60

TRAK Machine Tools

Southwestern Industries, Inc.

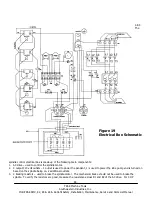

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

Rarely do both the X and Y motor/servo systems fail at the same time and in the same way. So, if your problem is

occurring on both axes, its source is probably somewhere else.

4.4.1 Cable Connections

Check the motor cable connections on the cable breakout box. Verify there are no pushed in pins on the connector.

4.4.2 To Check the Motor Encoders

If the motor encoder inside the motor has failed or is not reading the machine will fault out on that axis. Do the

following to verify this problem:

Motor encoder only machines – run Service Codes 100 or 131. This will display on the DRO if the motor encoder is

counting. If the axis does not count, the encoder is not counting. This means either the encoder or the cable is the

problem. Visually check the cable for any problems. If the encoder has failed the motor must be replaced.

Motor encoder and secondary feedback machines – run Service Codes 100 or 131. Both the motor encoder and sensor

or glass scale encoder should count on the DRO screen. The motor value should be displayed under the Z-axis and the

sensor or glass scale under the X or Y-axis depending on which axis you are doing.

4.4.3 Encoder Counts to Pendant

Before replacing the motor due to a bad motor encoder it is a good idea to check the cables that take those signals back

to the pendant. If these signals are not getting back to the pendant then the axis will fault. Check the following cable

connections.

Umbilical #1 and #2 at the cable breakout box

Umbilical #1 and #2 at the pendant

Umbilical #1 carries the X and Y-axis signals and Umbilical #2 carries the Z signals.

4.4.4 Moving Problem from One Axis to Another

Another way to troubleshoot a problem with a particular axis is to swap parts from 1 axis to another to see if the

problem moves. If the problem moves then that component is faulty. See the example below.

Symptom – X Axis will not move and faults

This particular problem can happen because of any of following reasons: bad motor, servo driver, or computer module.

In some cases it is not obvious which component is causing the problem. This example will help us pinpoint the problem

through a trial and error process.

Let’s assume we have narrowed it down to the servo or electrical systems and the Y-axis has no problems. Lets also

assume it is not an obvious problem like a loose connection.

Swap these components

Results

Physically switch the X and Y

motors

Has problem moved to Y-axis? If yes, replace motor. If no,

the motor is not the problem.

4.5 Servo Driver

Note: the Servo Driver is located in the black box on the side of each motor.

Indications:

Problems moving just one axis, including hard turning in one or both directions.

Servo Types:

X and Y servos are identical