CAUTION

•

KEEP IMPORTANT 6 POINTS FOR

PIPING WORK.

Take away dust and moisture (inside

of the connecting pipes).

Tighten the connections (between

pipes and unit).

Evacuate the air in the connecting

pipes using a VACUUM PUMP.

Check gas leak (connected points).

Be sure to fully open the packed

valves before operation.

Reusable mechanical connectors

and flared joints are not allowed

indoors. When mechanical

connectors are reused indoors,

sealing parts shall be renewed.

When flared joints are reused

indoors, the fl are part shall be

refabricated.

■

Air Purge

From the sake of environmental protection, use a vacuum pump to extract

the air during installation.

* Prepare a 4 mm hexagon wrench.

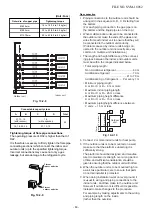

1. Connect a charge hose.

•

•

Make sure that the Handle Hi of the gauge manifold valve is closed fully.

Connect the port of the gauge manifold valve and the service port (Valve

core (Setting Pin)) using the charge hose.

NOTE

If a control valve or charge valve is attached to the charge hose, leak

of R

32

refrigerant can be avoided.

2. Open the Handle Low of the gauge manifold valve fully, then operate the

vacuum pump.

• Loosen the

fl

are nut of the at the gas end a little to make sure that air is

taken in, then tighten the nut.

• If you

fi

nd air is not taken in, make sure that the charge hose is

connected to the port(s) securely.

• Perform extraction for about 15 or more minutes and make sure that the

compound pressure gauge reading is –101 kPa (–76 cmHg).

• If the compound pressure gauge reading is not –101 kPa (–76 cmHg),

there is a possibility air is being taken in from the port(s).

• Make sure that the charge hose is connected to the port(s) securely.

3. Close the Handle Low of the gauge manifold valve fully, then stop

operating the vacuum pump.

• Leave the gauge and pump as they are for 1 or 2 minutes, then make

sure that the compound pressure gauge reading stays at –101 kPa

(–76 cmHg).

• You need not add refrigerant.

4. Disconnect the charge hose from the service port, then open the valve

stem fully using a 4 mm hexagon wrench.

Hexagon wrench is

required.

Service port cap

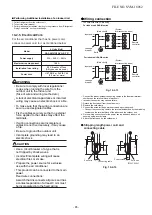

5. Tighten the service valve stem cap and service port cap securely.

Valve stem cap

CAUTION

Use a torque wrench and tighten the nut at

the speci

fi

ed torque value.

Fig. 10-2-

11

■

Insulation of the Refrigerant Pipes

•

Insulate the refrigerant pipes for liquid and gas separately.

Heat-proof bubble polyethylene

Underground piping: 10t

(Laying the pipes on the wall,

ceiling, or under the

fl

oor)

6. Tighten all the caps on the valves securely, then perform a gas leak

inspection.

• The cap with the 9.52 mm outer diameter is available in two sizes in

accordance with the type of packed valve for which the cap is used.

The tightening torque depends on the width across

fl

ats of the cap so

check it in the table below.

Service valve

Tighten torque

Valve stem cap

Service port cap

mm

N•m

kgf•m

N•m

kgf•m

Liquid side

(9.52)

H19 mm

14 to 18

1.4 to 1.8

H22 mm

33 to 42

3.3 to 4.2

Gas side (12.7)

33 to 42

3.3 to 4.2

14 to 18

1.4 to 1.8

Pressure gauge

Manifold valve

Handle Hi

(Keep full closed)

Charge hose

Service valve at

the liquid side

Vacuum pump adapter

for counter-

fl

ow

prevention

Charge hose

Service port

(Valve core (Setting pin))

Service valve at the gas

side

Compound pressure gauge

–101 kPa (–76 cmHg)

Handle Low

Vacuum pump

-

-

■

Gas Leak Inspection

•

Perform a gas leak inspection for the

fl

are nut connections, valve

stem connection, and service port cap without fail.

•

Use a leak detector exclusively manufactured for R

32

.

Flare nut connections (Indoor unit)

Check places for outdoor unit

FILE NO. SVM-18052

- 64 -

Fig. 10-2-

11

Fig. 10-2-

12