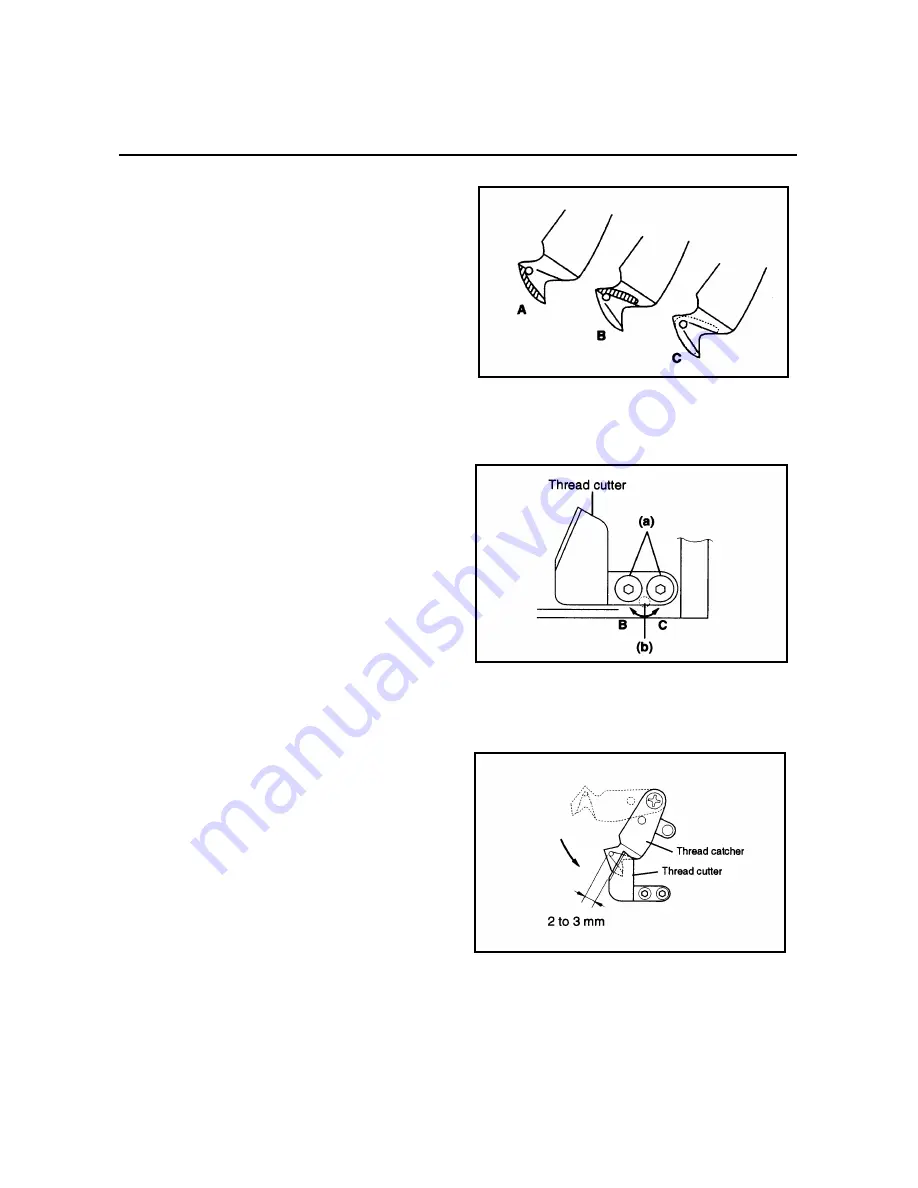

[Adjustment]

If the felt pen marking on the thread

catcher looks like A or B, adjust the angle

of the thread cutter as necessary then

adjust the blade pressure (Fig.4).

1) If the felt pen marking looks like A

(Fig.4).

(1)

Turn adjusting screw (b) in

direction B and, while steadying the

thread cutter by hand, turn

adjusting screw (b) in direction C

just so the screw tip barely touches

the thread cutter (Fig.5).

(2)

While steadying the thread cutter

by hand, tighten set screws (a)

alternately and evenly until the

cutter is fixed firmly (Fig.5).

2) If the felt pen marking looks like B

(Fig.4),

(1) Slightly loosen two set screws (a)

(Fig.5).

(2) While steadying the thread cutter

by hand, turn adjusting screw (b)

in direction C just so the screw tip

barely touches the thread cutter

(Fig.5).

(3) While steadying the thread cutter

by hand, tighten set screws (a)

alternately and evenly until the

cutter is fixed firmly (Fig.5).

3) If the felt pen marking looks like C,

adjust the blade pressure (Fig.4).

(1) If the clearance is less than 2mm,

slightly loosen the right-side set

screw (a), tighten the left-side set

screw (a), then tighten the thread

cutter in position with the right-side

set screw (a)(Fig.5 and 6).

(2) If the clearance is larger than

3mm, slightly loosen the left-side

set screw (a), tighten the right-side

set screw (a), then tighten the thread

cutter in position with the left-side set

screw (a) (Fig.5 and 6).

3..ADJUSTMENT

FIG.4

FIG.5

-29-

Summary of Contents for ESP9000

Page 1: ...SERVICE MANUAL Embroidery Machine ESP9000 15 needles...

Page 2: ......

Page 13: ...FIG 3 48...

Page 24: ...FIG 4 59...

Page 36: ...Connection of connector CN 10 Must be connected correctly Replace See P 47 CN10 11...

Page 40: ...Picker height C 7 9 mm when piker solenoid is ON Adjust See P 27 15...

Page 58: ...FIG 2 FIG 3 201 3 0 1 0 3 mm 22...

Page 63: ...FIG 4 e Drive arm FIG 5 27...

Page 70: ...FIG 3 34...

Page 72: ...FIG 2 FIG 3 201 3 0 1 0 3 mm 22...

Page 74: ...FIG 2 FIG 3 Needle bar Stopper Needle bar Connecting stud 24...

Page 77: ...FIG 4 e Drive arm FIG 5 27...

Page 84: ...FIG 3 34...

Page 86: ...FIG 4 31...

Page 88: ...FIG 4 33...

Page 90: ...FIG 2 35...

Page 93: ...2 a Sensor arm 3 38...

Page 95: ...FIG 3 FIG 4 VR6 Power supply board 40...

Page 97: ...FIG 3 FIG 4 0 5 to 0 8mm 0 2mm or less Hook support hook support 37...

Page 100: ...FIG 4 40...

Page 103: ...FIG 2 Needle bar c Top dead center stopper needle bar connecting stud FIG 3 43...

Page 105: ...FIG 5 45...

Page 111: ...Printed in Japan 2002 8...