in a room adjacent to the room containing the FWD, at the outlet of the rectangular duct (1.5 m

long) fixed to its discharge opening.

Fan

Power level in dB(A), per Hz frequency band

Overall power

Unit

speed

125

250

500

1000

2000

4000

8000

dB(A)

1

55

50

42

37

37

31

30

46

FWD 08

2

57

54

47

40

30

38

40

50

3

58

57

50

42

32

40

43

53

1

57

51

45

42

34

33

28

48

FWD 10

2

58

54

48

45

38

39

35

51

3

60

58

50

48

40

42

39

54

1

57

51

45

42

34

33

28

48

FWD 12

2

58

54

48

45

38

39

35

51

3

60

58

50

48

40

42

39

54

1

56

62

50

48

39

38

36

56

FWD 14

2

61

66

55

53

47

46

45

60

3

63

69

58

56

50

50

49

63

1

57

63

51

49

40

39

37

57

FWD 20

2

61

66

55

53

47

46

45

60

3

63

69

58

56

50

50

49

63

Intake

Measurement conditions:

Measurements taken at the horizontal air intake.

Fan

Power level in dB(A), per Hz frequency band

Overall power

Unit

speed

125

250

500

1000

2000

4000

8000

dB(A)

1

56

55

55

53

46

45

42

57

FWD 08

2

63

62

60

60

53

53

53

64

3

66

65

63

62

56

55

57

67

1

62

58

55

58

51

48

44

61

FWD 10

2

66

63

60

62

56

55

52

66

3

70

67

63

65

59

59

57

69

1

62

58

55

58

51

48

44

61

FWD 12

2

66

63

60

62

56

55

52

66

3

70

67

63

65

59

59

57

69

1

66

65

65

65

57

50

46

68

FWD 14

2

73

72

69

71

64

59

57

74

3

78

76

73

75

69

64

63

78

1

68

72

64

64

56

52

50

69

FWD 20

2

76

76

68

71

65

61

61

75

3

78

79

71

74

69

66

66

78

Unit Start Up Procedures

Daily Unit Start Up

The timeline for the sequence of operation begins with a

power-up of the main power to the chiller. The sequence

assumes 2 circuits, with one or two compressors, Sintesis

Excellent GVAF chiller with no diagnostics or malfunctioning

components. External events such as the operator placing

the chiller in AUTO or STOP, chilled water flow through the

evaporator, and application of load to the chilled-water loop

causing loop water-temperature increases, are depicted

and the chiller responses to those events are shown, with

appropriate delays noted. The effects of diagnostics, and

other external interlocks other than evaporator water-flow

proving, are not considered.

Note: unless the UC800 TD7 and building automation system

are controlling the chilled-water pump, the manual unit start

sequence is as follows. Operator actions are noted.

General

If the present checkout, as discussed above, has been

completed, the unit is ready to start.

1. Press the STOP key on the TD7 display.

2. As necessary, adjust the set point values on the

TD7 menus using Tracer TU.

3. Close the fused-disconnect switch for the chilled-water

pump. Energize the pump(s) to start water circulation

4. Check the service valves on the discharge line, suction

line, oil line, and liquid line for each circuit. These

valves must be open (back seated) before starting the

compressors.

5. Verify that chilled-water pump runs for at least one

minute after the chiller is commanded to stop (for

normal chilled-water systems).

6. Press the AUTO key. If the chiller control calls for cooling,

and all safety interlocks are closed, the unit will start. The

compressor(s) will load and unload in response to the

leaving chilled – water temperature;

After the system has been operating for approximately 30

minutes and has become stabilized, complete the remaining

start up procedures, as follows:

1. Check the evaporator refrigerant pressure and the

condenser refrigerant pressure under Refrigerant Report

on the TD7.

2. Check the EXV sight glasses after enough time has

elapsed to stabilize the chiller. The refrigerant flow

through the sight glasses should be clear. Bubbles in

the refrigerant indicate either low refrigerant charge

or excessive pressure drop in the liquid line, or an

expansion valve that is stuck open. A restriction in

the line can sometimes be identified by a noticeable

temperature differential between the two sides of the

restriction. Frost will often form on the line at this point.

Proper refrigerant charges are shown in the General

Information Section;

3. Measure the system discharge superheat.

4. Clean the air filter located on the door of the control

panel of AFD if required.

Note:

The system cannot be pumped down due to the surge

characteristics of centrifugal compressors.

Inverted Start, commonly called “Monday Morning Start

Up”, can be a situation containing a high evaporation

load (high building heat inertia). This inertia may lead

to compressor capacity limitations due to choke at low

pressure ratio.

IMPORTANT NOTICE

- Do not use recycled refrigerant as it may contain oil, which

can affect system reliability. The refrigerant should be pure

and stored in virgin containers

- Hoses should be free of oil

- Do not attempt more than three restarts after a critical

fault. Continued attempts may cause the shaft to

degmagnetize. Please contact OEM service provider.

Seasonal Unit Startup Procedure

1. Close all valves and reinstall the drain plugs in the

evaporator.

2. Service the auxiliary equipment according to the startup

and maintenance instructions provided by the respective

equipment manufacturers.

3. Close the vents in the evaporator chilled-water circuits.

4. Open all the valves in the evaporator chilled-water

circuits.

5. Open all refrigerant valves.

6. If the evaporator was previously drained, vent and fill

the evaporator and chilled-water circuit. When all air is

removed from the system (including each pass), install

the vent plugs in the evaporator water boxes.

7. Check the adjustment and operation of each safety and

operating control.

8. Close all disconnect switches.

9. Refer to the sequence for daily unit start up for the

remainder of the seasonal start up.

System Restart after Extended

Shutdown

1. Verify that the liquid-line service valves, compressor

discharge service valves, and optional suction service

valves are open (back seated)

2. Fill the evaporator water circuit. Vent the system

while it is being filled. Open the vent on the top of the

evaporator while filling, and close it when filling is

completed.

3. Close the fused-disconnect switches that provide power

to the chilled-water pump.

4. Start the evaporator water pump and, while water is

circulating, inspect all piping for leakage. Make any

necessary repairs before starting the unit.

5. While the water is circulating, adjust the water flow and

check the water pressure drops through the evaporator.

Refer to “water-system flow rates” and “water-system

pressure drop”

6. Adjust the flow switch on the evaporator piping for

proper operation

7. Stop the water pump. The unit is now ready for startup

as described “Startup procedures”

CAUTION!

To prevent damage to the compressor, ensure that

all refrigerant valves are open before starting the unit. Do

not use untreated or improperly treated water. Equipment

damage may occur.