g029758

Figure 59

1.

Tension tube

3.

Tensioning screw

2.

Locking bolt

4.

Using a 1/2 inch drive ratchet, turn the tensioning

screw until the tension block aligns with the

green guide on the decal or is 1.3 cm (1/2 inch)

away from the rear of the tension tube slot

(

).

Note:

Turning the screw counter-clockwise

tightens the track; turning the screw clockwise

loosens the track.

5.

Align the closest notch in the tension screw to

the locking-bolt hole and secure the screw with

the locking bolt and nut (

6.

Repeat the procedure for the other track.

7.

Drive the machine, then park the machine on a

level surface, engage the parking brake, shut off

the engine, and remove the key.

8.

Verify that the tension block aligns with the

green guide of the decal or is 1.3 cm (1/2 inch)

away from the rear of the tension tube for both

tracks (

). Adjust if necessary.

Replacing the Tracks

Machines with Narrow-Width Tracks

Replace the tracks when they are badly worn.

1.

Remove any attachments.

2.

Park the machine on a level surface, ensuring

that only 1 sprocket half is engaged with the

track (

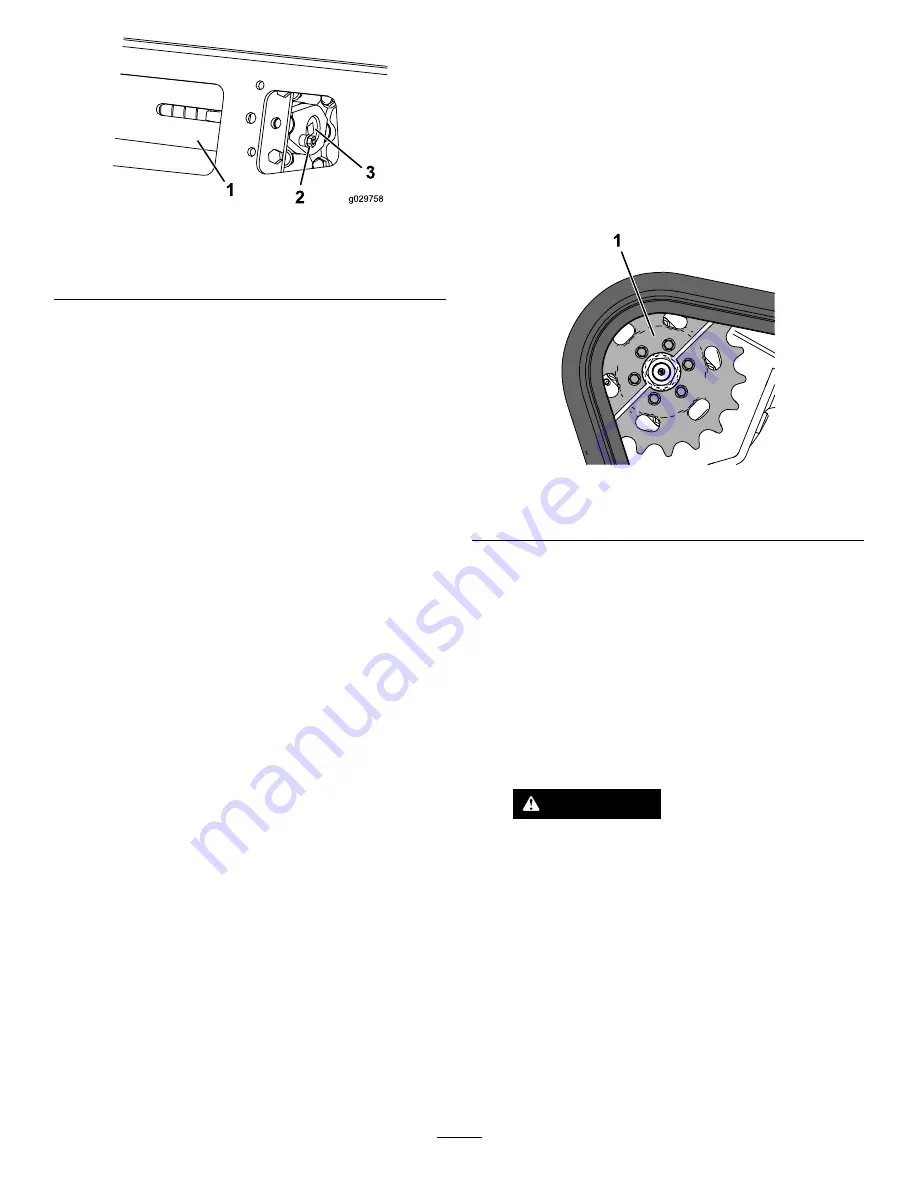

g259714

Figure 60

1.

Sprocket half

3.

Engage the parking brake.

4.

Lower the loader arms so that they are

approximately 20 to 25 cm (8 to 10 inches)

above the frame.

5.

Shut off the engine and remove the key.

6.

Raise the machine off the ground until you

can access the inside of the track beneath

the machine. Support the machine using jack

stands.

Note:

Use jack stands rated for your machine.

WARNING

Mechanical or hydraulic jacks may fail to

support the machine and cause serious

injury.

Use jack stands when supporting the

machine.

7.

Remove the locking bolt, spacer, and nut (

8.

Using a 1/2-inch drive ratchet, release the

drive tension by turning the tensioning screw

clockwise (

and

).

40

Summary of Contents for TX 1000 Compact Tool Carrier

Page 54: ...Schematics g240932 Electrical Schematic Rev B 54 ...

Page 55: ...g260360 Hydraulic Schematic Rev D 55 ...

Page 56: ...Notes ...

Page 57: ...Notes ...

Page 58: ...Notes ...