2

© 2009 TOSHIBA TEC CORPORATION All rights reserved

e-STUDIO181/211

ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 45

481

Paper

feeding

Automatic change of paper

source

PPC

1

<0-1>

SYS

Sets whether or not

changing the drawer

automatically to the

other drawer with the

paper of the same size

when paper in the

selected drawer has run

out.

0: OFF

1: ON

1

482

Paper

feeding

Feeding retry setting

ALL

0

<0-1>

M

0: ON

1: OFF

1

483

Laser

Pre-running rotation of

polygonal motor

ALL

0

<0-2>

SYS

Sets whether or not

switching the polygonal

motor from the standby

rotation to the normal

rotation when the

original is set on the

ADF or the platen cover

is opened.

0: Valid (when using

ADF and the origi-

nal is set manually)

1: Invalid

2: Valid (when using

ADF only)

1

486

Laser

Timing of auto-clearing of

polygonal motor pre-

running rotation

ALL

0

<0-2>

SYS

Switches the polygonal

motor to the standby

rotation when a certain

period of time has

passed from the pre-

running. At this code,

the period to switch the

status to the standby

rotation is set.

0: 15 sec.1: 30 sec.

2: 45 sec.

*

This setting is

effective when “0” or

“2” is set at 08-483.

1

502

Image

Error diffusion and dither

setting at photo mode

PPC

1

<0-1>

SYS

Sets the image

reproduction method at

photo mode.

0: Error diffusion

1: Dither

1

515

Fuser

Temperature setting of

warming-up

(Center thermistor)

ALL

9

<0-14>

M

0: 140°C 1: 145°C

2: 150°C 3: 155°C

4: 160°C 5: 165°C

6: 170°C 7: 175°C

8: 180°C 9: 185°C

10: 190°C

11: 195°C

12: 200°C

13: 205°C

14: 210°C

1

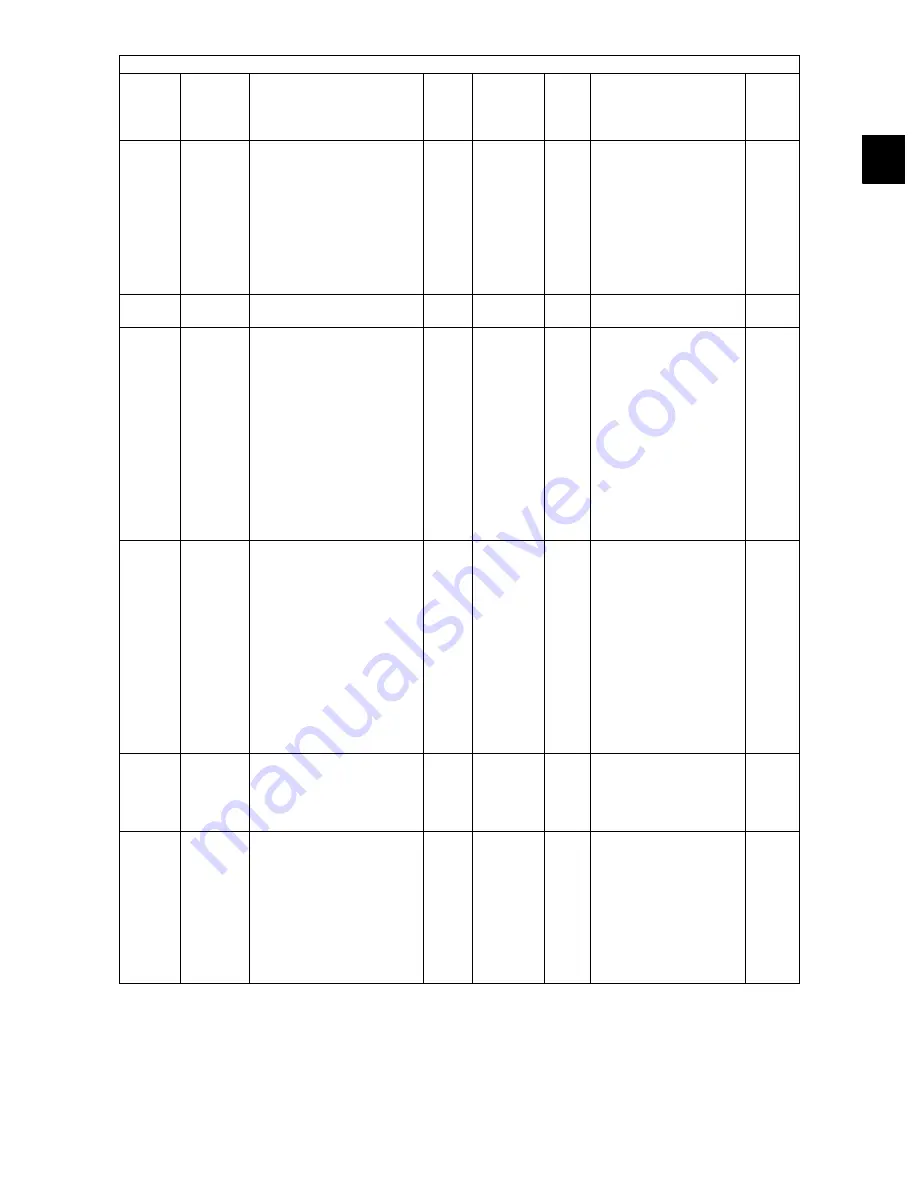

Setting mode (08)

Code

Classific

ation

Items

Funct

ion

Default

<Accept

able

value>

RAM

Contents

Proce

dure

Summary of Contents for e-STUDIO181

Page 14: ...e STUDIO181 211 2009 TOSHIBA TEC CORPORATION All rights reserved CONTENTS 4 ...

Page 138: ...e STUDIO181 211 2009 TOSHIBA TEC CORPORATION All rights reserved ADJUSTMENT 3 56 ...

Page 202: ...e STUDIO181 211 2009 TOSHIBA TEC CORPORATION All rights reserved TROUBLESHOOTING 5 48 ...

Page 220: ...e STUDIO181 211 2009 TOSHIBA TEC CORPORATION All rights reserved POWER SUPPLY UNIT 7 4 ...

Page 222: ...e STUDIO181 211 2009 TOSHIBA TEC CORPORATION All rights reserved WIRE HARNESS CONNECTION 8 2 ...

Page 225: ......

Page 226: ......