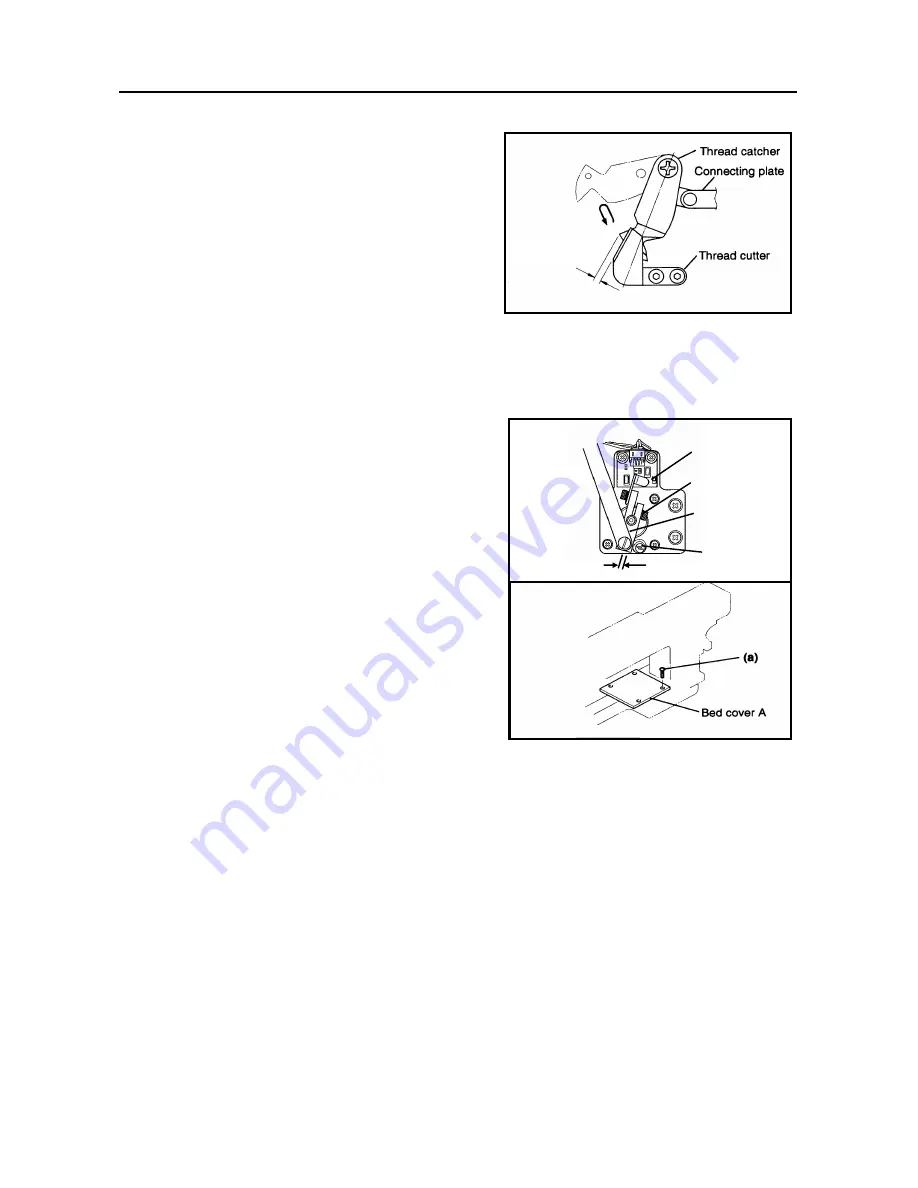

3.ADJUSTMENT

3-3 Standby position of thread

catcher

[Inspection]

(1) Remove the needle plate.

(2) Remove the table set.

(3) Turn the power on and press the

thread trim key to perform the thread

trimming.

(4) The relative positions of the thread

catcher and the thread cutter must be a

clearance of 0 ± 0.5mm. (Fig.1).

(5) At that point, LED must be turned on

(Fig.2).

[Adjustment]

(1) Loosen four set screws (a) and remove

bed cover A (Fig.3).

(2) Remove four set screws (b) and remove

the base cover rear L. (Fig.4).

(3) Remove three set screws (c) and

remove the base cover front L (Fig.4).

(4) If the LED is not turned on, loosen the

set screw (d) of the thread trimming drive

lever and adjust the clearance between

the lever and stopper to 0.5mm (Fig.2).

Then perform the thread trimming to

check the standby position of the thread

catcher.

Note: At this time, vertical position of the

thread trimming drive lever must be

0~0.1mm from the motor spacer.

(5) If the LED is not turned on and the

clearance between the lever and

stopper is 0.5mm, loosen the set screw

of the drive arm, set the thread catcher

at 0 ± 0.5mm from the thread cutter and

tighten the set screw of the drive arm.

Then perform the thread trimming to

check the standby position of the thread

catcher.

0

±

0.5mm

FIG.1

FIG.2

FIG.3

LED

(d)

Thread

Trimming

drive lever

0.5mm

Stopper

-26-

Summary of Contents for ESP9000

Page 1: ...SERVICE MANUAL Embroidery Machine ESP9000 15 needles...

Page 2: ......

Page 13: ...FIG 3 48...

Page 24: ...FIG 4 59...

Page 36: ...Connection of connector CN 10 Must be connected correctly Replace See P 47 CN10 11...

Page 40: ...Picker height C 7 9 mm when piker solenoid is ON Adjust See P 27 15...

Page 58: ...FIG 2 FIG 3 201 3 0 1 0 3 mm 22...

Page 63: ...FIG 4 e Drive arm FIG 5 27...

Page 70: ...FIG 3 34...

Page 72: ...FIG 2 FIG 3 201 3 0 1 0 3 mm 22...

Page 74: ...FIG 2 FIG 3 Needle bar Stopper Needle bar Connecting stud 24...

Page 77: ...FIG 4 e Drive arm FIG 5 27...

Page 84: ...FIG 3 34...

Page 86: ...FIG 4 31...

Page 88: ...FIG 4 33...

Page 90: ...FIG 2 35...

Page 93: ...2 a Sensor arm 3 38...

Page 95: ...FIG 3 FIG 4 VR6 Power supply board 40...

Page 97: ...FIG 3 FIG 4 0 5 to 0 8mm 0 2mm or less Hook support hook support 37...

Page 100: ...FIG 4 40...

Page 103: ...FIG 2 Needle bar c Top dead center stopper needle bar connecting stud FIG 3 43...

Page 105: ...FIG 5 45...

Page 111: ...Printed in Japan 2002 8...