CTV-SVX009D-GB

44

4

UNT-PRC002-GB

Technical Data

FWD

08

12

20

30

45

Power supply

(V/Ph/Hz)

230/1/50

Capacities

Cooling capacity on water (1)

(kW)

5,2

8,3

15

18,8

30,1

Heating capacity on water (2)

(kW)

6,3

11,9

18,9

20,9

38,2

Fan motor

(type)

2 x direct drive centrifugal

Fan power input (3)

(kW)

0,23

0,46

0,65

1,04

1,51

Current amps (3)

(A)

1,1

2,2

3,1

4,7

5,5

Start-up amps

(A)

3,2

5,5

9,3

14,1

16,5

Air flow

minimum

(m

3

/h)

490

980

1400

1800

2700

nominal

(m

3

/h)

820

1650

2300

3000

4500

maximum

(m

3

/h)

980

1970

2600

3600

5400

Main coil

Water entering/leaving connections

(type)

ISO R7 rotating female

(Dia)

3/4"

3/4"

1 1/2"

1 1/2"

1 1/2"

Electric heater (accessory for blower only)

Electric power supply

(V/Ph/Hz)

230/1/50

230/1/50 or 400/3/50

400/3/50

400/3/50

400/3/50

Heating capacity

(kW)

2/4

8

10

12

12

Hot water coil (accessory for blower only)

Heating capacity (4)

(kW)

6,3

12

17,4

22,4

34,5

G2 filter (filter box accessory)

Quantity

2

2

2

2

2

Dimensions ( LxWxth)

(mm)

386x221x8

486x271x8

586x321x8

586*421*8

586*621*8

G4 filter (filter box accessory)

Quantity

-

2

2

2

2

Dimensions ( LxWxth)

(mm)

-

486x264x48

586x314x48

586*414*48

586*614*48

Condensate pump (accessory)

(type)

Centrifugal

Water flow - lift height

(l/h - mm)

24 - 500

Not available for FWD30 and FWD45

Sound level (L/M/H speed)

Sound pressure level (5)

(dB(A))

36/40/43

38/41/44

46/50/53

47/52/57

47/52/58

Sound power level (5)

(dB(A))

46/50/53

48/51/54

56/60/63

57/62/67

57/62/68

Unit dimensions

Width x Depth

(mm)

890 x 600

1090 x 710

1290 x 820

1290 x 970

1290 x 1090

Height

(mm)

250

300

350

450

650

Shipped unit dimensions

Width x Depth

(mm)

933 x 644

1133 x 754

1333 x 864

1333 x 1008

1333*1133

Height

(mm)

260

310

360

460

660

Weight

(kg)

32

46

61

76

118

Colour

galvanised steel

Recommended fuse size

Unit alone (aM/gI)

(A)

8/16

8/16

8/16

8/25

8/25

Unit with electric heater (gI)

(A)

16 (2kW),25 (4kW)

40 (230V),3*16 (400V)

3*20

3*25

3*25

(1) Conditions: Water entering/leaving temperature: 7/12 °C, Air inlet temperature 27/19°C DB/WB - Nominal air flow

(2) Conditions: Water entering/leaving temperature: 50/45 °C, Air inlet temperature 20°C DB - Nominal air flow

(3) At high speed with nominal air flow.

(4) Water entering/leaving temperature 90/70 °C, air inlet temperature 20 °C DB, Nominal air flow.

(5) A rectangular glass wool duct 1m50 long is placed on the blower.The measurement is taken in the room containing the blower unit.

Heat exchanger operating limits:

FWD:

*water temperature: max 100° C

*absolute service pressure: min 1 bar/max 11 bars

Accessories - Hot water coil:

*water temperature: min. +2° C/max. 100° C

*absolute service pressure: min 1 bar/max 11 bars

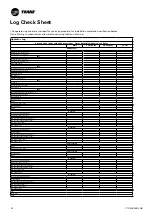

Pre-Start Checkout

Installation Checklist

Complete this checklist as the unit is installed, and verify

that all recommended procedures are accomplished

before the unit is started. This checklist does not replace

the detailed instructions given in the “Installation

Mechanical” and “Installation Electrical” sections of this

manual. In addition, compressor details can be found

in the compressor service documentation. Make sure

to have this documentation prior to any intervention.

