User’s Manual

7

Part 1

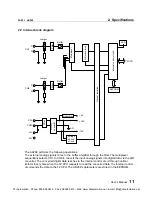

8 Channel Analog Input Module

AD268

1. Introduction, 8

2. Specifications, 10

3. Input Type Setting, 12

4. Wiring, 14

5. I/O Allocation and Programming, 17

6. Parameters, 24

7. Troubleshooting, 32

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: [email protected]