0

˚C

-

1˚C

–5˚C

–6˚C

OFF

20 W

65 W

Outdoor temperature To

Winding/Coil

heating amount

–5°C

0’

29’ 35’

90’

6

hours

–8°C

–10°C

–20°C

Operation time

(Minute)

Start of heating operation

*

Outdoor heat

exchanger temperature

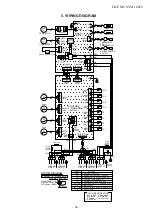

C zone

A zone

D zone

E zone

B zone

10’ 15’

Item

5.

Winding/Coil

heating control

6

.

Defrost control

(Only in heating

operation)

7

.

Compressor

protective

control

Operation flow and applicable data, etc.

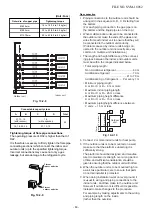

When the outdoor temperature is low, the windings/

coils are heated to ensure compressor reliability.

(This function removes frost adhered to the outdoor

heat exchanger.)

The temperature sensor of the outdoor heat ex-

changer (Te sensor) judges the frosting status of the

outdoor heat exchanger and the defrost operation is

performed with 4-way valve reverse defrost system.

* The minimum value of Te sensor 10 to 15 minutes after start of

operation is stored in memory as Te0 and Te1. (–10°C < Te1

≤

10°C)

Table 1

1) This control purposes to raise the operation frequency until 36Hz for 2 minutes in order to

protect the compressor (Prevention of oil accumulation in the refrigerating cycle) when the status

that the operation frequency is 36Hz or less has continued for 10 hours was calculated.

The operation frequency follows the normal indoor command after controlling.

2) Although the compressor may stop by THERMO-OFF control when the room temperature varies

and then attains the set temperature by this control, it is not abnormal.

3) During this control works, it stopping the operation by the remote controller, the operation does

not continue.

Description

Winding/Coil heating is performed when

the following conditions are met.

Condition 1 :

When the discharge sensor temperature

(Td) is less than 30°C.

Condition 2 :

When the outdoor sensor temperature (To)

is as shown in the left figure.

The necessity of defrost operation is

detected by the outdoor heat exchanger

temperature. The conditions to detect the

necessity of defrost operation differ in A,

B, C, D or E zone each. (Table 1)

<Defrost operation>

• Defrost operation in A to E zones

1) Stop operation of the compressor for

30 seconds.

2) Invert (OFF) 4-way valve 10 seconds

after stop of the compressor.

3) The outdoor fan stops at the same time

when the compressor stops.

4) When temperature of the indoor heat

exchanger becomes 38°C or lower,

stop the indoor fan.

<Finish of defrost operation>

• Returning conditions from defrost

operation to heating operation

1) Temperature of outdoor heat exchanger

rises to +8°C or higher.

2) Temperature of outdoor heat exchanger

is kept at +5°C or higher for 80 seconds.

3) Defrost operation continues for

10 minutes.

<Returning from defrost operation>

1) Stop operation of the compressor for

approx. 60 seconds.

2) Invert (ON) 4-way valve approx. 40

seconds after stop of the compressor.

3) The outdoor fan starts rotating at the

same time when the compressor starts.

A zone

B zone

C zone

D zone

E zone

When Te0 - TE

≥

2.5 continued for 2 minutes in A zone,

defrost operation starts.

When the operation continued for 2 minutes in B zone,

defrost operation starts.

When Te0 - TE

≥

3 continued for 2 minutes in C zone,

defrost operation starts.

When the operation continued for 2 minutes in D zone,

defrost operation starts.

When Te1 - TE

≥

1 continued for 2 minutes in E zone,

defrost operation starts.

FILE NO. SVM-18052

- 48 -