to match the armature and needs to continue to

match after the shim is removed to ensure proper

brake torque.

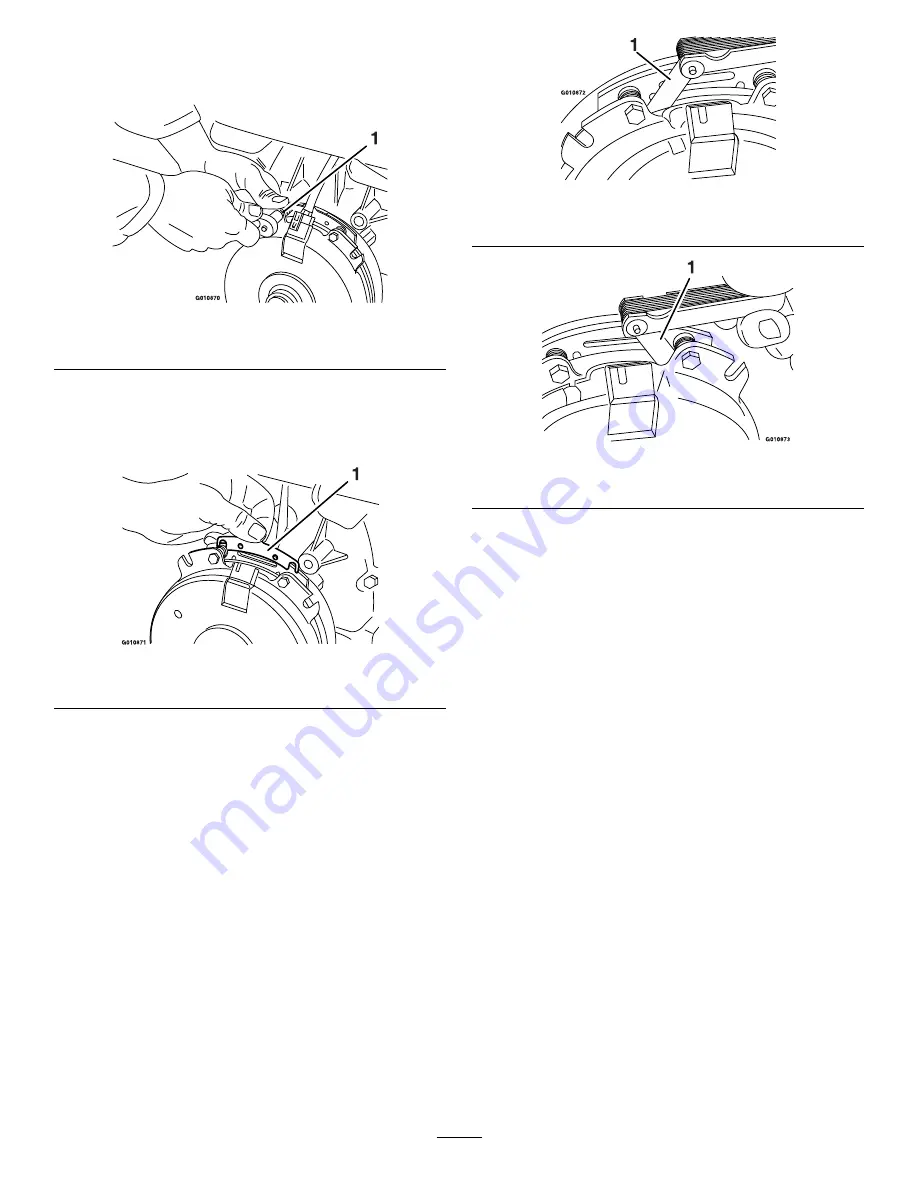

Figure 68

1.

Brake mounting bolt

B.

Using needle nose pliers, or by hand, take hold

of the tab and remove the shim (Do Not discard

the shim until proper clutch function has been

confirmed).

Figure 69

1.

Shim

C.

Using a pneumatic line, blow out any debris

from under the brake pole and around the brake

spacers.

D.

Re-torque each bolt (M6 x 1) to 10 ft-lb (13 N-m)

+/-0.5 ft-lb (0.7 N-m).

E.

Using a 0.010 inch thick feeler gauge, verify that

a gap is present between the rotor and armature

face on both sides of the brake pole as shown.

(Due to the way the rotor and armature faces

wear (peaks and valleys) it is sometimes difficult

to measure the true gap.)

Figure 70

1.

Feeler gauge

Figure 71

1.

Feeler gauge

•

If the gap is less than 0.010 inch, then reinstall

the shim and reference the

Troubleshooting

section.

•

If the gap is sufficient, proceed to the safety

check in step F.

F.

Perform the following safety check:

i.

Sit on the seat and start the engine.

ii.

Make sure the blades Do Not engage

with the PTO switch “off ” and the clutch

disengaged.

If the clutch does not disengage,

reinstall the shim and reference the

Troubleshooting

section.

iii.

Engage and disengage the PTO switch

ten consecutive times to ensure the clutch

is functioning properly. If the clutch

does not engage properly, reference the

Troubleshooting

section.

46

Summary of Contents for 74901 Z Master 5000

Page 66: ...Schematics Wire Diagram Rev A 66 ...

Page 67: ...Notes 67 ...