10-

3

.

Test Operation

10-

3

-1.

Gas Leak Test

Check the flare nut connections for gas leaks with a

gas leak detector and/or soapy water.

Fig. 10-

3

-1

10-

3

-2.

Test Operation

Fig. 10-

3

-2

10-

3

-3.

Setting the Auto Restart

This product is designed so that, after a power

failure, it can restart automatically in the same

operating mode as before the power failure.

NOTE

The product was shipped with Auto Restart function

in the OFF position. Turn it ON as required.

1) Push and hold the RESET button for about

3 seconds. After 3 seconds, three short electric

beeps will be heard to inform you that the Auto

Restart has been selected.

2) To cancel the Auto Restart, follow the steps

described in the section Auto Restart Function of

the Owner’s Manual.

10-

3

-4.

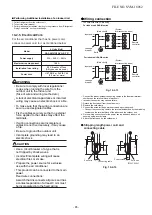

Remote Control A-B Selection

Fig. 10-

3

-3

To switch the TEST RUN (COOL) mode, press

RESET button for 10 sec.

(The beeper will make a short beep.)

RESET button

•

When two indoor units are installed in the same room or

adjacent two rooms, if operating a unit, two units may

receive the remote control signa

l

simultaneously and

operate. In this case, the operation can be preserved

by setting either one remote control to B setting.

(Both are set to A setting in factory shipment.)

•

The remote control signal is not received when the

settings of indoor unit and remote control are different.

•

There is no relation between A setting/B setting and A

room/B room when connecting the piping and cables.

<Remote control A-B selection>

To separate using of remote control for each indoor unit

in case of 2 air conditioners are installed nearly.

<Remote Control B Setup>

1.

Press [RESET] button on the indoor unit to turn the air

conditioner ON.

2.

Point the remote control at the indoor uni

t.

3.

4. Press [MODE] during pushing [CHECK]. "B" will show

on the display and "00" will disappear and the air

conditioner will turn OFF. The Remote Control B

is memorized [Picture ).

Push and hold [CHECK] button on the Remote Control

by the tip of the pencil. "00" will be shown on the display

(Picture )

1

2

NOTE :

1. Repeat

previous

step to reset Remote

Control to be A.

2.

Remote Control A has not "A" displa

y.

3.

Default setting of Remote Control fr

om

factory is A.

1

2

Check places for indoor unit

Check places for outdoor unit

FILE NO. SVM-18052

- 68 -