116

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

19.

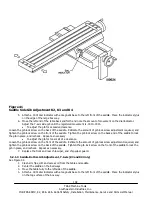

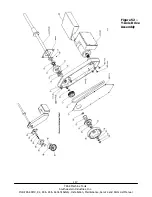

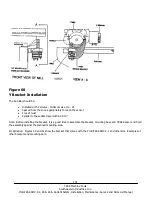

Pull the saddle all the way forward and install the ball screw into the yoke with 5/16-

18 x 1 3/4” screws. The flat of the ballnut flange should match up with the flat on

the yoke. These flats are there so that the yoke and ballnut will clear the bevel gear.

Check that these clear now by pushing the saddle back.

If the yoke provided in the kit does not clear the bevel gear, it will be necessary to

remove enough material from it so that it will clear.

Also check that the elbow fitting will clear the casting at the top front of the knee. If

it interferes, it will be necessary to screw it down more, or grind away the casting to

clear.

20.

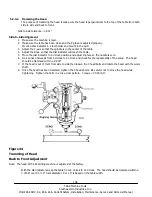

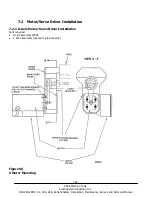

Route the oil line up through the hole in the saddle to the right rear of the yoke, trim it appropriately and

attach it to one of the oil lines of the machine.

(Kit Variation: some machines do not have separate oil lines running to each leadscrew. Use the supplied T fitting to

route oil to each ball screw.)

CAUTION!

Make sure that the oil line will not be sheared by the sliding

covers when the saddle moves.

(Kit Variation: on machines with oil restrictors on the yoke, use the supplied brass fitting and the original restrictor.)