Winch Operation Warnings Continued

16. Winch rope:

• Be sure that the rope is in good condition and is attached properly.

• Do not use the winch if rope is frayed.

• Do not move the vehicle to pull a load.

• Do not replace the rope with a rope of lesser strength.

• The life of the rope is directly related to the use and care it receives. Following its fi rst and

subsequent uses, a rope must be wound onto the drum under a load of at least 500lbs

(230kgs) or the outer wraps will draw into the inner wraps and severely damage the rope

during the winching. The fi rst winch use should be a familiarization run while in a relaxed,

non-recovery situation. Spool out the rope until the red rope mark appears (about 8 wraps remaining

on the drum), and then rewind the rope on the drum under a load of 500lbs (230kgs) or more.

• When the rope is replaced, be sure to apply a thread locking compound to the rope clamp

thread. Tighten the clamp screw properly but do not over tighten. The thread locking compound

will prevent loosening of the screw in arduous conditions.

17. Do not attempt to exceed the pulling limits of the winch.

18. Do not drive your vehicle to assist the winch in any way. Vehicle

movement in combination with winch operation may overload the

rope, the winch itself or cause damaging shock loads!

19. Shock loads when winching are dangerous! A shock load occurs when an increase force is

suddenly applied to the rope. A vehicle rolling back on a slack rope may induce a damaging

shock

load.

20. The winches shown in this manual are solely for vehicle and non-industrial applications.

21. Do not use winch in hoisting applications due to required hoist safety factors and features.

22. Do not use the winch to lift, support or otherwise transport personnel.

Installation

Mounting your Winch

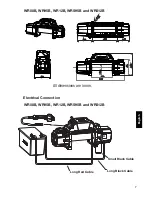

1. The winch is to be mounted into a suitable sized mounting frame using the 4 point foot

mounting system in either a horizontal or vertical plane.

• It’s very important that the winch be mounted on a fl at surface so that the three sections

(motor, rope drum and gear housing) are properly aligned.

•

•

The fi tment of winches and/or a frontal protection system may affect the triggering of SRS air

bags. Check that the mounting system has been tested and approved for winch fi tment in the

air bag equipped vehic

Always verify area is clear of fuel lines, fuel tank, brake lines, electrical wires, etc.

when drilling.

le.

2. Winch mounting frames and/or frontal protection systems are suggested to suit most popular

vehicle. Winch frames are packaged with detailed fi tting instructions.

3. The winch should be secured to the mounting with the hardware included with your winch.

4. The fairlead is to be mounted so as to guide the rope onto the drum evenly.

English

6

Summary of Contents for Reflex WR08B

Page 1: ...English Owner s Manual Francais Espa ol...

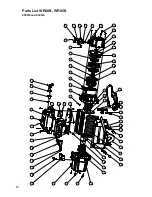

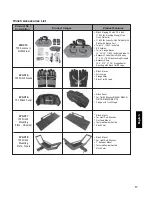

Page 12: ...8000lb and 9500lb Parts List WR08B WR95B 12...

Page 13: ...12000lb Parts List WR12B English 13 English...

Page 14: ...14 Parts List WRS95B and WRS12B 9500lb 12000lb...

Page 20: ......

Page 21: ...Treuil Manuel d utilisateur Francais...

Page 32: ...8000 livres et 9500 livres Liste des pi ces de WR08B WR95B 32...

Page 33: ...12000 livres Liste des pi ces de WR12B 33 Francais...

Page 34: ...Liste des pi ces de WRS95B et WRS12B 9500 livres et 12000 livres 34...

Page 40: ......

Page 41: ...Winch de remolque Manual de usuario Espa ol...

Page 52: ...8000lb 9500lb Lista de Partes WR08B WR95B 52...

Page 53: ...12000lb Lista de Partes WR12B 53 Espa ol...

Page 54: ...Lista de Partes WRS95B WRS12B 9500lb 12000lb 54...