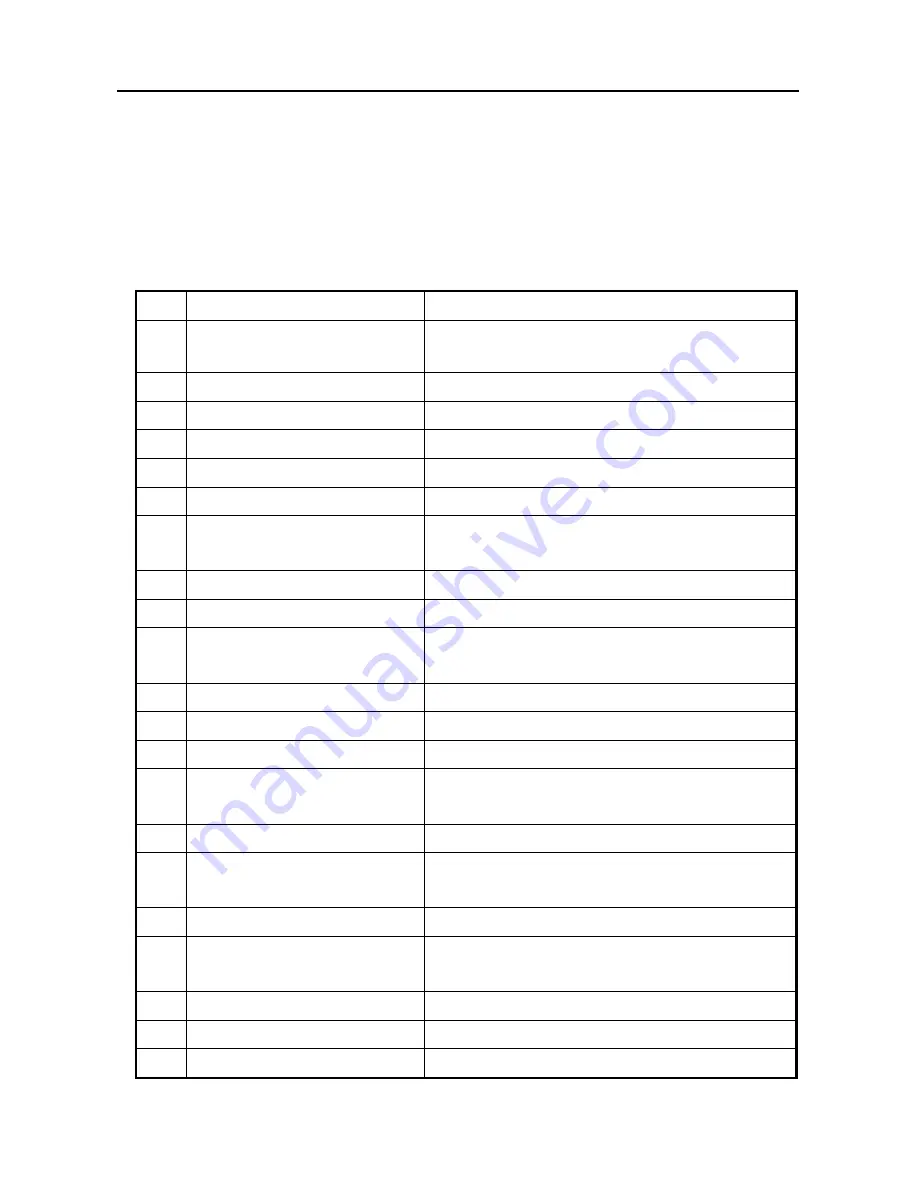

1.SPECIFICATIONS

1.SPECIFICATIONS

ESP9000

No

Item

Specifications

1

Type of stitch

Lock stitch type sewing machine (for automatic embroidery

only)

2

Rotary hook

Vertical 2 revolution type (eccentric)

3

Thread take-up lever

Cam take-up lever

4

Needle bar stroke

50 ± 0.2 mm

5

Number of needles

15 (auto changing)

6

Applicable needles

Organ DB×K5Z #11

7

Presser foot

Needle bar linked driving system (with noise

reduction mechanism)

8

Bobbin thread winding

Semi-auto winding (auto return, also stop)

9

Thread trimming method

Horizontal reciprocation (motor drive)

10 Thread wiper

Motor drive sliding type (with thread retaining

mechanism)

11 Picker method

Picking at start, end of sewing and cutting thread

12 Stitch speed

1,200spm maximum (800spm standard)

13 Embroidery area

360 mm long × 500 mm wide

14 Embroidery

control

and

indication

Touch switch control with LED/LED displays

15 Stitch memory

280,000 stitches

16 Memory back-up

Memory saved during operation and after power off;

kept for 4 weeks

17 Weight

80 ± 1kg (without table)

18 Machine oil

High grease NX 2, molybdenum grease NO 2, SF oil

(multi-grade)

19 Drive motor

AC servo motor (machine revolution)

20 Control motor

AC servo motor (X axis, Y axis)

21 Needle thread failure detection

Rotary detection system (photo sensor)

-1-

Summary of Contents for ESP9000

Page 1: ...SERVICE MANUAL Embroidery Machine ESP9000 15 needles...

Page 2: ......

Page 13: ...FIG 3 48...

Page 24: ...FIG 4 59...

Page 36: ...Connection of connector CN 10 Must be connected correctly Replace See P 47 CN10 11...

Page 40: ...Picker height C 7 9 mm when piker solenoid is ON Adjust See P 27 15...

Page 58: ...FIG 2 FIG 3 201 3 0 1 0 3 mm 22...

Page 63: ...FIG 4 e Drive arm FIG 5 27...

Page 70: ...FIG 3 34...

Page 72: ...FIG 2 FIG 3 201 3 0 1 0 3 mm 22...

Page 74: ...FIG 2 FIG 3 Needle bar Stopper Needle bar Connecting stud 24...

Page 77: ...FIG 4 e Drive arm FIG 5 27...

Page 84: ...FIG 3 34...

Page 86: ...FIG 4 31...

Page 88: ...FIG 4 33...

Page 90: ...FIG 2 35...

Page 93: ...2 a Sensor arm 3 38...

Page 95: ...FIG 3 FIG 4 VR6 Power supply board 40...

Page 97: ...FIG 3 FIG 4 0 5 to 0 8mm 0 2mm or less Hook support hook support 37...

Page 100: ...FIG 4 40...

Page 103: ...FIG 2 Needle bar c Top dead center stopper needle bar connecting stud FIG 3 43...

Page 105: ...FIG 5 45...

Page 111: ...Printed in Japan 2002 8...