100

TRAK Machine Tools

Southwestern Industries, Inc.

ProtoTRAK SMX, K2, K3 & K4 & Retrofit Safety, Installation, Maintenance, Service and Parts List Manual

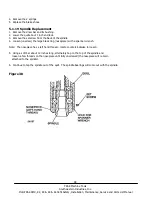

5.2 Maintenance

5.2.1 Gib Adjustments

The objective of adjusting the gibs is to eliminate as much play in the table, saddle and ram sliding surfaces as

possible without having the tightness of the gib interfere with their free movement and cause a decrease in the

accuracy and/or performance of the machine due to excessive friction.

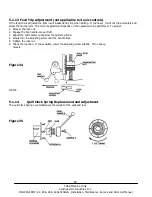

5.2.1.1 Table Gib Adjustment, X-Axis

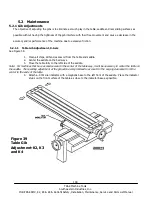

See Figure 39.

1.

Clean all chips, dirt and excess oil from the table and saddle.

2.

Center the saddle on the bed ways.

3.

Move the table fully to the left side of the saddle.

Note: For machines that have excessive wear in the center of the table way, it will be necessary to center the table on

the saddle. The resulting adjustment of the gib will be compromised to account for the varying clearance from the

center to the ends of the table.

4.

Attach a .0001 dial indicator with a magnetic base to the left front of the saddle. Place the indicator

stylus on the front surface of the table as close to the indicator base as possible.

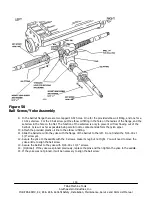

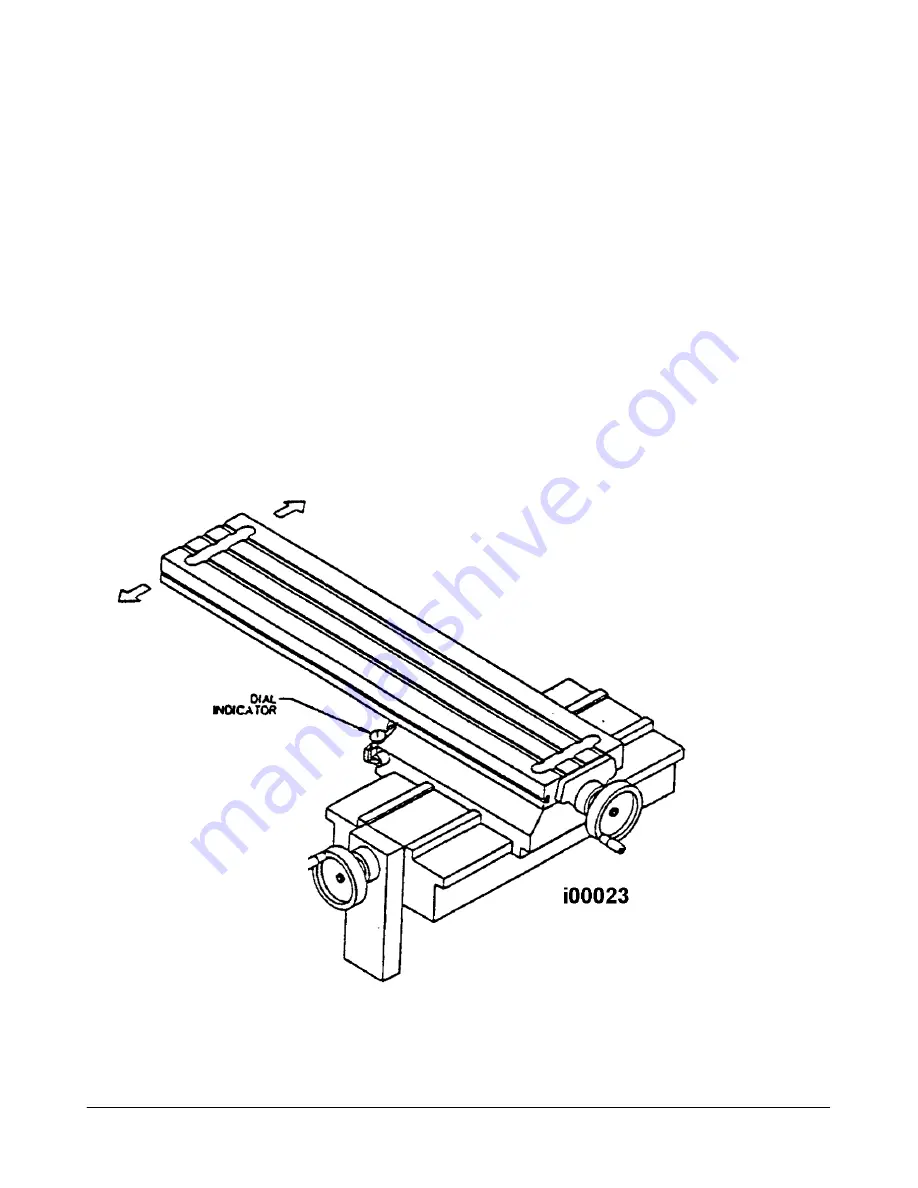

Figure 39

Table Gib

Adjustment-K2, K3

and K4