141

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

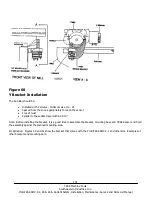

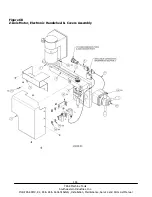

Caution!

Do not over tighten the bolt; this may damage the bolt, the quill threads or

deform the quill.

Note:

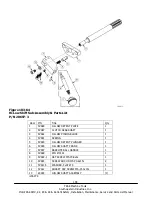

Various components on Figure 67 have multiple balloons due to these parts varying on different machines.

Note:

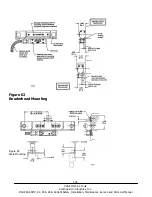

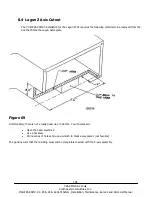

The overall strategy is:

The position locator (9), and the hex head screw (18) align the baseplate side to side.

The leveling nuts (17) align the baseplate front to back.

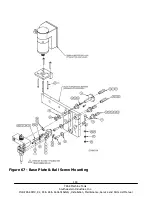

2.

Replace the machine’s head bolts with the Jackscrew nuts (items 12 through 16) on the right side. Replace the

machine’s head bolts with the socket head couplers on the left side. Items 12 through 16 vary depending on

the type of head the kit is being installed on.

3.

Tighten these incrementally to 50 ft/lb. or the mill manufacturer’s spec for the head bolts.

4.

Install the fork on the quill. Tighten to 25 ft/lb. Use locktite, a lockwasher and the setscrews provided. The

forks vary from kit to kit.

Note: The fork must move smoothly in the slot, otherwise it will have to be modified

.

5. Install the position locator (Item 9) where the feed control was located.

6. Install the leveling nuts on the position locator and the jackscrew nuts.

7.

Install the base plate with the hex head screw (Item 18) through the hole where the threaded rod used to

be. Use shim between the block and baseplate if necessary.

Note: for shipping, the ball screw and covers are mounted to the base plate. Remove them before installing the base

plate.

8.

Install the baseplate with the nut and washers as shown. Use the leveling nuts to align the baseplate to the

travel of the quill front to back. Also, align the baseplate side to side by placing the level on the right edge

of the baseplate and comparing it to the extended quill. Tighten the nuts to 25 - 35 ft/lb.

Note: The baseplate must be parallel to the travel of the quill for the assembly to work properly. Use a bubble level

on the quill to compare it to the front and side of the base plate. Check the alignment frequently, especially after

installing and tightening the 1/2 - 13 x 1 1/2” socket screws (Item 30).

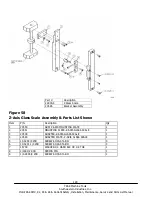

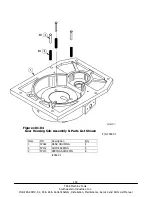

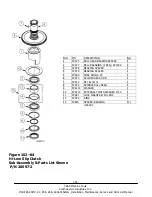

Parts List – Base Plate & Ball Screw Mounting (Figure 67)

Item

P/N

Description

Use As Qty

1

16215

BRACKET BALLNUT-MACHINED (FORK)

EA

1

2

16353-1

BRACKET BALLNUT MACHINED - ACER/MILLPORT

EA

1

4

16357-1

BRACKET BALLNUT FORK EXTENDED LAGUN SM16

EA

1

5

16355-1

SCREW 3/8-24 BRKT BALLNUT MOUNTING

EA

1

7

16364-1

SCREW M10-1.0 BRKT BALLNUT MOUNTING

EA

1

8

16364-2

SCREW M10 X 1.5 BRKT BALLNUT MOUNTING

EA

1

9

16210

POSITIONER LOCATOR

EA

1

10

16212-12

COUPLING SOCKET HEAD

EA

2

11

16212-13

COUPLING SOCKET HEAD

EA

2

12

16213-13

JACKSCREW NUT 1/2-13--1/2-13

EA

2

13

16213-12

JACKSCREW NUT 1/2-12--1/2-13

EA

2

14

16213-175L

JACKSCREW NUT M12-1.75--1/2--13

EA

2

15

16213-12L

JACKSCREW NUT 1/2-12--1/2--13

EA

2

16

16213-175

JACKSCREW NUT M12-1.75--1/2-13

EA

2

17

16214

NUT LEVELING 3/4-16

EA

3

18

16216

SCREW HEX HD

EA

1