6.

Then tighten nut until the next set of slots line up

with the cross hole in shaft. Do not loosen nut to

align the slot. If required, tighten to the next set

of slots.

7.

Install a new cotter pin.

Note:

Do Not use anti-seize on wheel hub.

Adjusting the Caster Pivot

Bearing

Service Interval:

Every 500 hours/Yearly (whichever comes

first)

1.

Disengage the blade control switch (PTO), move the

motion control levers to the neutral locked position

and set the parking brake.

2.

Stop the engine, remove the key, and wait for all moving

parts to stop before leaving the operating position.

3.

Remove the dust cap from caster and tighten lock nut

(Figure 65).

4.

Tighten the locknut until the spring washers are flat and

then back off a 1/4 turn to properly set the pre-load on

the bearings (Figure 65).

Important:

Make sure the spring washers are

installed correctly as shown in Figure 65.

5.

Install the dust cap (Figure 65).

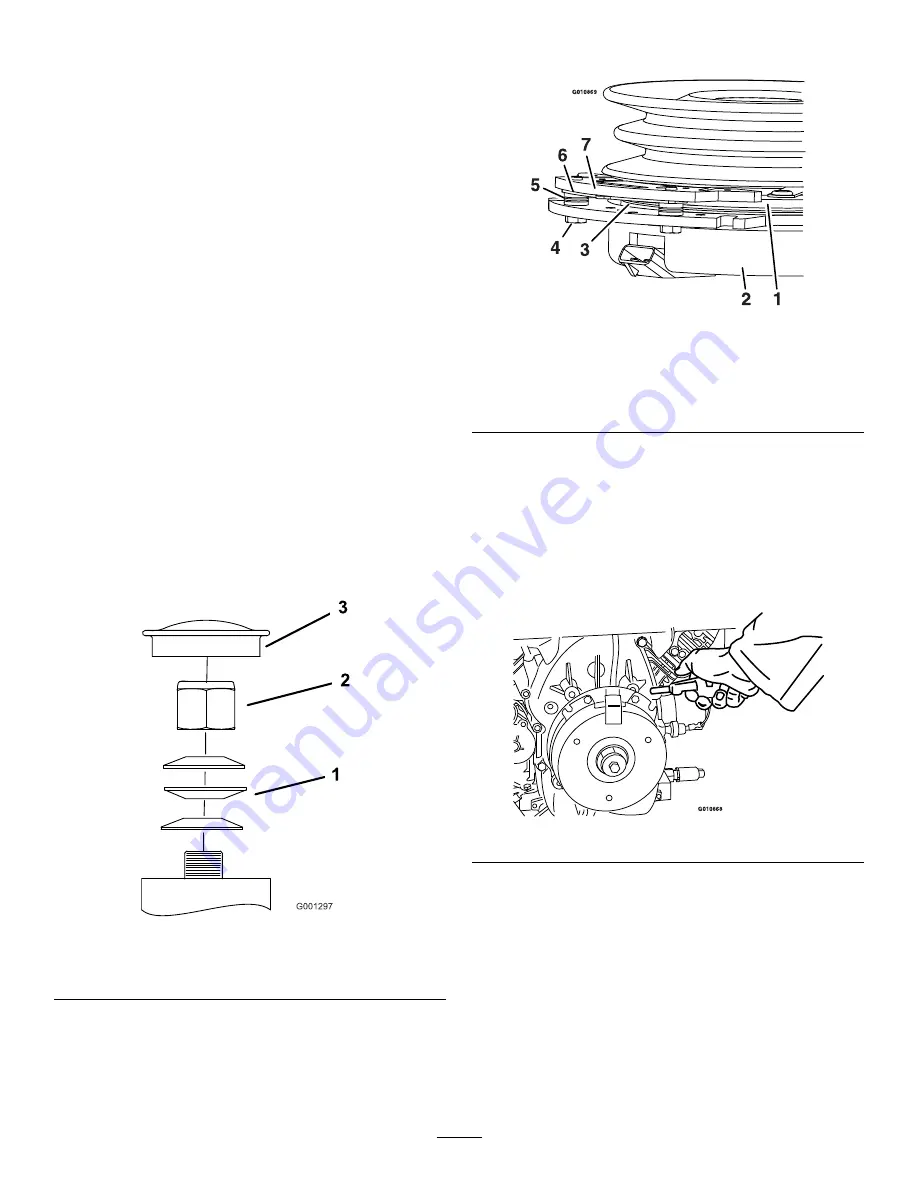

Figure 65

1.

Spring Washers

3.

Dust Cap

2.

Lock Nut

Using the Clutch Shim

Some later model year units have been built with clutches that

contain a brake shim. When the clutch brake has worn to the

point where the clutch no longer engages consistently, the

shim can be removed to extend the clutch life.

Figure 66

1.

Armature

5.

Brake spacer

2.

Field shell

6.

Re-gap shim

3.

Rotor

7.

Brake pole

4.

Brake mounting bolt

Removing the Clutch Shim

1.

Stop the engine, wait for all moving parts to stop, and

remove the key. Engage the parking brake. Allow

the machine to cool completely before starting these

instructions.

2.

Using an air compressor, blow out any debris from

under the brake pole and around the brake spacers.

Figure 67

3.

Check the condition of the wire harness leads,

connectors, and terminals. Clean or repair as necessary.

4.

Verify that 12V is present at the clutch connector when

the PTO switch is engaged.

5.

Measure the gap between the rotor and armature. If

the gap is greater than .04 inch (1 mm), proceed with

the following steps:

A.

Loosen both brake mounting bolts one-half to

one full turn as shown below.

Note:

Do Not remove the brake pole from the

field shell/armature. The brake pole has worn

45

Summary of Contents for 74901 Z Master 5000

Page 66: ...Schematics Wire Diagram Rev A 66 ...

Page 67: ...Notes 67 ...