Read all sections completely, to become familiar with the

installation procedures, prior beginning the work.

General

When installation is complete, before starting the unit,

the following prestart procedures must be reviewed and

verified:

1. Inspect all wiring connections in the compressor

power circuits (disconnects, terminal block, contactors,

compressor junction box terminals and so forth) to

ensure they are clean and tight.

2. Open all refrigerant valves in the discharge, liquid, and

oil return lines.

3. Check the power-supply voltage to the unit at the main-

power fused-disconnect switch. Voltage must be within

the voltage use range and also stamped on the unit

nameplate. Voltage fluctuation must not exceed 10%.

Voltage imbalance must not exceed 2%

4. Check the unit power phasing L1-L2-L3 in the starter

to ensure that it has been installed in a “A-B-C” phase

sequence.

5. Grounding is essential for the safe operation of the unit :

failure to do so may result in reliability failure

1) Verify continuity of all ground connections.

2) Ensure solid ground connections (both mechanical

and electrical).

3) At one point, usually the entrance of the power supply

panel, all grounds should be connected together

4) All electrical instruments must be rated to 1kVAC and

600VDC. This includes voltage leads and probes.

6. Fill the evaporator chilled-water circuit. Vent the system

while it is being filled. Open the vents on the top of the

evaporator water box while filling and close when filling

is completed.

7. Close the fused-disconnect switch(es) that supplies

power to the chilled-water pump starter.

8. Start the chilled-water pump to begin circulation of

the water. Inspect all piping for leakage and make any

necessary repairs.

9. With water circulating through the system, adjust the

water flow and check the water pressure drop through

the evaporator.

10. Adjust the chilled-water flow switch for proper operation.

11. Reapply power to complete the procedures

12. Prove all Interlock and Interconnecting Wiring Interlock

and External as described in the Electrical Installation

section.

13. Check and set, as required, all UC800 TD7 menu items.

14. Stop the chilled-water pump.

15. Do not use recycled refrigerant as it may contain oil,

which can affect system reliability. The refrigerant should

be pure and stored in virgin containers

- Hoses should be free of oil

Unit Voltage Power Supply

Unit voltage must meet the criteria given in the

installation Electrical Section. Measure each lead of

the supply voltage at the main power fused-disconnect

switch for the unit. If the measured voltage on any lead

is not within the specified range, notify the supplier of

the power and correct the situation before operating the

unit.

Unit Voltage Imbalance

Excessive voltage imbalance between the phases of a

three-phase system can cause motors to overheat and

eventually fail. The maximum allowable unbalance is

2%. Voltage imbalance is determined using the following

calculations:

% Imbalance = [(Vx – Vave) x 100/Vave]

Vave = (V1 + V2 + V3)/3

Vx = phase with greatest difference from Vave (without

regard to the sign)

Unit Voltage Phasing

It is important that proper rotation of the compressors

be established before the unit is started. Proper motor

rotation requires confirmation of the electrical phase

sequence of the power supply. The motor is internally

connected for clockwise rotation with the incoming

power supply phases A-B-C.

When rotation is clockwise, the phase sequence is

usually called “ABC”, when counterclockwise “CBA”

This direction may be reversed by interchanging any two

of the line wires.

1. Stop the unit from TD7/UC800.

2. Open the electrical disconnect or circuit protection

switch that provides line power to the line power

terminal block(s) in the starter panel (or to the unit

mounted disconnect).

3. Connect the phase-sequence indicator leads to the line

power terminal block as follows;

Phase Sequence Lead

Terminal

Black (Phase A)

L1

Red (Phase B)

L2

Yellow (Phase C)

L3